Double-die-head compound interlaced two-component spunbond spunlace non-woven fabric production equipment and production process

A technology of spunbond spunlace and production equipment, which is applied in the direction of stretch spinning, non-woven fabrics, textiles and papermaking, etc., can solve the problems of uniformity deviation, affecting the market application of products, and inability to prepare leather base fabrics and filter materials. , to achieve the effect of solving the problem of strong lifting and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

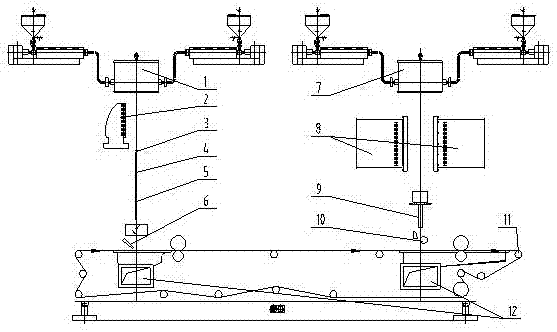

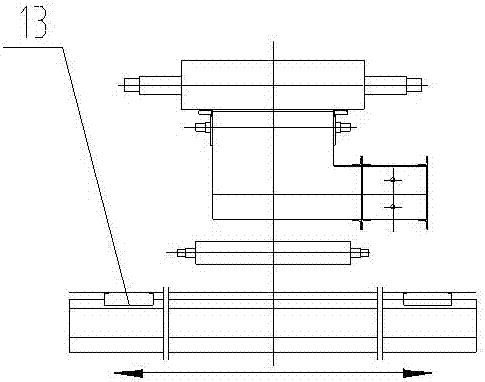

[0021] As shown in the figure, the double-die composite interlacing two-component spunbonded spunlace nonwoven production equipment of the present invention includes a web-laying machine 11, on which there are a tubular stretching mechanism and a long slit stretching mechanism; From top to bottom, the type drawing mechanism includes a composite die head for melt spinning small components, a one-way side blowing device 2, a drafting head 3, a stainless steel drafting tube 4, a spinning machine 5, and a guide device 6; the long slit The stretching structure includes, from top to bottom, a composite die head 7 of a melt spinning large component, a bidirectional side blowing device 8, and a long slit negative pressure stretching device 9. A hot air interference device 10 and a double-channel air suction mechanism 12 are provided on the web-laying machine, and the web-layin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com