Device and method of simulating complicated pile-loading action on soil surface

A kind of simulated soil, complex technology, applied in the direction of measuring device, using stable tension/pressure test material strength, instrument, etc., to achieve the effect of convenient disassembly and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

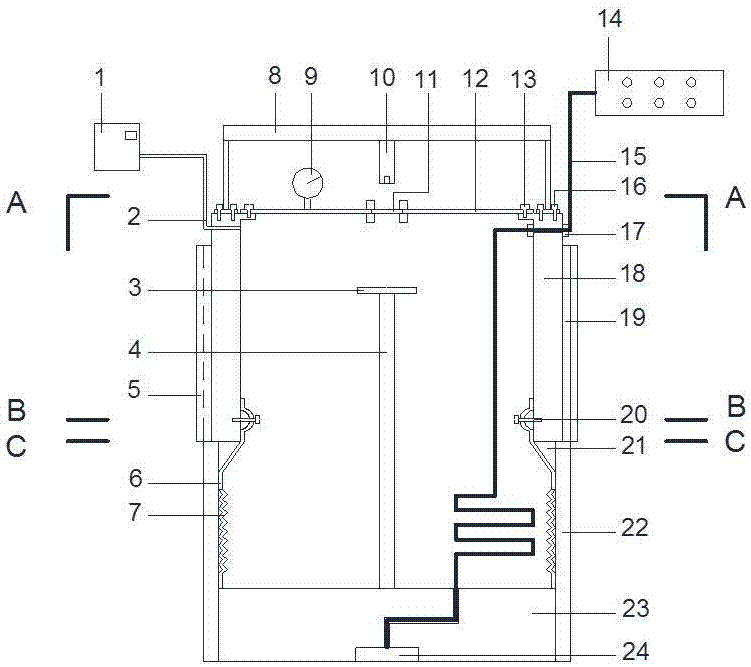

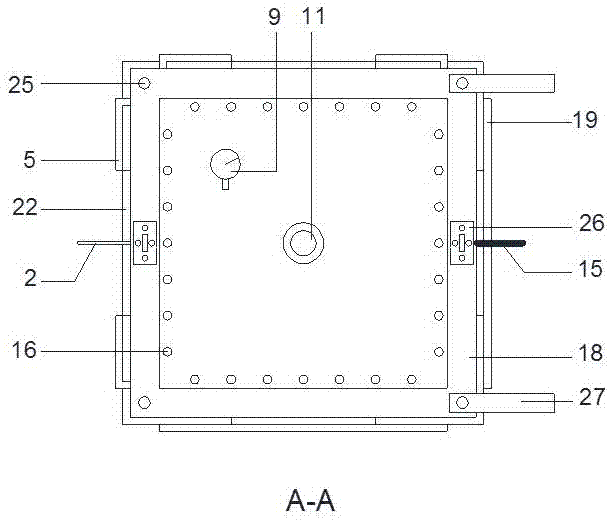

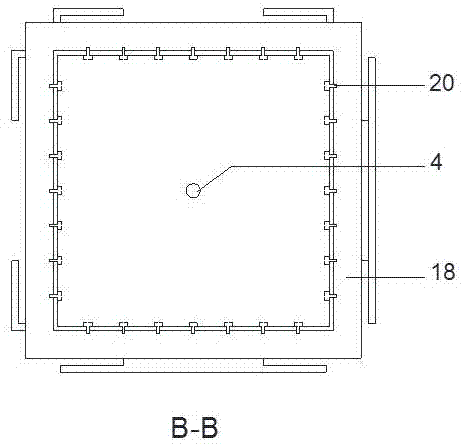

[0029] The components of the device for simulating the complex heaping action of the soil surface in this embodiment are as follows: figure 1 , figure 2 , image 3 and Figure 4 As shown, the assembly is in the shape of a rectangular barrel as a whole, and is composed of a top cover 12 , an upper section 18 , a lower section 22 and a bottom plate 23 . The component top cover 12 is a rectangular steel plate, connected to the top of the component upper section 18 by cover bolts 13 , and the top cover bolts 13 are equally spaced along the edge of the component top cover 12 . A pressure gauge 9 is installed on the top of the component top cover 12 for monitoring the air pressure inside the component. The middle part of the component top cover 12 is inlaid with high-strength optical glass 11 . The upper section 18 of the assembly is surrounded by steel plates to form a rectangle, and two concave arms 5 and two convex arms 19 are arranged on the outside respectively. The concav...

Embodiment 2

[0031] The device for simulating complex surcharge on the soil surface in the embodiment of the invention is used in conjunction with a model test box to simulate surcharges on the soil surface with large areas in the middle and small areas around. Such as Figure 5 and Figure 6As shown, the single components are interlocked and connected into an integral structure by the concave arm and the convex arm installed on the outer wall of the component to realize the predetermined function of the device of the present invention. The plane shape of the overall structure is determined according to the simulated soil surface surcharge plane distribution, and the fixed arm of the edge position component is fixed on the wall of the model test box to ensure the vertical stability of the overall structure.

[0032] Nine components are interlocked and connected to form an overall structure, and the outer component is fixed on the wall of the model test box through a fixed arm. The middle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com