Treatment device for paper manufacturing

A technology for processing devices and paper products, applied in grain processing, drying gas arrangement, lighting and heating equipment, etc., can solve the problems of wet waste paper, easy wear of serrated knives, easy clogging of shredded paper conveying pipes, etc., to improve efficiency, The effect of reducing manual operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

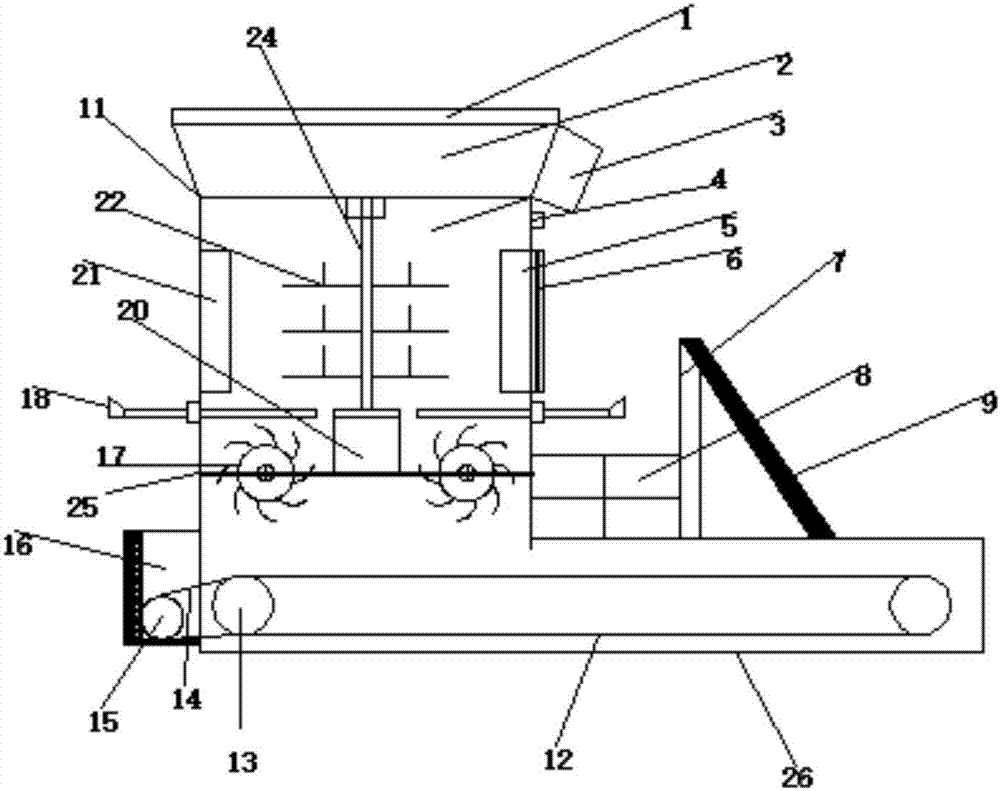

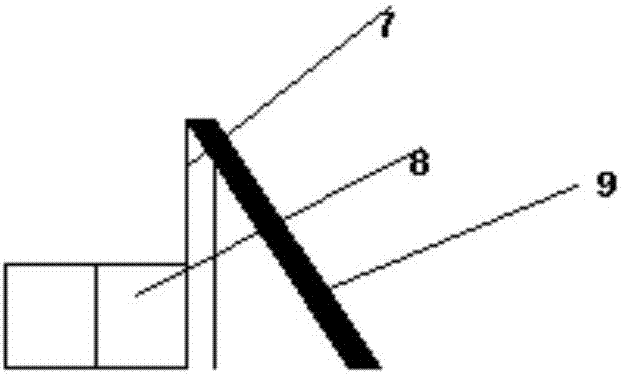

[0015] Such as Figure 1-2 As shown, a processing device for paper product processing includes a paper product feed hopper 2, a stirring shaft 24, a stirring motor 20, a drying fan 21, a magnet 5, a gate 18, an annular blade machine 17, a driving motor 15, and a conveyor belt 12. Solar panel 9, power storage box 8, LED lamp 3, machine body 11 and shredded paper conveying pipe 26, the top of the machine body 11 is fixed with a paper product feeding funnel 2, and one side of the paper product feeding funnel 2 is fixed A mounting frame is provided and an LED lamp 3 is installed in the mounting frame, a drying fan 21 is fixedly installed on one side of the body 11, a magnet 5 is fixedly installed on the other side of the body 11, and a support frame 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com