A self-tightening mechanical automatic brake device

An automatic braking and self-tightening technology, applied in the direction of mechanical equipment, brake types, axial brakes, etc., can solve the problems of high cost, low reliability, high failure, etc., and achieve great economic application value, high reliability, and structure compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

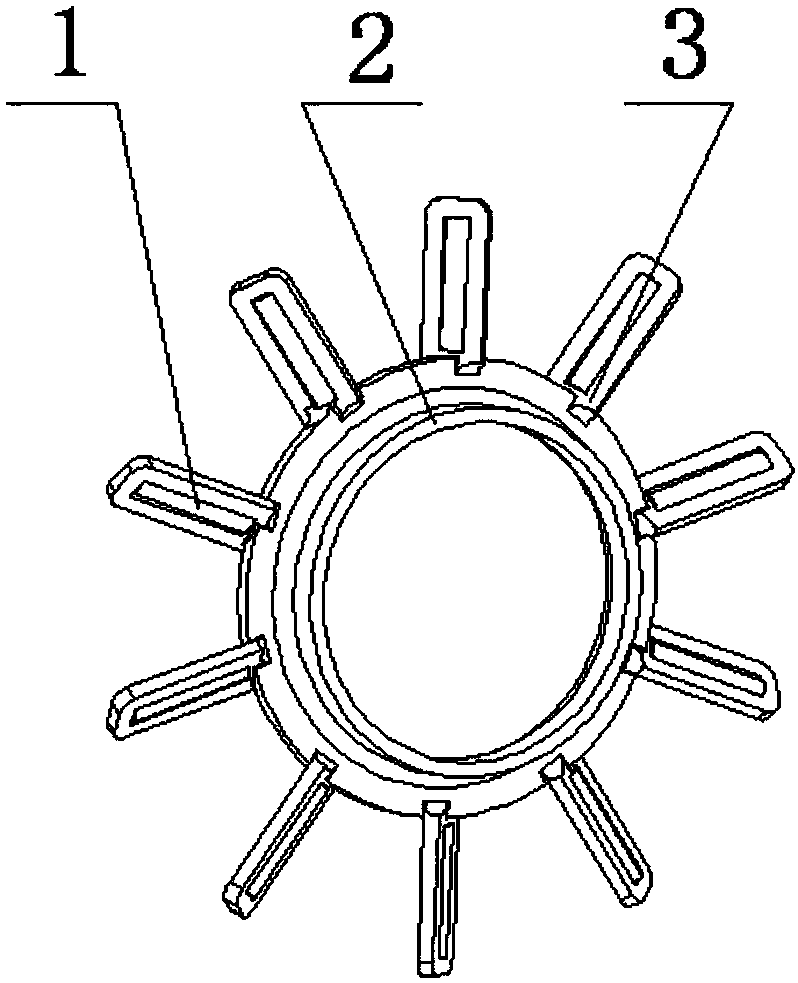

[0015] Provide a slanted needle roller assembly, the slanted needle roller assembly mainly includes a needle roller 1, a central ring 2, and a needle roller bracket 3; the central ring and the needle roller bracket form a petal-shaped structure, and each needle roller bracket is relatively The planes of the rings are all twisted at the same angle, and the needle rollers are supported on the needle roller support for rolling.

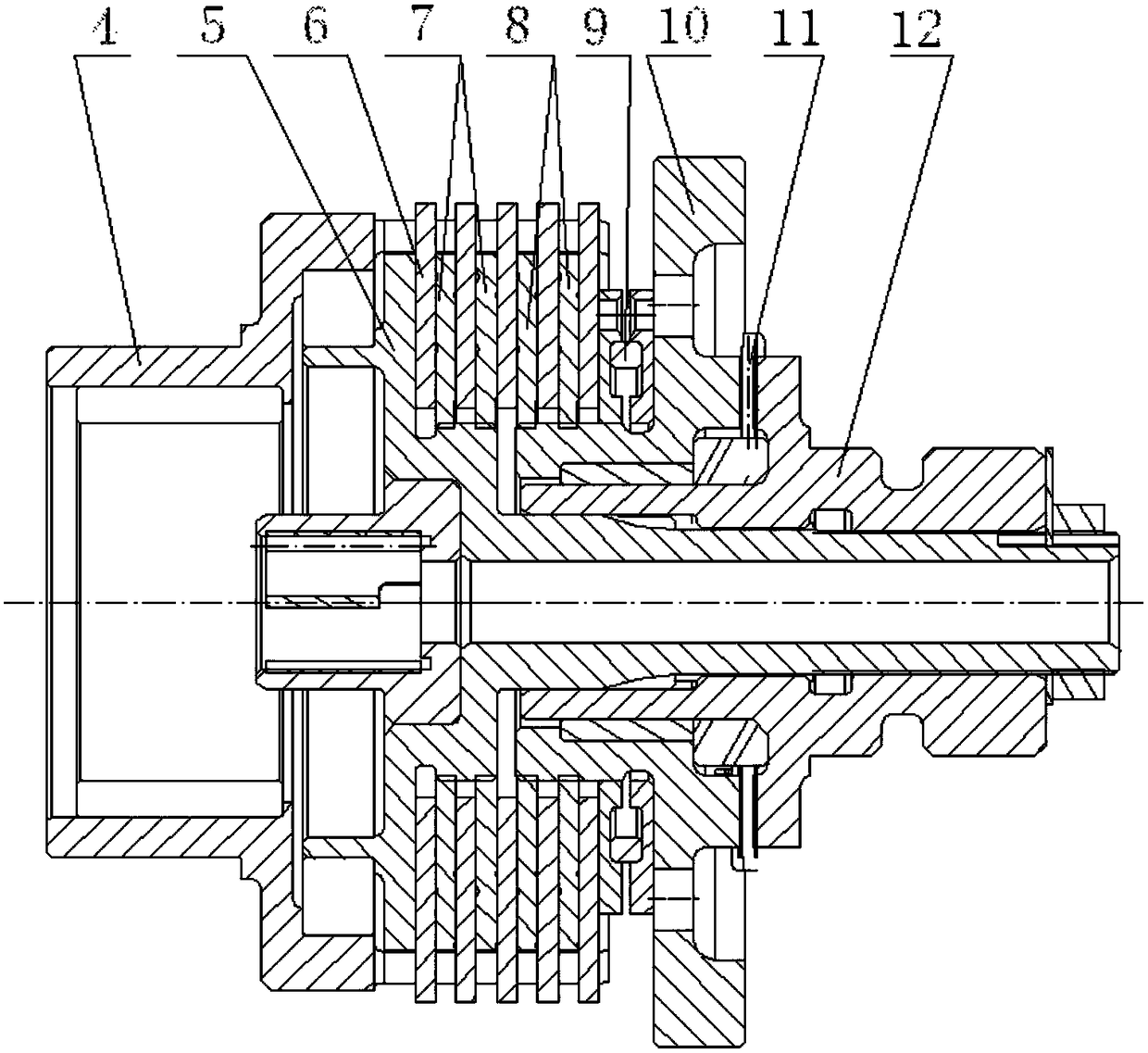

[0016] At the same time, a self-tightening mechanical automatic braking device is provided, which mainly includes a housing 4, a transmission shaft 5, a static friction plate 6, a first dynamic friction plate 7, a second dynamic friction plate 8, a spring 9, and a first gear 10 , the above-mentioned oblique needle roller assembly 11, the second gear 12; the spring 9 is arranged between the second moving friction plate 8 and the first gear 10, and the spring applies a pre-tightening force to the second moving friction plate;

[0017] The inner wall surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com