Biomass rotary propulsion pyrolysis device

A rotary device, biomass technology, applied in the direction of biofuel, spiral gasifier, indirect heating dry distillation, etc., can solve the problems of sealing leakage, high production and maintenance costs, and achieve a small pyrolysis tube, fast propulsion, good The effect of economic and environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the description of the drawings and the specific embodiments.

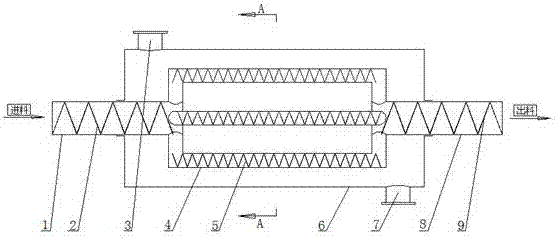

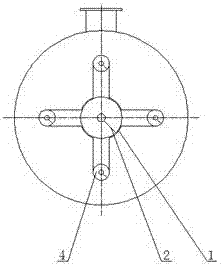

[0015] See Figure 1 to Figure 2 , A biomass rotating propulsion pyrolysis device, including a pyrolysis device; the pyrolysis device is connected with a gear or other rotating device, and the gear or other rotating device drives the pyrolysis device to rotate during operation. The pyrolysis device includes a feed pipe 1, a discharge pipe 8 and a number of pyrolysis pipes 4. The outlet of the feed pipe 1 is respectively connected and fixed with the inlets of a number of pyrolysis pipes 4. The outlet of the pyrolysis tube 4 is respectively connected with the inlet of the discharge tube 8; that is, the feeding tube 1, the discharge tube 8 and several pyrolysis tubes 4 are fixedly connected as a whole. The number here is one or more than one, and the number of pyrolysis tubes 4 can be selected according to actual needs, usually 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com