Polishing-free and gluing-free shoe and shoemaking method thereof

A technology for rubber shoes and shoe uppers, which is applied to footwear, soles, heel pads, etc. It can solve the problems of human injury and cost increase, and achieve the effect of saving labor costs and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

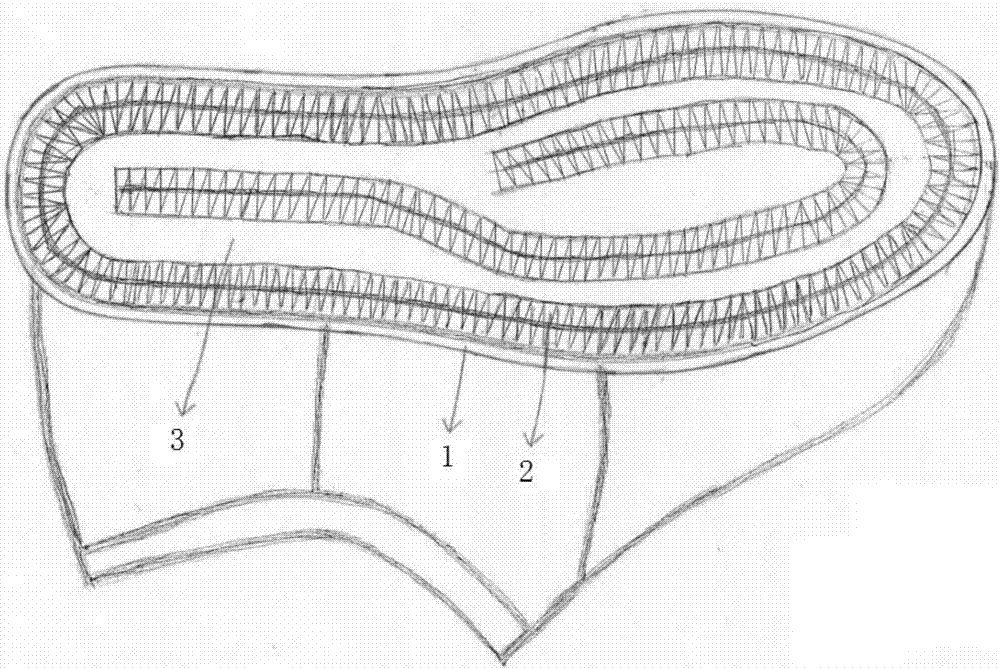

[0016] Specific embodiment one: a kind of non-wearing and glue-free shoe-making method, it comprises midsole, outsole and the upper of a shoe that links to each other with midsole, and it is to comprise the following steps:

[0017] 1. Use a line of 0.1 to 0.3 cm, use the edge machine to make a curve with a code width of 0.5 to 1.5 cm in the A area of the midsole, and continue the curve with a code width of 0.5 to 1.5 cm in the remaining space in this area;

[0018] 2. Connect the upper of the shoe with the B area of the midsole processed in step 1;

[0019] 3. Place the midsole connected to the upper in the melted outsole for connection, and then cool to room temperature to complete the connection of the midsole, outsole and upper;

[0020] Among them, the midsole is bounded by 0.4 to 0.6 cm from the edge of the midsole, the area close to the edge of the midsole is the B area, and the area far from the edge of the midsole is the A area.

specific Embodiment approach 2

[0021] Specific embodiment two: the difference between this embodiment and specific embodiment one is that: in step one, the curve using the edge machine code is a curve with a width of 0.8-1.2 cm. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0022] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the curve is a protruding and raised curve. Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com