Partially browned brown yogurt and its preparation process

A preparation process and a technology for browning, which are applied in the field of partially browned brown yogurt and its preparation, can solve the problems of different stabilizer formulations, different raw materials, large nutrient loss, etc., and achieve good tissue state, reduced selection requirements, and thick taste. delicate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

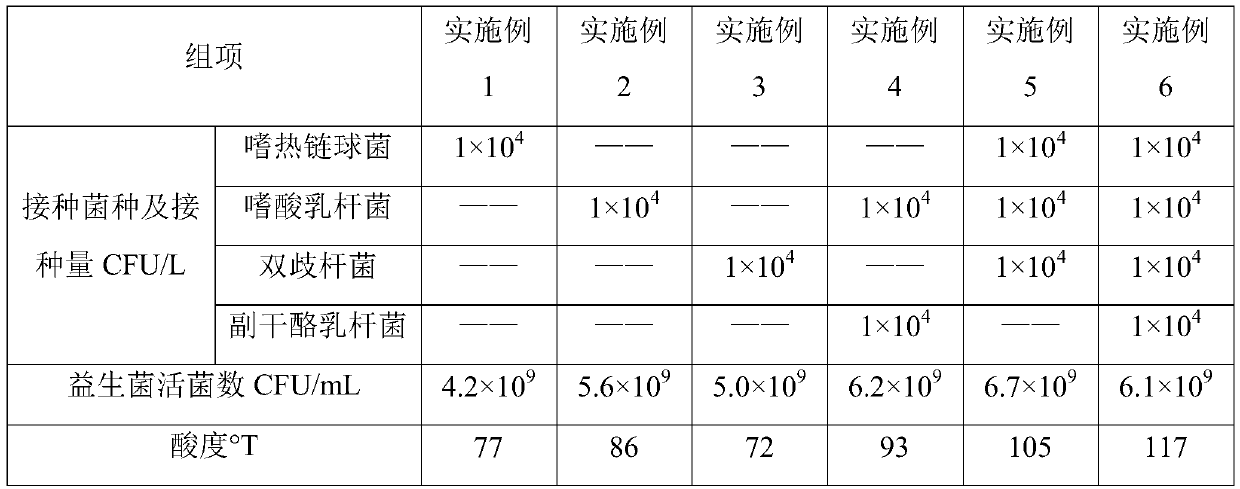

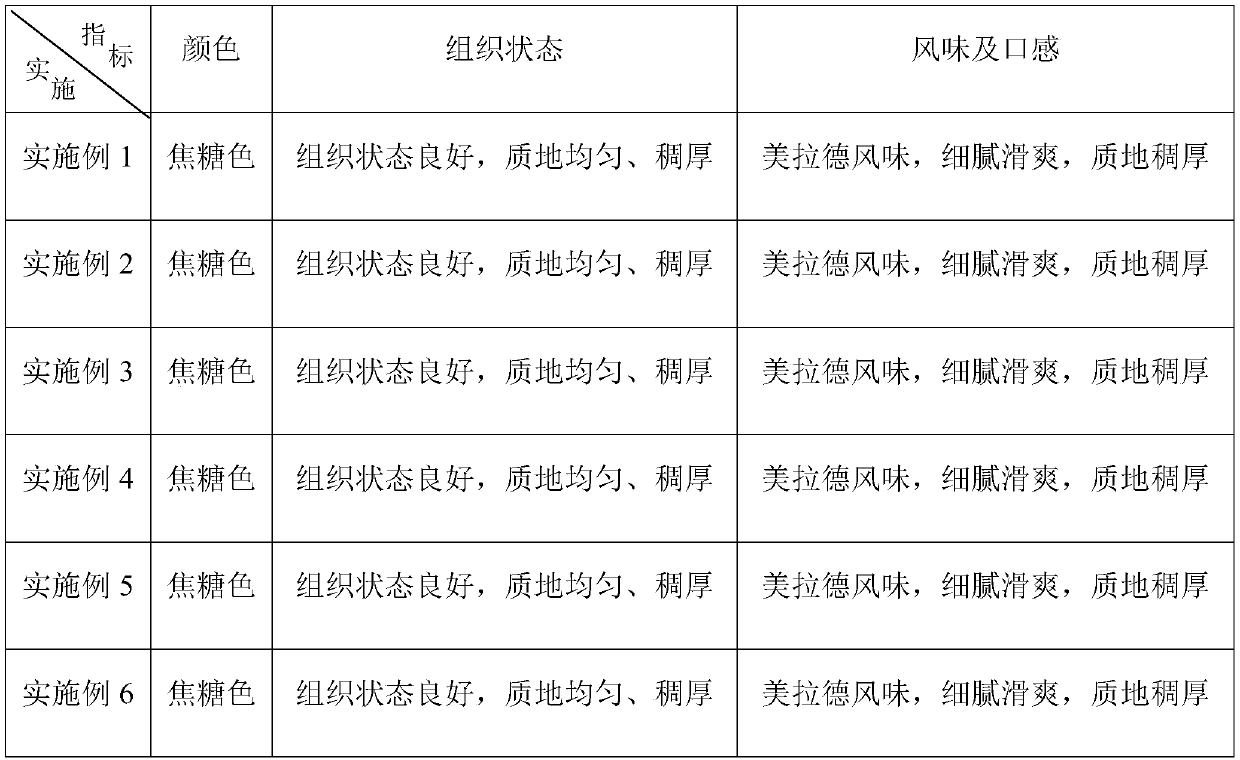

Examples

Embodiment 1

[0026] The preparation process steps of partial browning brown yoghurt are as follows:

[0027] (1) Pretreatment: Preheat the milk at 50-60°C, homogenize it under a pressure of 15-20MPa, and sterilize it at 90-95°C for 5-10 minutes after homogenization;

[0028] (2) Centrifugal separation: Centrifugal skim the pretreated milk, divide it into two parts, partly skimmed milk and cream, with a centrifugal speed of 2500-3000rpm, and separate 800±100L of raw milk per hour;

[0029] (3) Separation by ceramic membrane: using a ceramic membrane with a pore size of 0.3 μm to separate partially skimmed milk at low temperature into whey protein liquid and casein;

[0030] (4) Browning: Add glucose to the whey protein liquid, and can add whey powder as required to adjust the protein content, so that the protein content in the whey protein liquid is 4wt%, and then the whey protein-glucose solution is heated at 97 ° C Carry out insulation browning, the reaction time is 2.5h;

[0031] (5) M...

Embodiment 2

[0035] The preparation process steps of partial browning brown yoghurt are as follows:

[0036] (1) Pretreatment: Preheat the milk at 50-60°C, homogenize it under a pressure of 15-20MPa, and sterilize it at 90-95°C for 5-10 minutes after homogenization;

