High-stability hot pressure injection forming system

A high-stability, hot-pressure injection technology, used in ceramic molding machines, auxiliary molding equipment, die-casting molds, etc., can solve the problems of low yield of core hollow blade products, achieve significant improvement effects, and reduce slurry splashing , the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

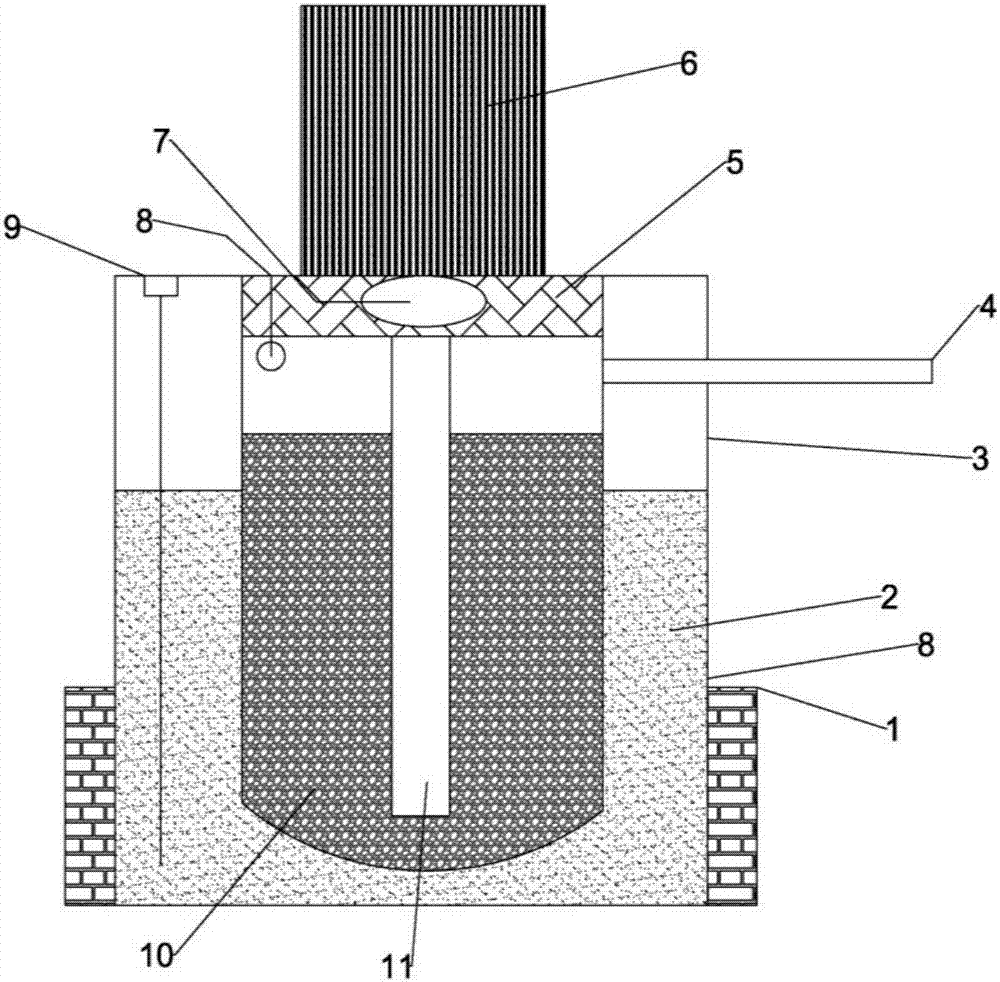

Embodiment 1

[0032] Open the heating medium liquid level monitoring device 9, and judge the corresponding heating medium addition amount according to the position of the liquid level displayed on the scale. Turn on the power, start the constant temperature heater 1, adjust the power to a certain temperature, heat the heating medium 2 through the heating tank 3, and monitor the temperature in the storage tank / pulp storage tank in real time according to the temperature sensor 8, and wait to be heated to a suitable temperature , start the air circuit device, compressed air at a certain pressure enters the stock tank / slurry tank through the air circuit system 4, and under the action of pressure, the slurry 10 enters the mold 6 from the slurry delivery pipe 11 through the solid mold ring 7, and passes through After a period of grouting and pressurization, close the air circuit device, deflate and take out the mold, condense, and complete an injection molding cycle after demoulding. The hot pres...

Embodiment 2

[0034] Turn on the power, judge and add an appropriate amount of heating medium according to the position of the liquid level displayed on the digital display panel, start the constant temperature heater 1, adjust the power to a certain temperature, heat the heating medium 2 through the heating tank 3, and use the temperature sensor 8 to real-time Monitor the temperature in the storage tank / pulp tank, and when it is heated to a suitable temperature, start the air circuit device, and the compressed air at a certain pressure enters the storage tank / pulp tank through the air system 4, under the action of pressure, the slurry 10 enters the mold 6 from the slurry delivery pipe 11 through the solid mold ring 7. After a period of grouting and maintaining pressure, close the air circuit device, deflate and take out the mold, condense, and complete an injection molding cycle after demoulding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com