Method for preparing ITO sputtering target for TFT-LCD through controlling oxygen content

A sputtering target and oxygen content technology, which is applied in the field of preparation of ceramic targets for sputtering, can solve problems such as high sintering temperature at high temperature, harmful phases produced by targets, and unfavorable target resistivity, etc. The effect of small load and avoiding the loss of oxygen in the billet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

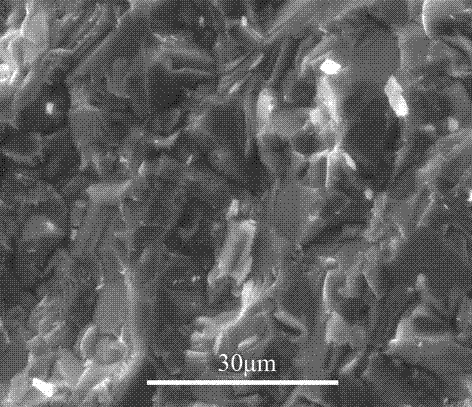

Image

Examples

Embodiment 1

[0026] Weigh a certain amount of ITO vaporized alloy powder with a tin dioxide content of 8.5%, a purity of ≧99.99%, and an average particle size of 50nm. Weigh a certain amount of deionized water, add surfactants, binders and other auxiliary agents, then add the ITO gasification alloy powder and carry out ball milling to prepare an ITO slurry with a solid content of 50%, and then mix the slurry Carry out granulation, and the granulated powder is in the shape of a solid sphere. The prepared granulated powder was put into a mold with a size of 435mm×900mm, and molded under the condition of 60MPa, and the holding time was 300s. Put the formed blank into a flexible sheath for vacuum sealing, put it into a cold isostatic press, and carry out isostatic pressing under the condition of 200MPa, with a holding time of 300s. Put the green body after isostatic pressing into the sintering furnace for micro-pressure sintering. The specific sintering process is as follows: heat up to 120°...

Embodiment 2

[0028] Weigh a certain amount of ITO vaporized alloy powder with a tin dioxide content of 9.5%, a purity of ≧99.99%, and an average particle size of 50nm. Weigh a certain amount of deionized water, add surfactants, binders and other auxiliary agents, then add the ITO gasification alloy powder and carry out ball milling to prepare an ITO slurry with a solid content of 55%, and then the slurry Carry out granulation, and the granulated powder is in the shape of a solid sphere. The prepared granulated powder was put into a mold with a size of 520mm×1100mm, and molded under the condition of 80MPa, and the holding time was 420s. Put the formed blank into a flexible sheath for vacuum sealing, put it into a cold isostatic press, and carry out isostatic pressing under the condition of 250MPa, with a holding time of 420s. Put the green body after isostatic pressing into the sintering furnace for micro-pressure sintering. The specific sintering process is as follows: heat up to 150°C a...

Embodiment 3

[0030] Weigh a certain amount of ITO vaporized alloy powder with a tin dioxide content of 10.5%, a purity of ≧99.99%, and an average particle size of 50nm. Weigh a certain amount of deionized water, add surfactants, binders and other auxiliary agents, then add the ITO gasification alloy powder and carry out ball milling to prepare an ITO slurry with a solid content of 60%, and then the slurry Carry out granulation, and the granulated powder is in the shape of a solid sphere. The prepared granulated powder was put into a mold with a size of 625mm×1300mm, and molded under the condition of 100MPa, and the holding time was 600s. Put the formed blank into a flexible sheath for vacuum sealing, put it into a cold isostatic press, and carry out isostatic pressing under the condition of 300MPa, with a holding time of 600s. Put the green body after isostatic pressing into the sintering furnace for micro-pressure sintering. The specific sintering process is as follows: heat up to 180°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com