A sheet bonding and automatic output device

An automatic output and sheet material technology, which is applied in the direction of paper/cardboard layered products, chemical instruments and methods, lamination, etc. Material and other issues, to achieve the effect of automatic output and enhanced bonding firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

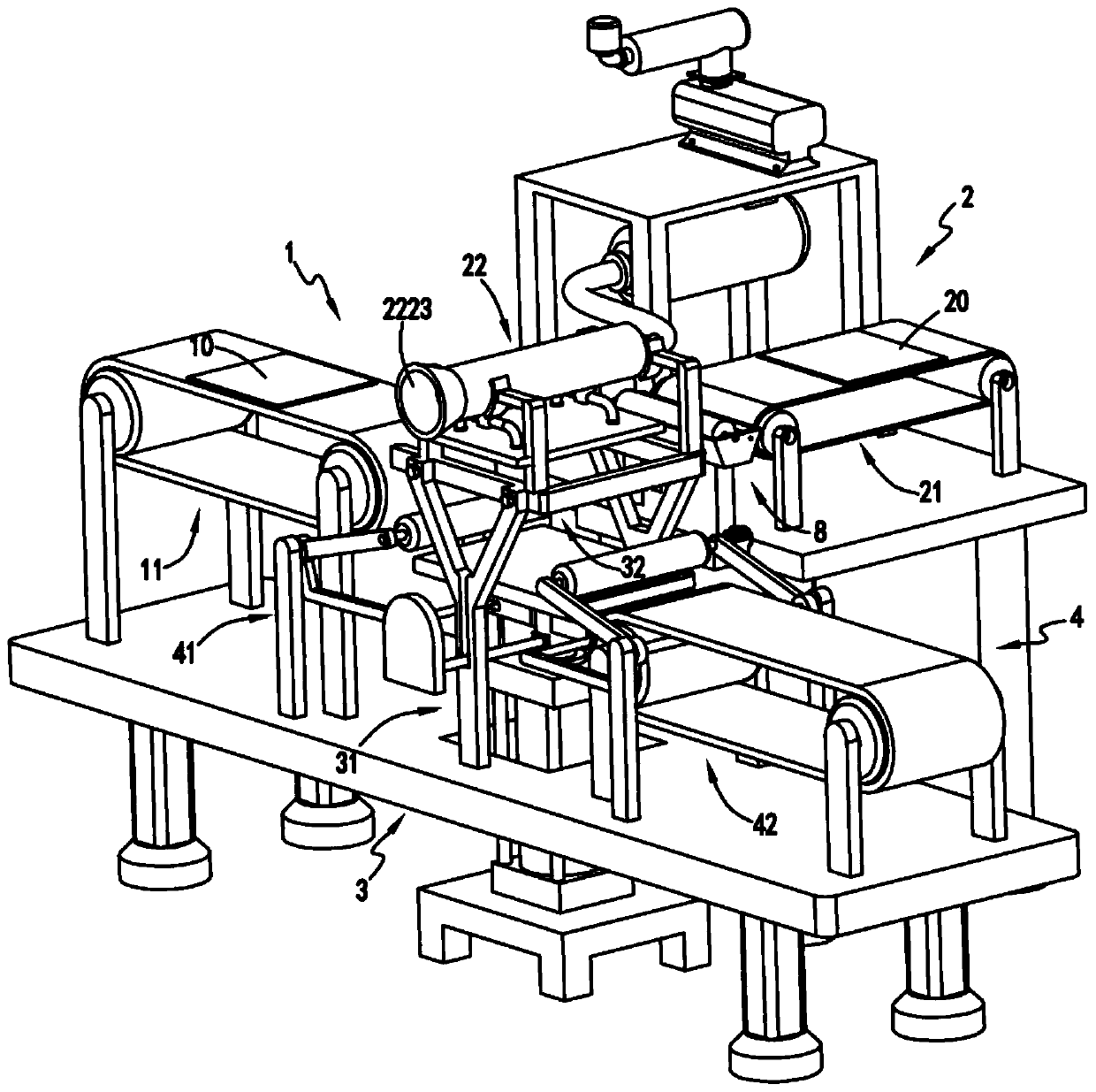

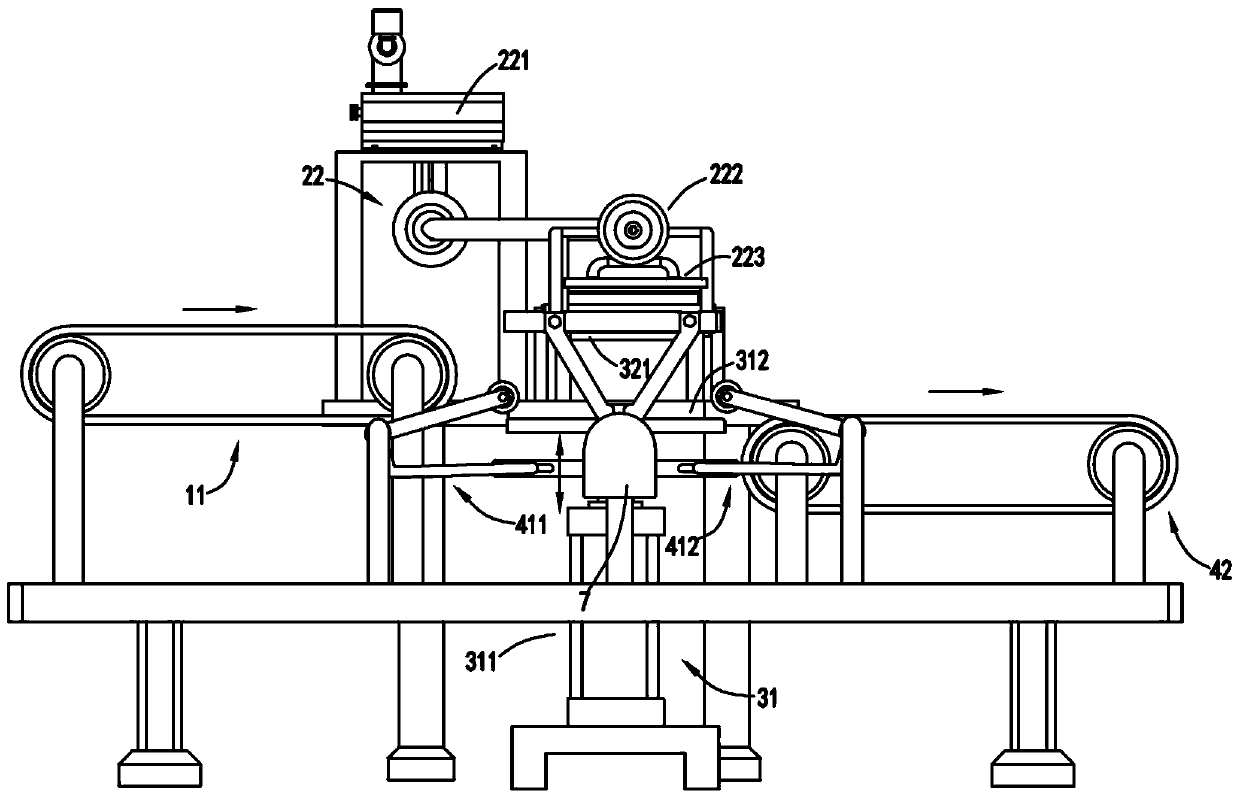

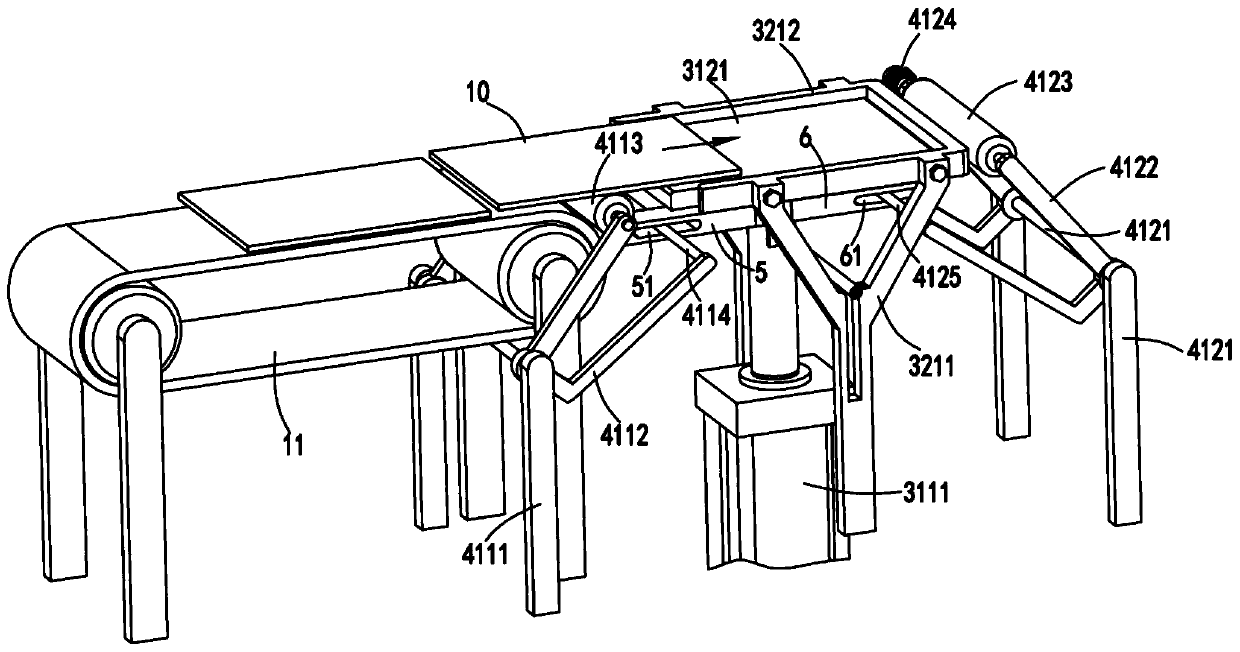

[0040] figure 1 It is a schematic diagram of the internal structure of the automatic output device after the plates are glued, figure 2 It is a schematic diagram of the front view of the automatic output equipment after the plates are glued, image 3 is a schematic diagram when the lower plate is transferred from the transfer mechanism a to the supporting device, Figure 4 It is a schematic diagram of the output of the composite board from the supporting device, Figure 5 It is a schematic diagram of the bonding of the lower plate and the upper plate, Figure 6 It is a schematic diagram of the structure when the support device moves to the output position after lamination, Figure 7 It is a schematic diagram of the structure of the conveying part of the upper plate, Figure 8 It is a cut-away schematic diagram of the negative pressure generating device and the negative pressure adsorption device, Figure 9 It is a schematic diagram when the pressing roller mechanism driv...

Embodiment 2

[0057] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 with Figure 9 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between the second embodiment and the first embodiment is that, as a preference, a baffle 7 is also included, and the baffle 7 is fixed on the telescopic rod of the lifting cylinder 3111 through the fixing rod 71, driven by the lifting cylinder 3111 Performing lifting motion, the baffle plate 7 is used to block the outlet 2223 of the negative pressure generating device 222 when the upper plate 20 and the lower plate 10 are glued together.

[0058] The setting of the baffle plate 7 makes the lower plate 10 and the upper plate 20 stick together, and the negative press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com