Automatic feeding device for pig breeding

A technology of automatic feeding and driving motors, applied in animal feeding devices, applications, animal husbandry, etc., can solve the problems of high labor intensity, heavy workload, and low work efficiency, so as to reduce labor intensity and ensure feed fluidity , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

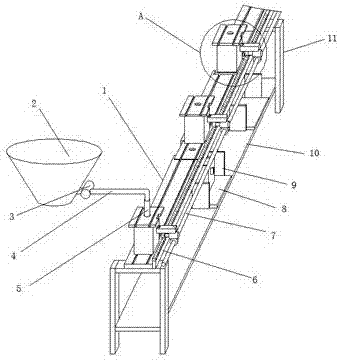

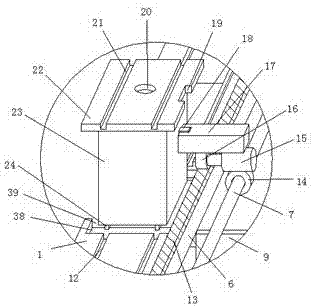

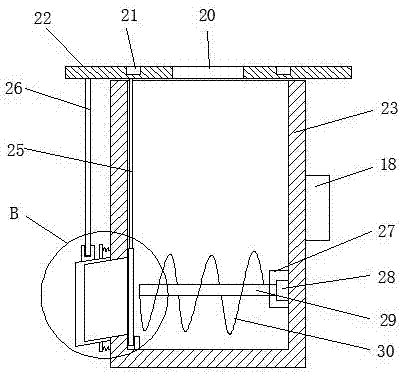

[0028] see Figure 1-4 , an automatic feeding device for pig breeding, comprising a bracket 11 and a mixing hopper 2, a guide plate 1 and a support plate 10 are fixedly connected to the bracket 11, and the guide plate 1 is located above the support plate 10, and a plurality of feeding plates are slidably connected on the guide plate 1 Case 23, a plurality of feeding boxes 23 bottom sides are fixedly connected with parallel slide bars 24, the guide plate 1 is provided with the first chute 12 corresponding to the slide bar 24, and the guide plate 1 is provided with a plurality of feed boxes 23 Corresponding box drop hole 39, the upper end cover of feeding box 23 is provided with box cover 22, and the box drop hole 39 place of guide plate 1 is provided with the limit retaining groove 38 corresponding with box cover 22, and box cover 22 upper side is offered with parallel. The second chute 21 of the second chute, and the second chute 21 corresponds to the slide bar 24, the first f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com