Micro wastewater purifier

A water purifier and micro-wastewater technology, applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem of crystalline substances, easy crystallization of RO membranes, membrane plugging, and salts Substances are easy to crystallize, accumulate and grow scale, etc., to achieve the effect of fast water flow, small space, and avoid accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

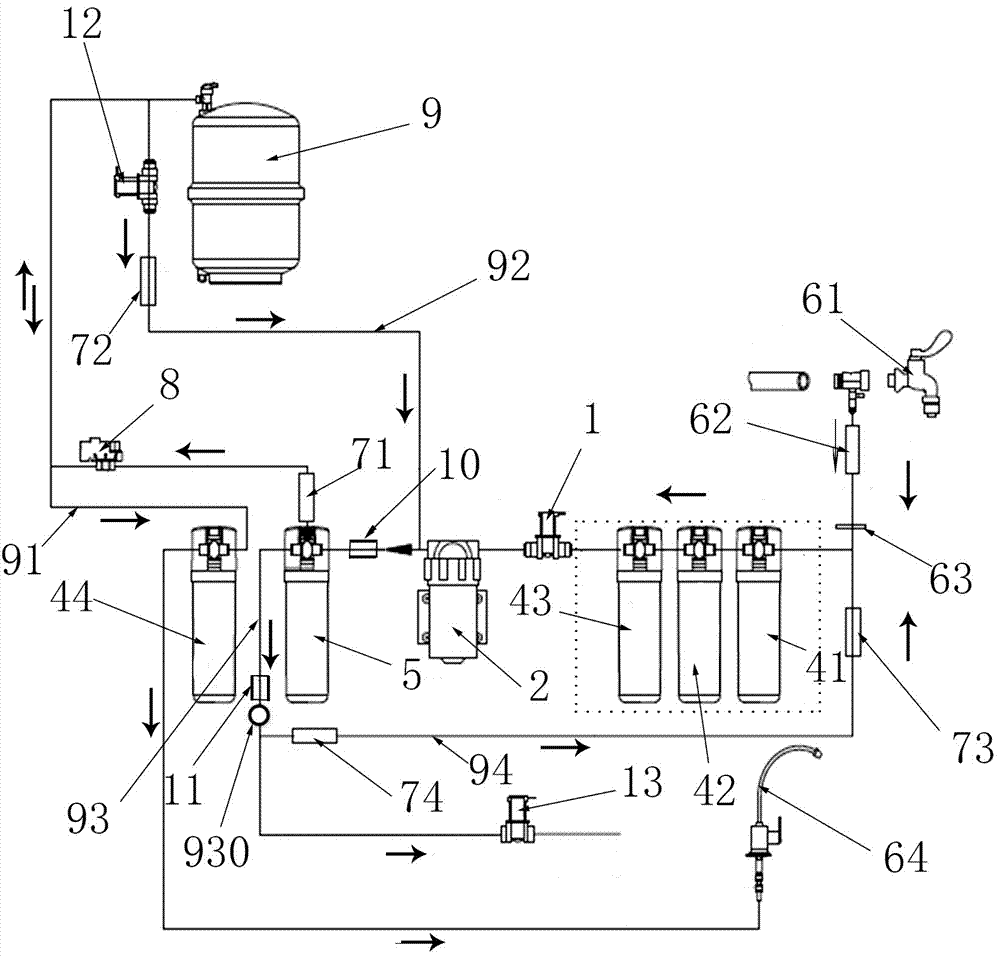

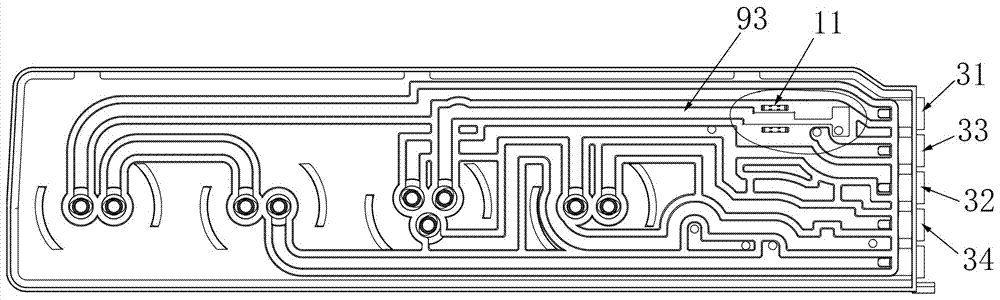

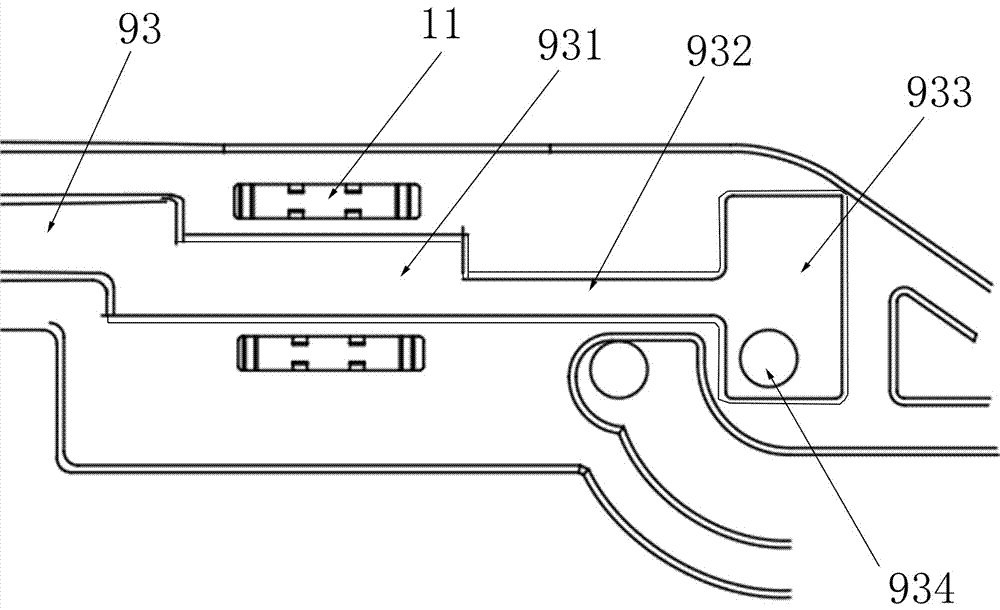

[0034] See attached picture. This embodiment includes a control module, a waterway board 3 and a filter module; the waterway board has a built-in preset passage, and various waterways described below are all arranged on the waterway board, and the filter module and various components are all installed on the waterway board; the waterway board 3 The side is provided with a raw water inlet 31, a pure water outlet 32, a concentrated water outlet 33 and a pressure tank connection port 34 connected to the preset passage. The water inlet solenoid valve 1, booster pump 2 and filter module are installed on the water circuit board 3 The filter module includes a pre-filter element and an RO filter element 5 , and the pre-filter element includes a PP filter element 41 , an activated carbon filter element 42 and an ultrafiltration membrane filter element 43 .

[0035] The raw water inlet 31 is connected to the water inlet tap 61, and the raw water inlet 31 is sequentially connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com