Device and method for evaluating sand carrying capacity of carbon dioxide dry-process fracturing fluid

A technology for dry fracturing fluid and carbon dioxide, which is applied to the analysis of materials and instruments, can solve the problems of difficulty in obtaining effective experimental data and visual and quantitative evaluation of the sand-carrying performance of carbon dioxide dry fracturing fluid. The effect of simple structure and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

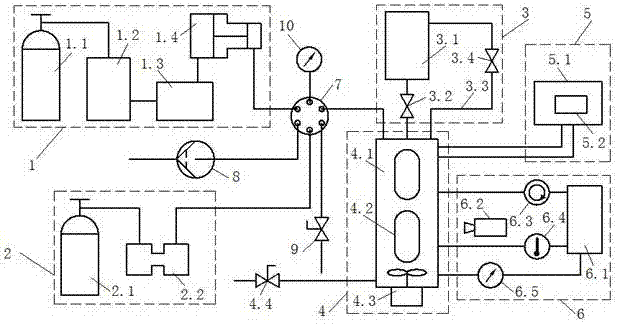

[0040] In order to overcome the problems existing in the existing carbon dioxide dry fracturing fluid performance evaluation experimental device that it is difficult to intuitively and quantitatively evaluate the sand-carrying performance of carbon dioxide dry fracturing fluid in a relatively large temperature and pressure range, and to obtain effective experimental data, this embodiment provided as figure 1 The sand-carrying performance evaluation device of carbon dioxide dry fracturing fluid is shown, including carbon dioxide booster system 1, viscosity raising agent injection system 2, proppant addition system 3, high-pressure visual stirring vessel 4, temperature control system 5 and data acquisition System 6;

[0041] The proppant addition system 3, temperature control system 5 and data acquisition system 6 are all connected to the high-pressure visualization stirring vessel 4, the proppant addition system 3 is installed on the top of the high-pressure visualization stirr...

Embodiment 2

[0044] On the basis of Example 1, the carbon dioxide pressurization system 1 includes a carbon dioxide gas cylinder 1.1, a cooler 1.2, a buffer container 1.3 and a booster pump 1.4 connected through pipelines in sequence, and the booster pump 1.4 is connected to the six-way through a pipeline valve 7. The carbon dioxide in the carbon dioxide storage bottle 1.1 is cooled by the cooler 1.2, and then enters the buffer container 1.3 to obtain liquid carbon dioxide, which is pressurized by the booster pump 1.4 and then enters the high-pressure visualization stirring container 4.

Embodiment 3

[0046] On the basis of Example 1, the viscosity-raising agent injection system 2 includes a viscosity-raising agent storage tank 2.1 and a high-pressure metering pump 2.2. The viscosity-raising agent storage tank 2.1 is connected to the inlet of the high-pressure metering pump 2.2 through a pipeline, and the high-pressure metering pump 2.2 The outlet of is connected to the six-way valve 7 through a pipeline. The viscosity raising agent in the viscosity raising agent storage tank 2.1 is metered by the high pressure metering pump 2.2 and then enters the high pressure visualization stirring container 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com