Connecting mechanism for pickling pools

A connection mechanism and pickling tank technology, which is applied in the field of auxiliary equipment for pickling of metal parts, can solve the problems of affecting the concentration, affecting the pickling effect, and affecting the cleanliness of the workpiece, so as to improve the cleanliness and reduce the defective rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings. It should be noted here that the descriptions of these embodiments are used to help understand the present invention, but are not intended to limit the present invention. In addition, the technical features involved in the various embodiments of the present invention described below may be combined with each other as long as they do not constitute a conflict with each other.

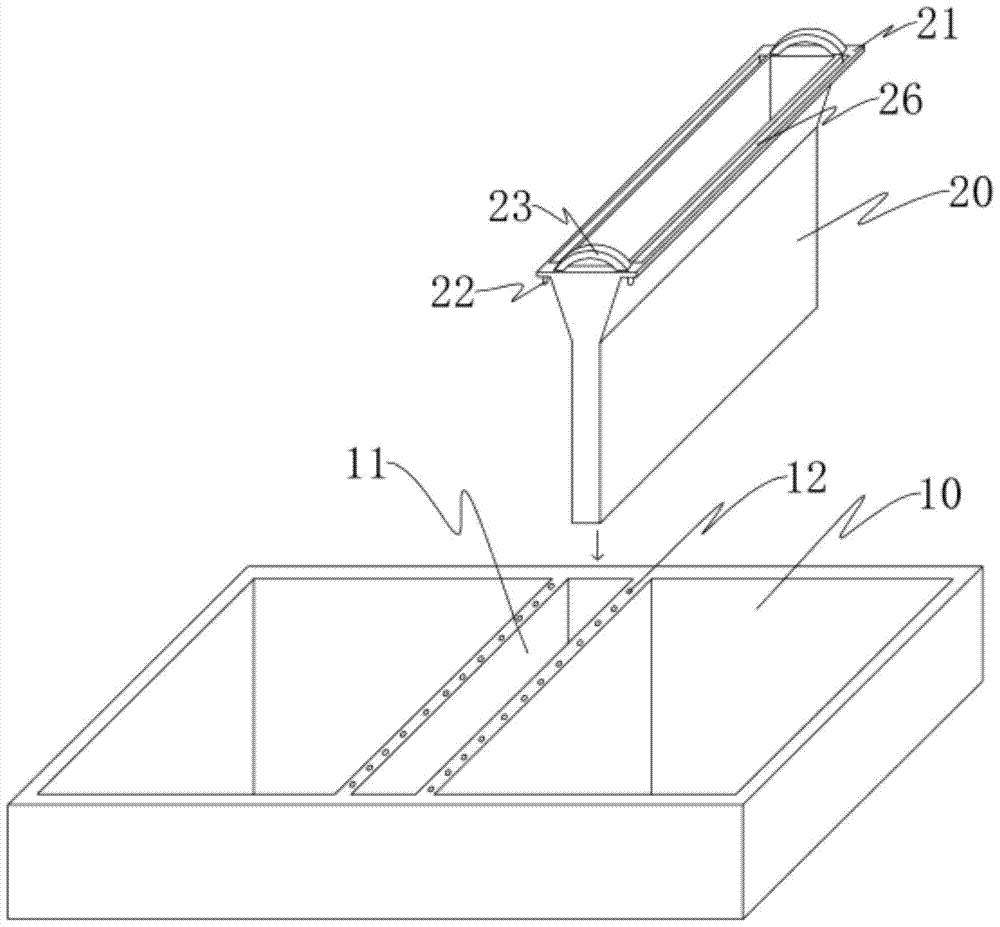

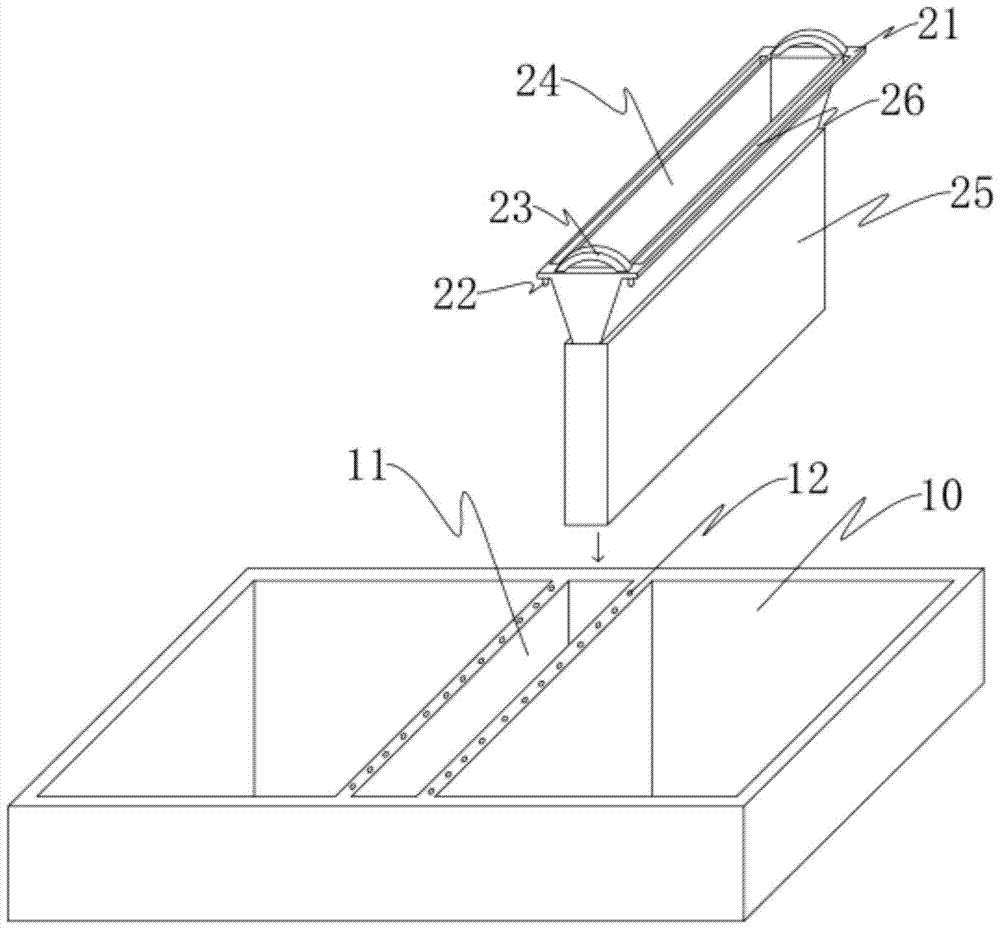

[0019] exist figure 1 Shown is a structural schematic diagram of Embodiment 1 of a pickling pool connection mechanism of the present invention, the mechanism is installed between two adjacent pickling pools 10, and the upper end surface of the adjacent wall of the pickling pool 10 is provided with a concave Groove 11; the main body of the mechanism is an open box body 20 inserted into the above-mentioned groove; the upper end of the box body 20 extends a boss 21 that is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com