Extrusion molded product having core material

A core material and product technology, applied in the field of extrusion molding products, can solve problems such as sliding and easy drop of the main body of molded products, and achieve the effect of maintaining sealing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

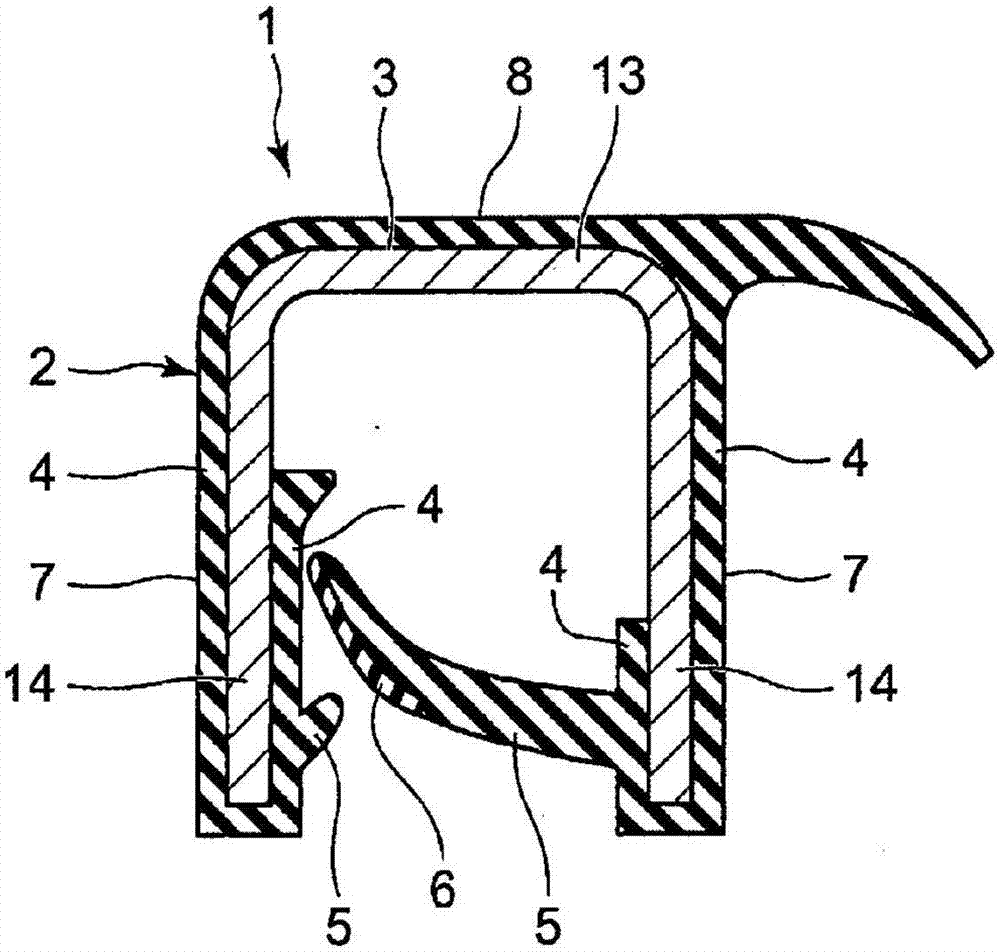

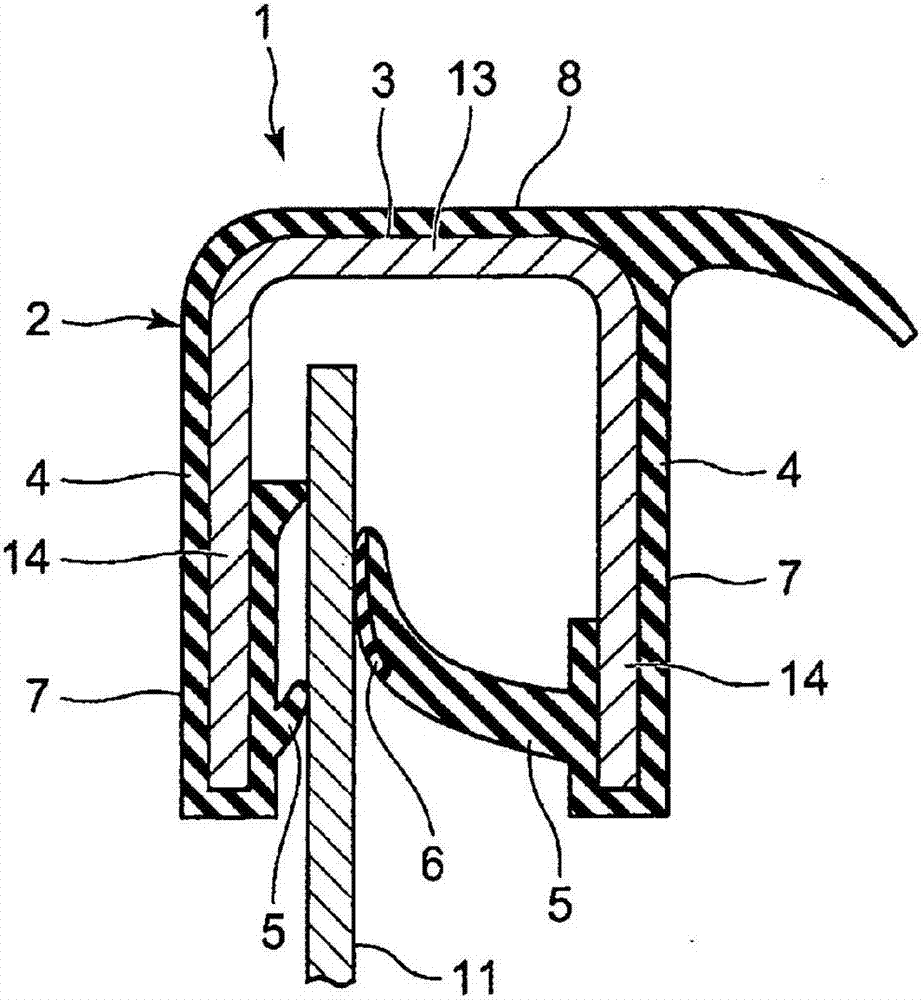

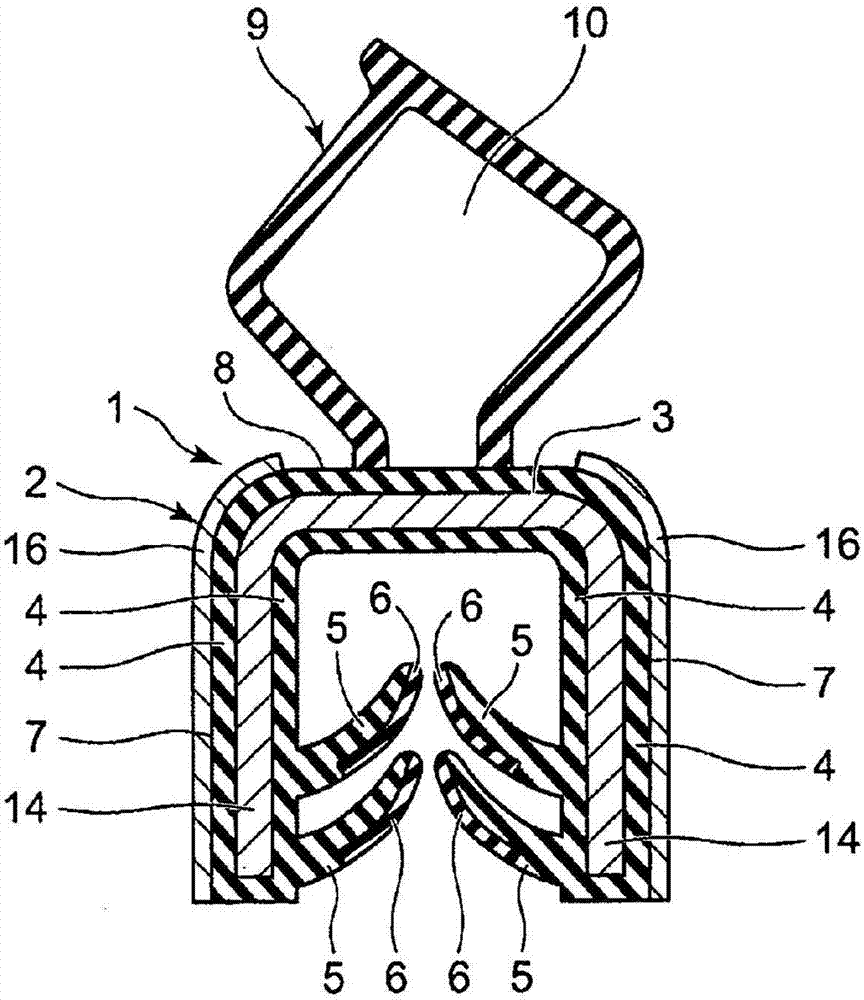

[0028] Preferred embodiments of the extrusion molded product of the present invention are described below with reference to the accompanying drawings. The embodiments described below are merely examples of the present invention, and thus the present invention can be realized in all kinds of modifications within the technical idea of the present invention, and it is by no means intended to limit the present invention to these embodiments.

[0029] will be described on the basis of the accompanying drawings showing embodiments of the present invention, and figure 1 A cross-sectional view is shown of an extrusion molded product having a core for mounting on a flange around openings in the body of a motor vehicle, such as doors, trunks, and rear door perimeters. A molded product body (1) is formed by extruding a core material (3) of synthetic resin or metal and a coating element (4) of thermoplastic elastomer into a grip portion (2) of generally U-shaped section. In this aspec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com