Detecting and controlling method in ammeter production process

A technology of production process and control method, applied in the direction of computer control, general control system, control/regulation system, etc., to achieve good economic benefits, less false detection, and friendly control environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

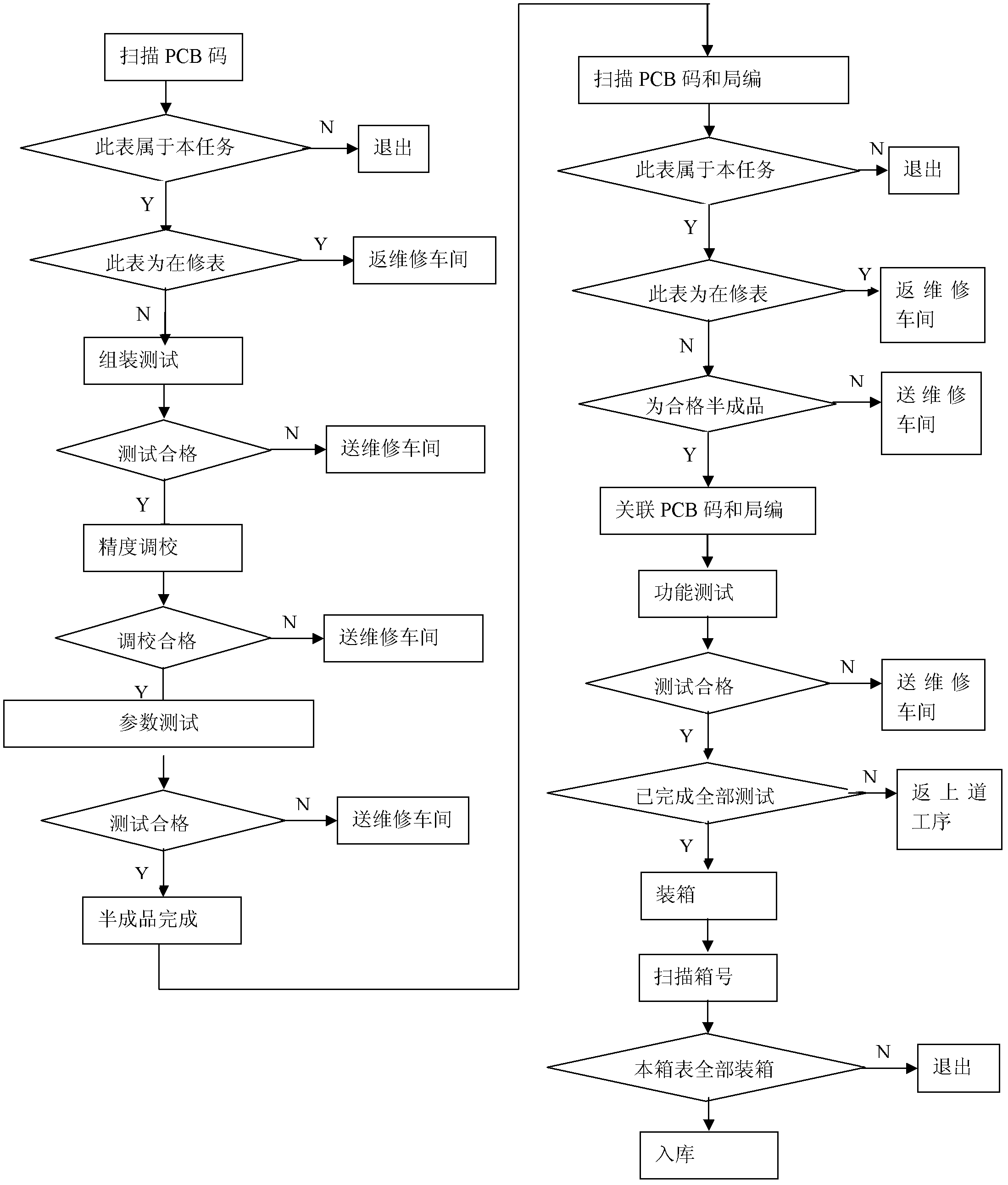

[0015] This embodiment is carried out in the control system that contains electronic computer and its scanner, and each technological step is finished in corresponding production workshop; The production of ammeter is divided into two technological processes of semi-finished product production and finished product production; Workshop; the system divides the order into assembly tasks and packaging tasks for production, the finished product of the assembly task is a semi-finished product, and the finished product of the packaging task is a finished product; the assembly task is assigned a set of barcode numbers according to the task quantity, and the control system controls the order according to this barcode , paste this barcode on the PCB in the assembly workshop, and then scan this barcode every time you test, if the barcode belongs to the number segment specified in this task, you are allowed to operate, otherwise you are not allowed to operate; after the test is completed, r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com