Initial mixing device for PVC metalized thermal shrinkage film materials

A technology of heat shrinkable film and mixing device, which is applied in the field of initial mixing device of PVC metallized heat shrinkable film material, can solve the problems of metallized film quality, poor dispersion, poor compatibility, etc., and achieve the reduction of shear damage and dispersion effect Good, well-mixed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

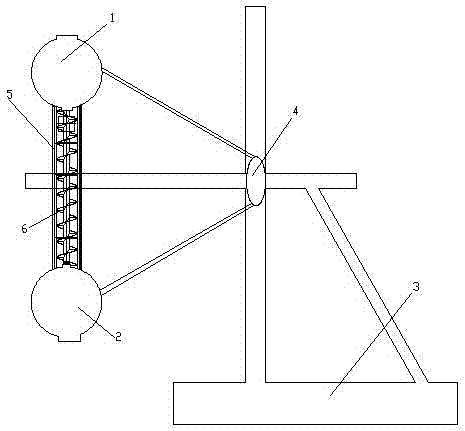

[0010] PVC metallized heat-shrinkable film material initial mixing device, the mixing device includes an upper silo 1, a lower silo 2, a support frame 3, a silo rotating mechanism 4 and a spiral body 5, and the spiral body 5 is connected to the upper silo 1 and the lower silo 2, the spiral body 5 is provided with a spiral cavity, and the spiral element 6 is arranged in the spiral cavity, and the silo rotation mechanism 4 is arranged on the support frame 3, and the The silo rotating mechanism 4 is provided with connecting shafts respectively fixed on the upper hopper 1 and the lower hopper 2, the upper hopper 1 and the lower hopper 2 are spherical hoppers, and the upper hopper 1 and the lower hopper The bin 2 is respectively provided with a material inlet and outlet and a spiral chamber inlet and outlet, and the inner diameter of the spiral chamber inlet and outlet is smaller than the inner diameter of the spiral chamber.

[0011] When the raw material in the upper bin 1 flows ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com