Gearbox lubricating pump used for rail vehicle

A technology for rail vehicles and gearboxes, applied in gear lubrication/cooling, lubricating pumps, engine lubrication, etc., can solve the problems of poor reliability and vehicle operation safety, and achieve the goal of improving reliability, vehicle operation safety and ensuring quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

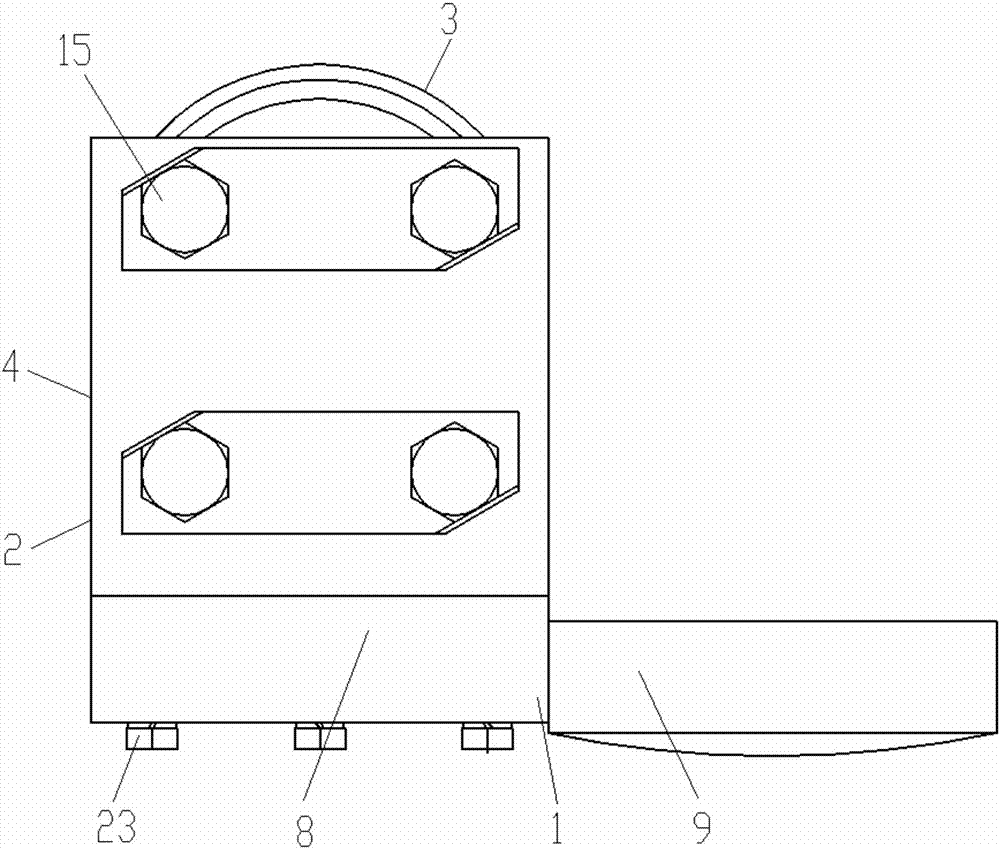

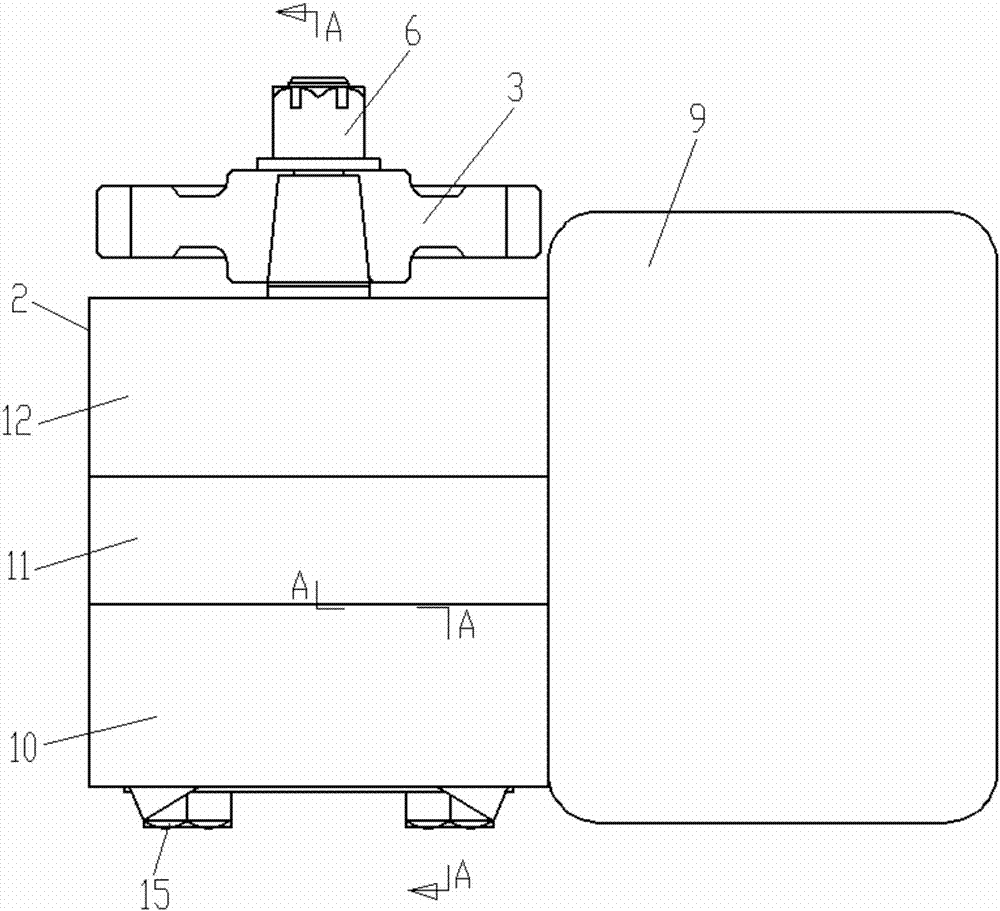

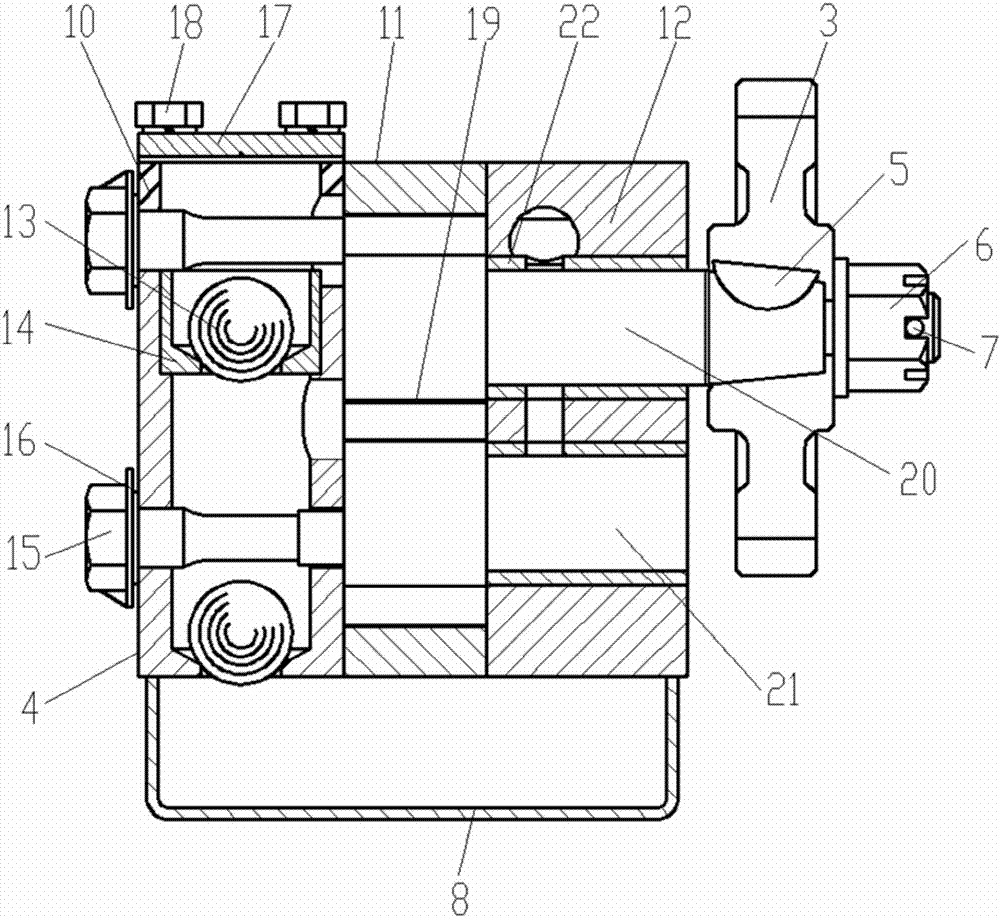

[0016] Attached below Figure 1-3 Embodiments of the present invention are described.

[0017] Gearbox lubrication pumps for rail vehicles such as figure 1 and 2 As shown, there are suction filter 1, oil pump 2 and oil pump gear 3, such as figure 2 As shown, the oil pump 2 includes an oil pump casing 4, and the oil pump casing 4 includes a ball valve chamber 10, a pump body 11 and a gear box 12, and the ball valve chamber 10 and the gear box 12 are respectively placed on both sides of the pump body 11 and Fixedly connected with it, the ball valve chamber 10, the gear box 12 and the pump body 11 are fixedly connected by the connecting piece III15 and locked by the stop washer 16; the pump body 11 is supported by the gear shaft I20 and the gear shaft II21 There is a gear pair 19, the gear pair 19 is fixed in the pump body 11 through the copper sleeve 22 on the gear shaft I20 and the gear shaft II21 in the gear box 12, and one end of the gear shaft I20 passes through the outs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com