[0037] (2) Centrifugal separation: Centrifugal skim the pretreated milk, divide it into two parts, partly skimmed milk and cream, with a centrifugal speed of 2500-3000rpm, and separate 800±100L of raw milk per hour;

[0038] (3) Separation by ceramic membrane: using a ceramic membrane with a pore size of 0.3 μm to separate partially skimmed milk at low temperature into whey protein liquid and casein;

[0039] (4) Browning: Add glucose to the whey protein liquid, and can add whey powder as required to adjust the protein content, so that the protein content in the whey protein liquid is 4wt%, and then the whey protein-glucose solution is heated at 97 ° C Carry out insulation browning, the reaction time is 2.5h;

[0040] (5) M...

Embodiment 3

[0044] The preparation process steps of partial browning brown yoghurt are as follows:

[0045] (1) Pretreatment: Preheat the milk at 50-60°C, homogenize it under a pressure of 15-20MPa, and then sterilize it with heat preservation at 90-95°C for 5-10 minutes after homogenization;

[0046] (2) Centrifugal separation: Centrifugal skim the pretreated milk, divide it into two parts, partly skimmed milk and cream, with a centrifugal speed of 2500-3000rpm, and separate 800±100L of raw milk per hour;

[0047] (3) Separation by ceramic membrane: using a ceramic membrane with a pore size of 0.3 μm to separate partially skimmed milk at low temperature into whey protein liquid and casein;

[0048](4) Browning: Add glucose to the whey protein liquid, and can add whey powder as required to adjust the protein content, so that the protein content in the whey protein liquid is 4wt%, and then the whey protein-glucose solution is heated at 97 ° C Carry out insulation browning, the reaction ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com