Solar vacuum flat plate collector

A flat plate collector and solar energy technology, applied in the field of solar energy applications, can solve the problems of restricting the maximum heat collection temperature of the collector, limiting the use of the flat plate collector, etc., to achieve the effect of expanding the use and stabilizing industrial energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

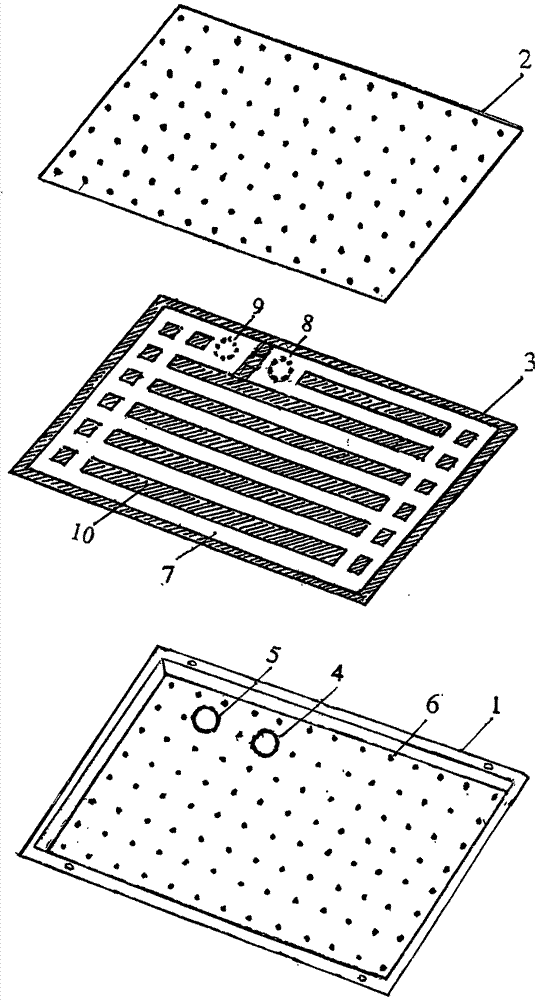

[0013] The specific embodiment of the present invention is described below in conjunction with accompanying drawing, solar vacuum flat plate heat collector comprises insulation box and heat-absorbing plate core, and heat-absorbing plate core 3 is arranged in the middle of heat-insulating box; Described heat-retaining box comprises box body 1 and lid 2 , the box body 1 and the box cover 2 are all made of glass; the bottom surface of the box body 1 has a number of point-like protrusions 6 with equal spacing along the horizontal direction, these point-like protrusions become the support columns of the vacuum space, and the bottom surface of the box body 1 also has inlet pipes. Hole 4 and pipe outlet hole 5; Lid 2 is a piece of low-iron ultra-clear flat glass, and its lower surface also has the same point-like protrusion 6 as the bottom surface of box body 1; Described heat-absorbing plate core 3 is made of metal material Production, the heat-absorbing plate core 3 is a heat-absorb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com