Method for manufacturing reinforcement cage with flange type reinforced stirrup

A manufacturing method and technology of steel cages, applied in the field of construction engineering, can solve problems such as low work efficiency, heavy workload, and great influence on welding quality and welding level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is further illustrated below by specific examples.

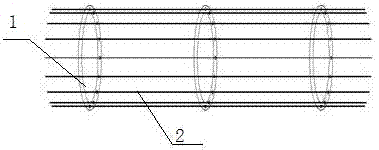

[0015] Such as figure 1 , figure 2 As shown, as shown, a method for making a steel cage with flanged strong stirrups, including

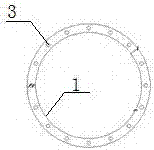

[0016] Step 1. According to the designed pile diameter, use a thick steel plate to make a ring plate 1 through a punching machine;

[0017] Step 2, on the plate body of the annular plate 1 described in step 1, carry out equally divided punching holes 3 according to the number and diameter of the main bars of the reinforcement cage to form reinforcing stirrups, and the diameter of the punching holes 3 is greater than the main bar diameter 5mm;

[0018] Step 3, making the reinforcement cage skeleton: the main reinforcement 2 spacing 2m of the reinforcement cage is provided with the order of a reinforcing stirrup to establish the reinforcement cage skeleton, wherein, the reinforcement cage and the main reinforcement 2 are fixed by welding;

[0019] Step 4, winding the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com