Novel steel tube weld strength detection device

A welding seam strength and detection device technology, which is applied in the direction of measuring devices, using sound waves/ultrasonic waves/infrasonic waves to analyze solids, and using sound waves/ultrasonic waves/infrasonic waves for material analysis, etc. It can solve the problems of low detection efficiency, difficulty in automation, and complex operation processes, etc. problem, to achieve the effect of high detection efficiency and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

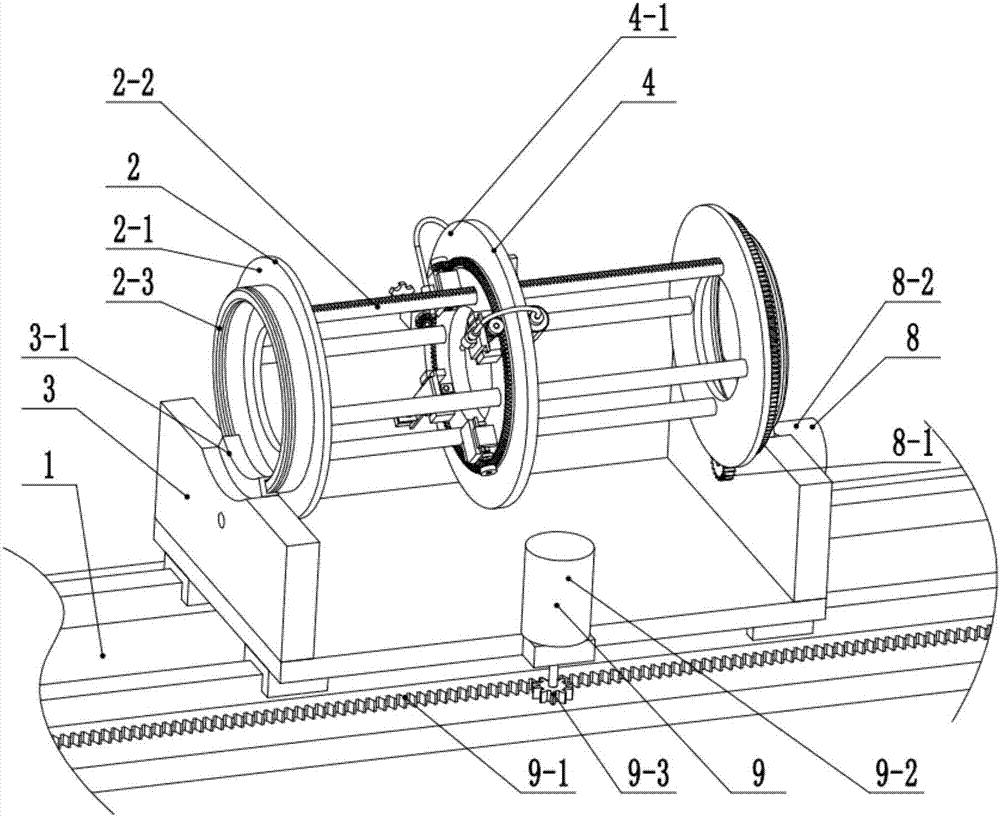

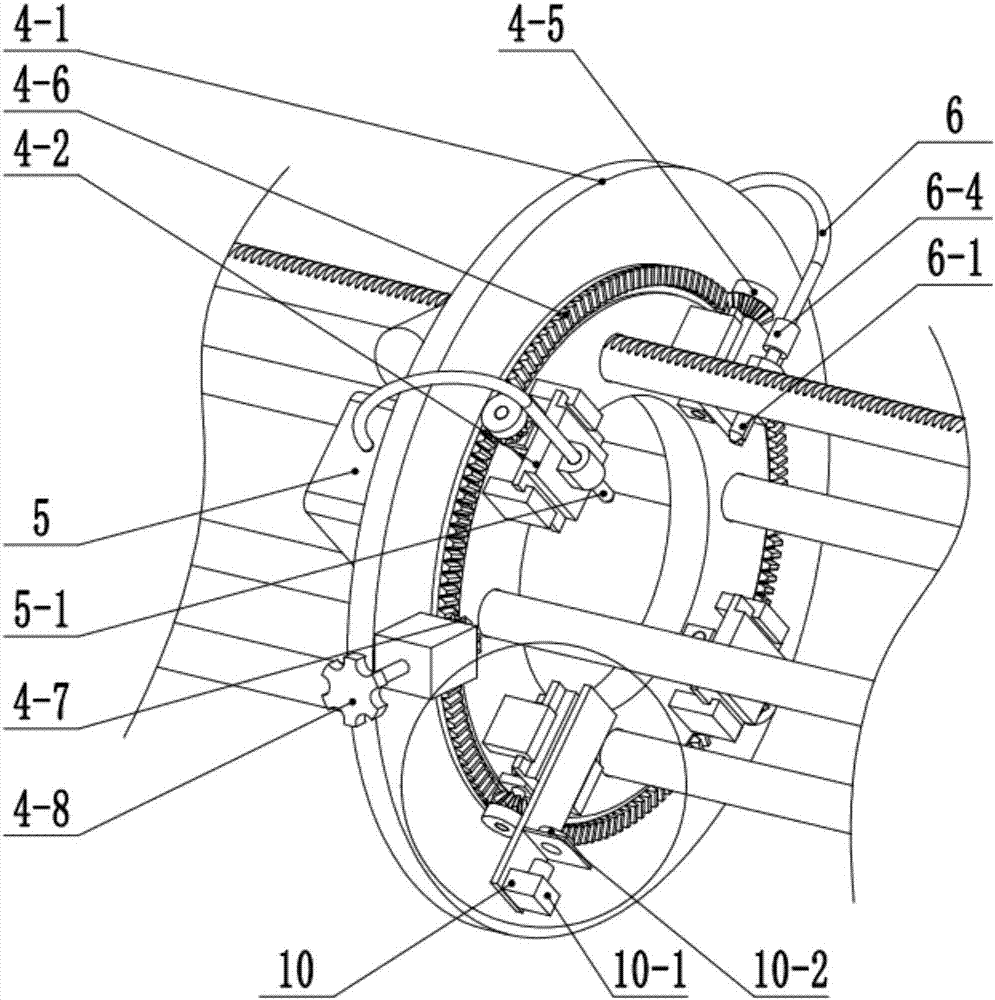

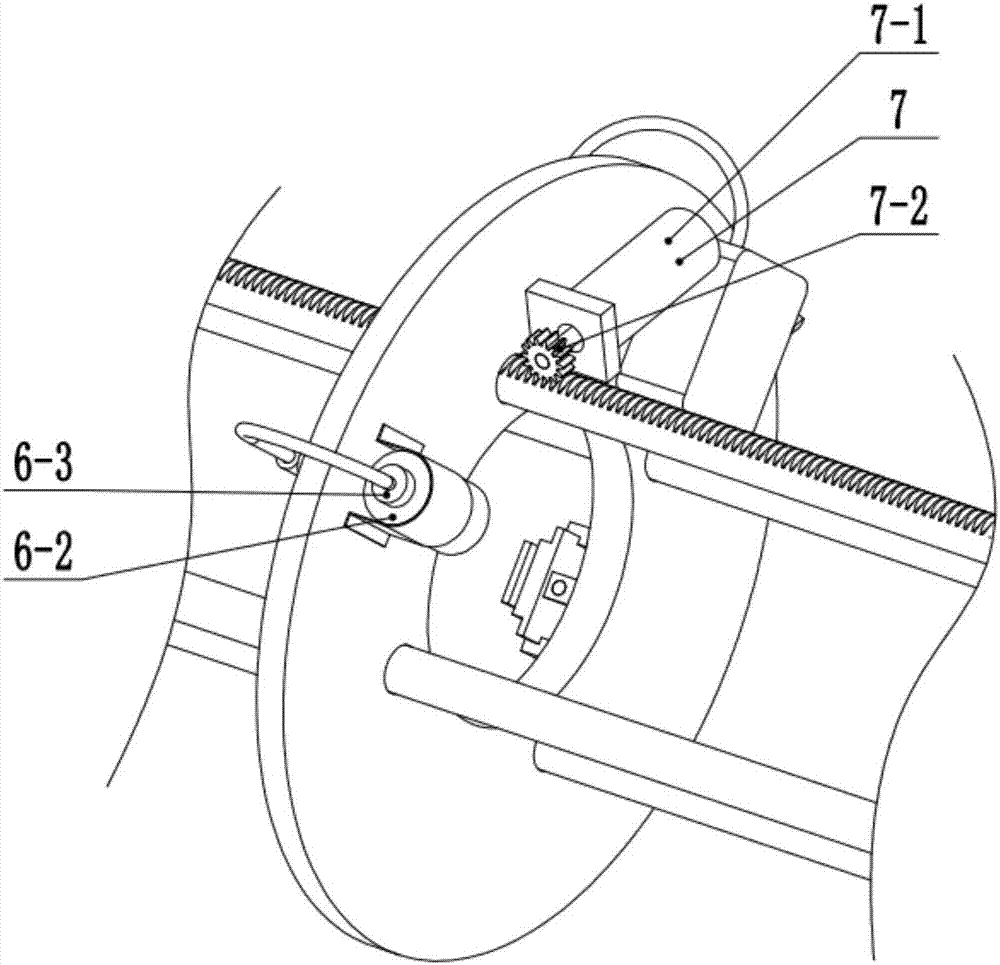

[0021] as attached figure 1 to attach image 3 A new type of steel pipe weld strength detection device shown includes a frame 1, a turret 2 and a turret support 3, the turret 2 is rotatably mounted on the turret support 3, and the The turret support 3 is installed on the frame 1, and the turret support 3 can be linearly translated relative to the frame 1; the turret 2 includes two concentrically installed annular end plates 2-1, two At least two guide rods 2-2 are arranged between two annular end plates 2-1, and a detection assembly 4 that can translate along its axial direction is provided on the guide rods 2-2, and the detection assembly 4 includes a ring-shaped The detection component seat 4-1 and the ultrasonic flaw detector 5 and the defect marking device 6 installed on the detection component seat 4-1, the flaw detection head 5-1 of the ultrasonic flaw detector...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap