Vapor phase pressure and alcoholic strength variation on-line liquor taking process according to quality

A technology of gas phase pressure, quantity and quality wine picking, which is applied in the field of liquor picking, can solve the problems affecting the wine yield and wine quality, and achieve the effects of ensuring the quality of wine products, reducing human errors, and improving the degree of automatic operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The substantive content of the present invention will be further described in detail below in conjunction with specific embodiments.

[0042] Example 1

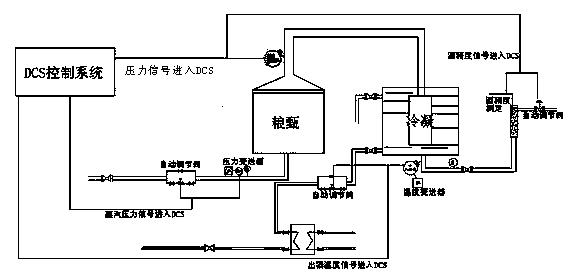

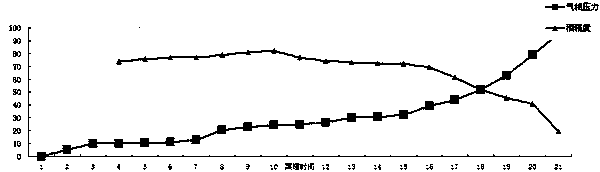

[0043] The gas phase pressure and alcohol content change online quantity and quality wine picking process is characterized in that the gas phase of the steamed wine is monitored online through the pressure transmitter above the outlet of the grain screen and the alcohol content online detector installed on the wine outlet pipeline. Pressure and alcohol content, the gas phase pressure data and the monitored alcohol content data are transmitted to the DCS control system in real time, and the DCS control system compares the real-time gas phase pressure data and alcohol content data with the preset pressure data and alcohol content data Judgment, when the gas phase pressure and alcohol content data are equal to the preset pressure and alcohol content data respectively, the DCS control system controls the automatic opening ...

Embodiment 2

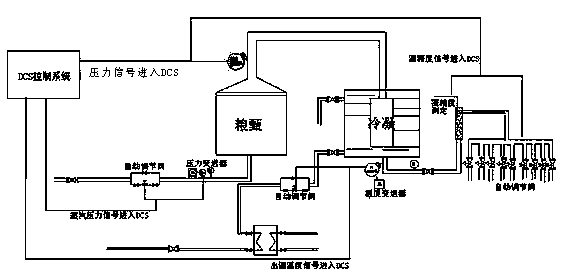

[0051] Basically the same as embodiment 1 process step, on this basis:

[0052] Wine picking is carried out in four stages according to the vapor phase pressure of the steamed wine and the alcohol content of the wine body. There are four automatic regulating valves at the place where the wine is connected. The alcohol content is 73.0~74.0%VOL; the pressure of the second distillate section is 10.35~24.4KPa, the alcohol content of the second section wine is 74.1~82.0%VOL; the pressure of the third section section is 24.5~39KPa, the third section wine The alcohol content of the wine is 81.9~69.1%VOL; the pressure of the fourth distillate section is 39.1~100KPa, and the alcohol content of the fourth section wine is 69.0~6.0%VOL.

[0053] The pressure transmitter is set at 80cm above the outlet of the grain screen cover.

[0054] The steam pressure required for steaming wine is: 0.03Mpa.

[0055] The wine flow temperature during picking is 30°C.

Embodiment 3

[0058] Basically the same as embodiment 1 process step, on this basis:

[0059] Picking wine is divided into nine sections according to the gas phase pressure of the steamed wine and the alcohol content of the wine body. There are nine automatic regulating valves at the wine receiving place, and the pressure of the first section of the steamed wine is 10.1-10.34KPa. alcohol content is 73.0~74.0%VOL; the pressure of the second distillate section is 10.35~12.9KPa, the alcohol content of the second section wine is 74.1~79.0%VOL; the pressure of the third section section is 13~24.4KPa, the third section wine The alcohol content of the wine is 79.1~82.0%VOL; the pressure of the fourth distillate section is 24.5~26KPa, the alcohol content of the fourth section wine is 81.9~74.0%VOL; the pressure of the fifth distillate section is 26.1~32.5KPa, the fifth section The alcohol content of the wine is 73.9~72.0%VOL; the pressure of the sixth distillate section is 32.6~39KPa, the alcohol c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com