A process for making color filter

A technology of color filter and manufacturing method, which is applied in the direction of photographic plate-making process, optics, optical components, etc. on the patterned surface, and can solve the problems of vivid color reproduction and analysis difficulties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] Some embodiments of the present invention are described in detail as follows. However, the invention may also be practiced broadly in other embodiments than those described in detail, and the scope of the invention should not be limited except by the appended claims.

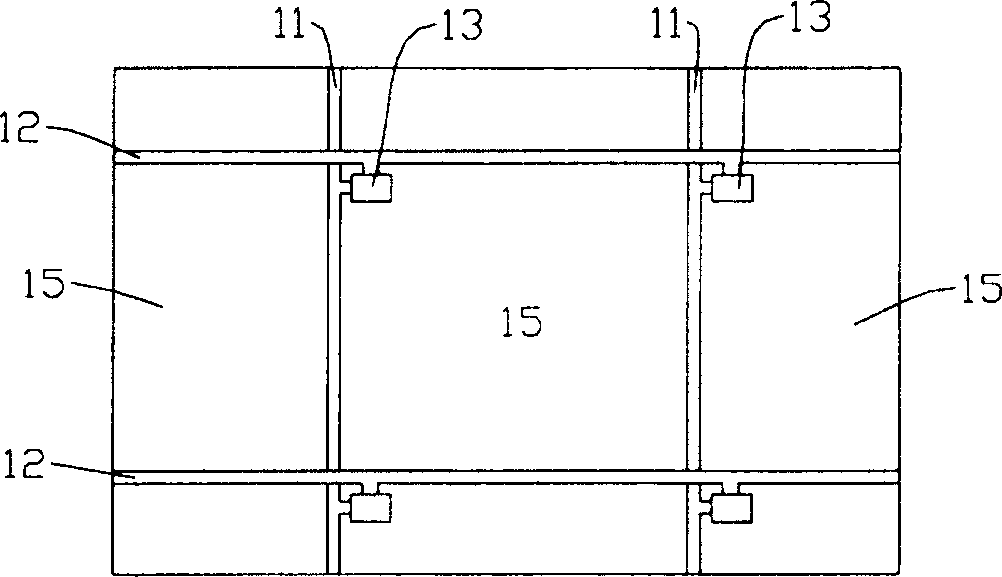

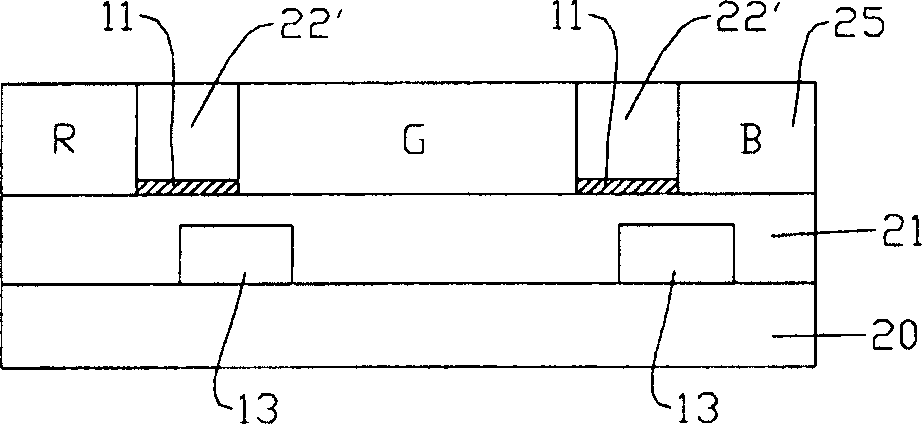

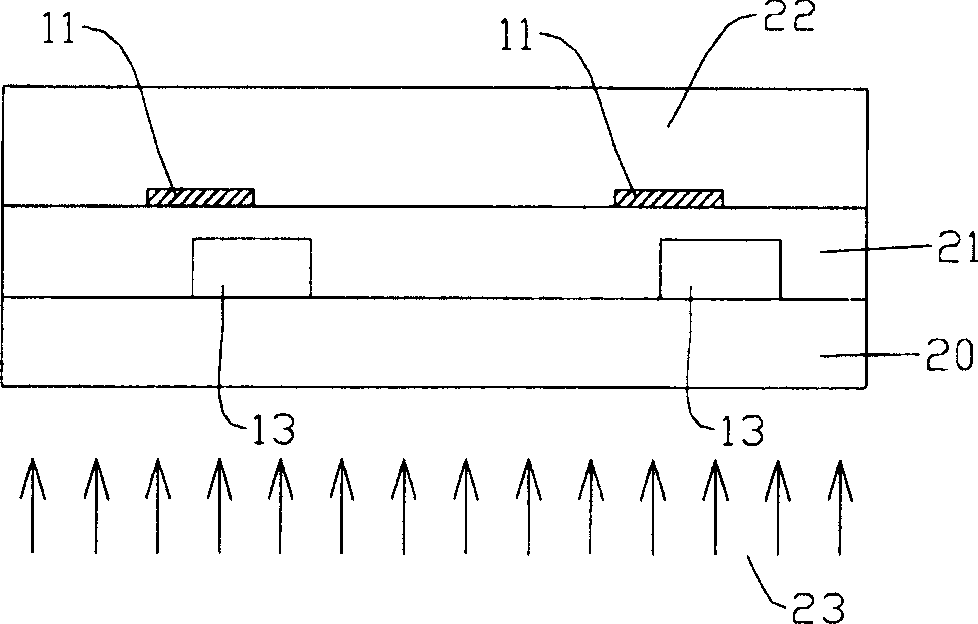

[0051] For a first embodiment of the present invention see figure 1 Plan view of color liquid crystal display and figure 2 A cross-sectional view of a color liquid crystal display. Figure 3A, B is a schematic diagram of the process. In this embodiment, the surface of the glass substrate on which components such as scanning lines and signal lines are arranged is called the front side, and the other side on which the above-mentioned components are not arranged is called the back side. First, a thin film transistor 13 (TFT: Thin Film Transistor) is formed on the glass substrate 20 , and the thin film transistor 13 can be manufactured by using a common semiconductor process method. Next, form an interla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com