Gas phase temperature and pressure changing online quality-based liquor making process

A technology of gas phase temperature and gas phase pressure, applied in the field of liquor picking, can solve problems such as errors, affecting wine yield and wine quality, and achieve the effects of improving yield, ensuring wine quality, and removing impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

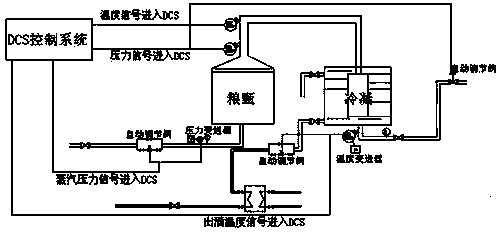

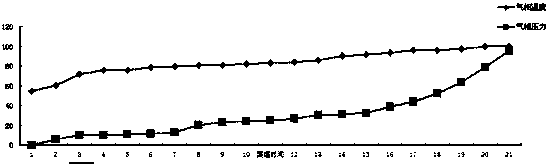

[0040] Gas phase temperature and gas phase pressure change online quantity and quality wine picking process, through the temperature transmitter and pressure transmitter above the outlet of the grain screening cover, online monitoring of the gas phase temperature and gas phase pressure of the steamed wine, and the data of the gas phase temperature and gas phase pressure , real-time transmission to the DCS control system, the DCS control system compares the real-time gas phase temperature and gas phase pressure data with the preset temperature and pressure data, and when the gas phase temperature and gas phase pressure data are equal to the preset temperature and pressure data respectively At this time, the DCS control system controls the automatic opening or closing of the automatic regulating valve at the wine receiving place to carry out the quantity and quality of the wine.

[0041] Picking wine is carried out in three stages according to the gas phase temperature and gas ph...

Embodiment 2

[0047] Basically the same as embodiment 1 process step, on this basis:

[0048] Wine picking is carried out in four sections according to the gas phase temperature and gas phase pressure of the steamed wine. There are four automatic regulating valves at the wine receiving place, and the temperature of the first distilled section of the steamed wine is 72-75°C and the pressure is 10.1-10.34 KPa ;The temperature of the second fraction section is 75.1-81.9°C and the pressure is 10.35-24.4 KPa; the temperature of the third fraction section is 82-93.4°C and the pressure is 24.5-39 KPa; the temperature of the fourth fraction section is 93.5-100°C , the pressure is 39.1 ~ 100 KPa;

[0049] The temperature transmitter is set at 80cm above the outlet of the grain screen cover.

[0050] The pressure transmitter is set at 30cm above the outlet of the grain screen cover.

[0051] The steam pressure required for steaming wine is: 0.03Mpa.

[0052] The wine flow temperature during pickin...

Embodiment 3

[0054] Basically the same as embodiment 1 process step, on this basis:

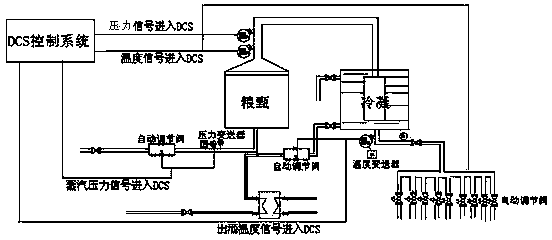

[0055] Wine picking is carried out in nine stages according to the gas phase temperature and gas phase pressure of the steamed wine, see figure 2 , there are nine automatic regulating valves at the place where the wine is connected, and the temperature of the first distillate section of distilled wine is 72-75°C and the pressure is 10.1-10.34 KPa; the temperature of the second distillate section is 75.1-80.5°C and the pressure is 10.35~12.9KPa; the temperature of the third fraction is 80.6~81.9℃, the pressure is 13~24.4KPa; the temperature of the fourth fraction is 82~83.5℃, the pressure is 24.5~26KPa; the temperature of the fifth fraction is 83.6 ~91.5℃, pressure 26.1~32.5KPa; temperature of the sixth fraction is 91.6~93.4℃, pressure 32.6~39KPa; temperature of the seventh fraction is 93.5~96℃, pressure 39.1~52KPa; eighth fraction The temperature of the section is 96.1-99.4°C and the pressure is 52.1-78...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com