A jig for assembling server boards

A server board and jig technology, which is applied in the field of jigs for assembling server boards, can solve problems such as stress damage to components on the motherboard, uneven stress on the heat sink glue nails, and inability to assemble vertically. Weight, high work efficiency, and the effect of avoiding uneven force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

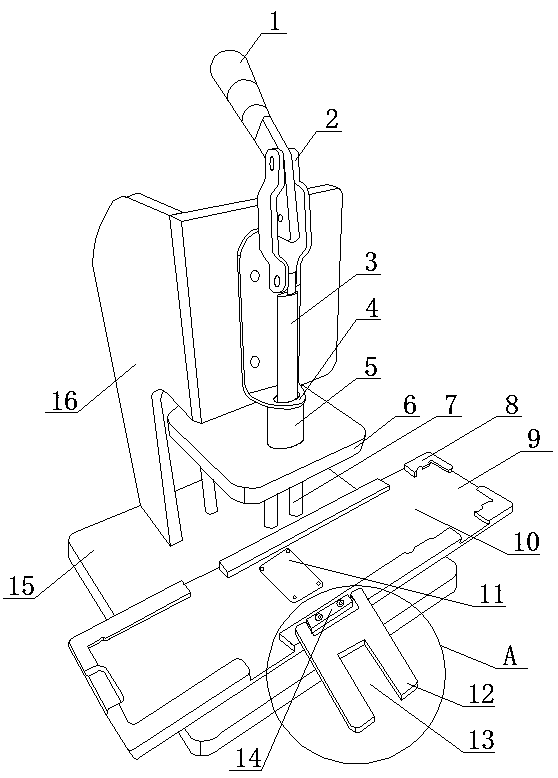

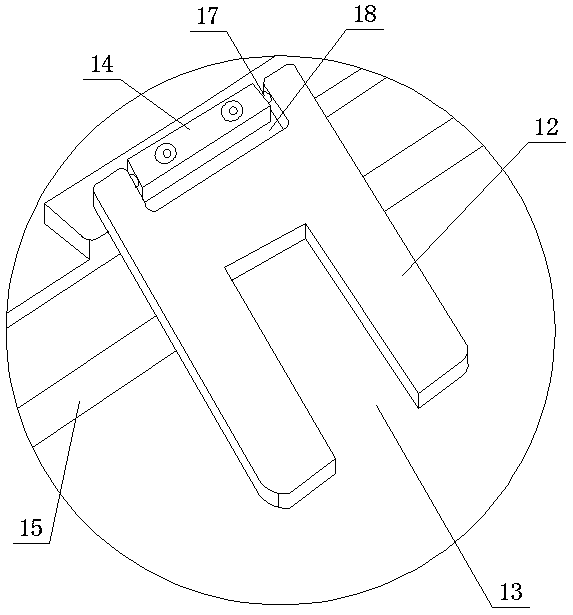

[0036] as attached figure 1 And attached figure 2 As shown, a fixture for assembling server boards of the present invention includes a pressing mechanism, a carrier and a buckle. The pressing mechanism includes a base 15, a bracket 16, a lifting plate 6 and a lifting mechanism. The bracket 16 is vertically fixed on the On the top surface of the base 15, the elevating mechanism is fixed on the top of the base 15 by a support 16, and the elevating plate 6 is fixed on the elevating mechanism, and the elevating mechanism can drive the elevating plate 6 to move up and down above the base 15; Tool plate 8 and carrier sheet 11, the top surface of carrier plate 8 is provided with the main board groove 10 that can accommodate mainboard, and the carrier sheet 11 that is used to place cooling fin is arranged in mainboard groove 10; Buckle includes limit plate 12 One of the side portions of the limiting plate 12 is the connecting side portion of the limiting plate 12, and the connecting...

Embodiment 2

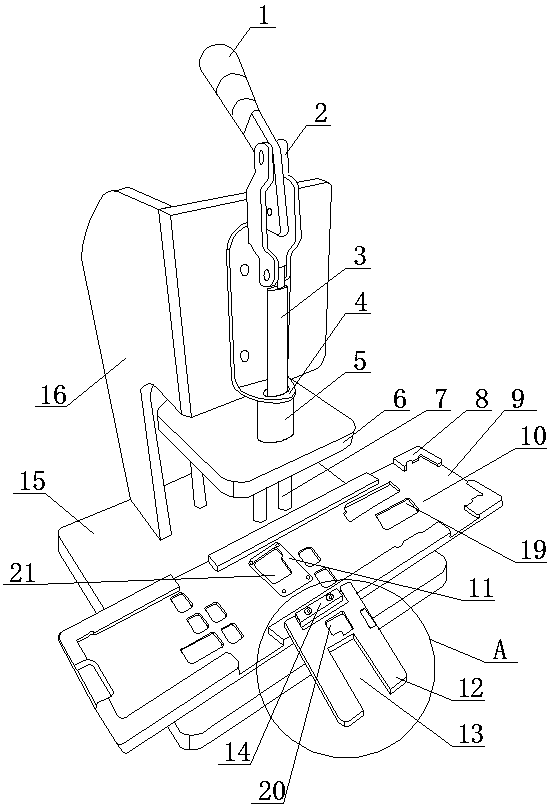

[0052] as attached image 3 And attached Figure 4 As shown, this embodiment is a further improvement on the basis of Embodiment 1. The difference between this embodiment and Embodiment 1 is that a plurality of avoidance grooves I19 are provided on the top surface of the groove 10 of the main board, and the above-mentioned avoidance grooves I19 Respectively correspond to the components on the back of the motherboard to be assembled one by one, so that when the motherboard is placed in the groove 10 of the motherboard, the components on the back of the motherboard are located in the corresponding avoidance groove I19, thereby protecting the back of the motherboard and The safety of components and parts on the main board; the top surface of the carrier sheet 11 is provided with a plurality of avoidance grooves III21, and a plurality of avoidance grooves II20 are provided on the side of the limit plate 12 that can face the carrier sheet 11. The above-mentioned avoidance grooves ...

Embodiment 3

[0055] as attached Figure 5 And attached Figure 6 As shown, this embodiment is a further improvement on the basis of Embodiment 2. The difference between this embodiment and Embodiment 2 is: the carrier plate 8 is provided with a plurality of strip-shaped through holes 22 that run through its top surface and bottom surface. The strip-shaped through holes 22 are distributed in the groove of the main board. The arrangement of the strip-shaped through holes 22 is convenient for reducing the weight of the carrier board 8 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com