A miniaturized non-radioactive electron source with controllable emission current

A current emission and radioactivity technology, applied in the field of miniaturized non-radioactive electron sources, can solve problems such as complex structure, small electron kinetic energy, and inability to change ionization parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

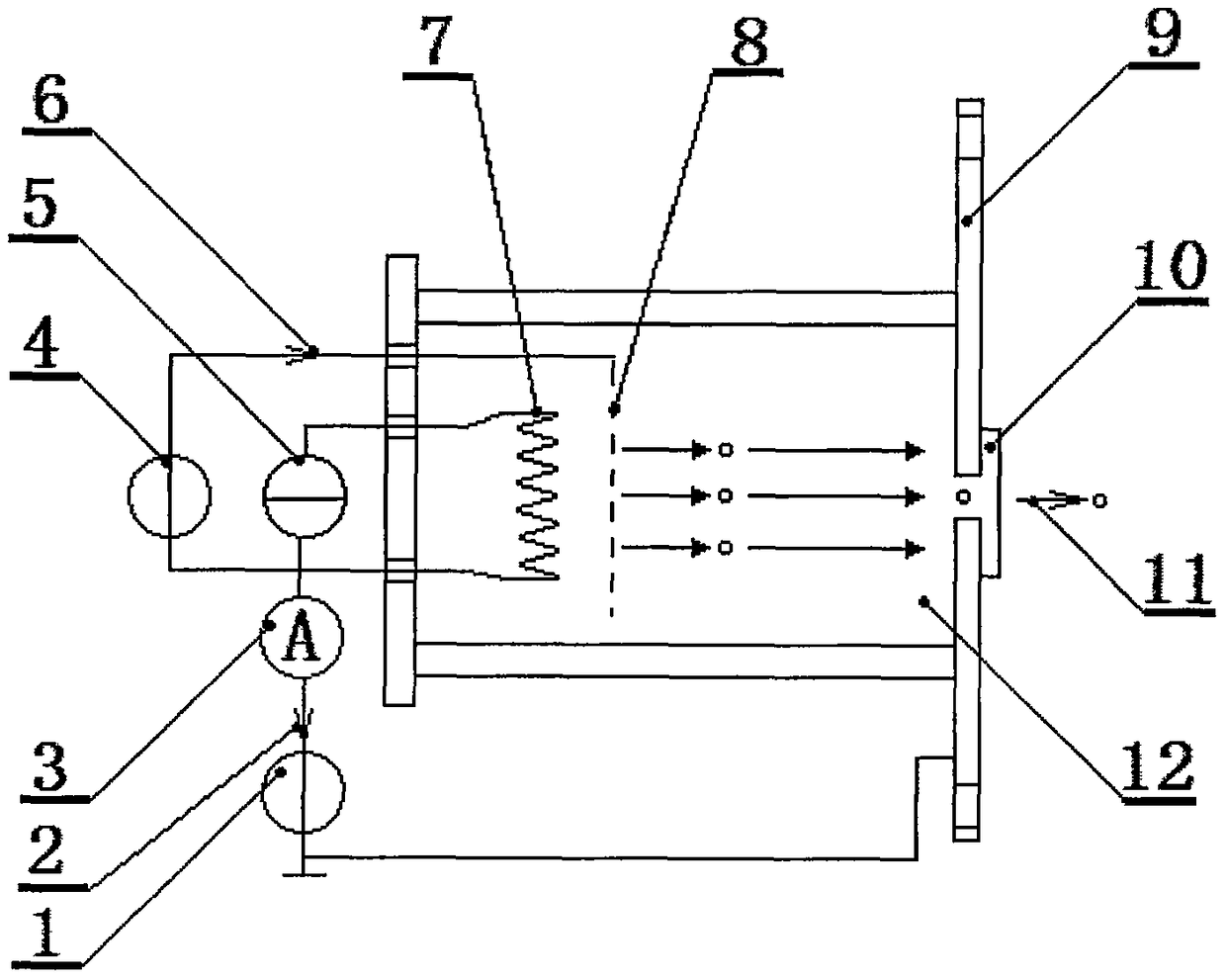

[0013] Such as figure 1 It is a schematic diagram of the present invention, including accelerating voltage source 1, electron emission current 2, ammeter 3, extracting voltage source 4, filament heating current source 5, extracting grid current 6, filament 7, extracting grid 8, accelerating electrode 9, nitriding Silicon film 10, electron current 11 in atmospheric environment, vacuum chamber 12, electron source works in pulse mode, described filament 7 is positioned at one end in vacuum chamber 12, and the other end of vacuum chamber 12 is described accelerating electrode 9, described accelerating There is an opening in the center of the electrode 9, and the silicon nitride film 10 is covered and closely attached to the central opening of the accelerating electrode 9 outside the vacuum chamber 12. Air will not pass through the silicon nitride film 10 and will not affect The vacuum environment in the vacuum chamber 12, the accelerating voltage source 1 generates a potential dif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com