Monitoring system and method for consuming condition of target material in sputtering film forming device

A technology of a film forming device and a monitoring system, which is applied in the field of target material consumption monitoring system, can solve the problems such as failure to detect in time target material consumption, target material breakdown, backplane and product influence, etc., so as to avoid target material breakdown. Wear problems, improve the quality of finished products, and improve the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing.

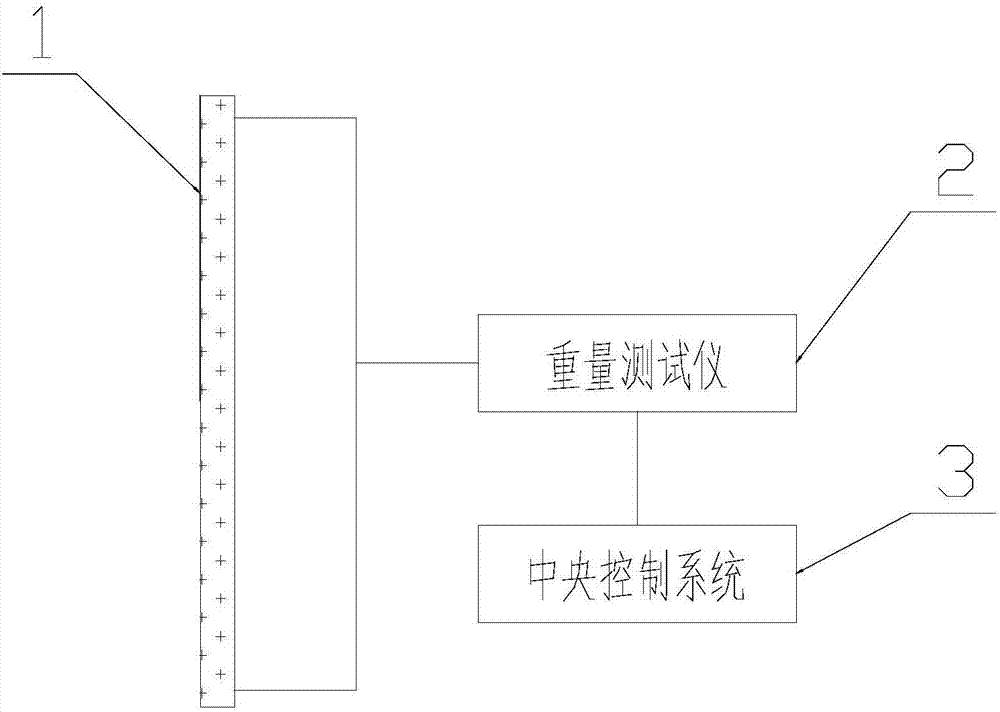

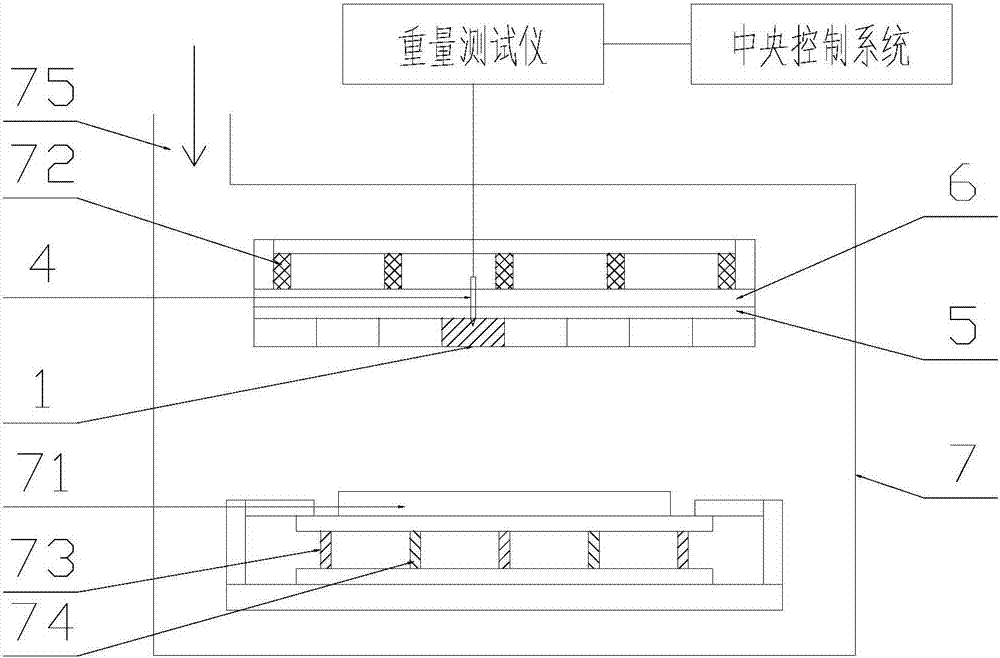

[0028] see figure 1 , which is a schematic structural diagram of a target consumption monitoring system used in a sputtering film forming device according to the present invention. As shown in the figure, the monitoring system proposed by the present invention includes a target 1 arranged in a sputtering film forming device, two ends of the target 1 are connected with a weight tester 2, and the weight tester 2 is connected with a central control system 3 .

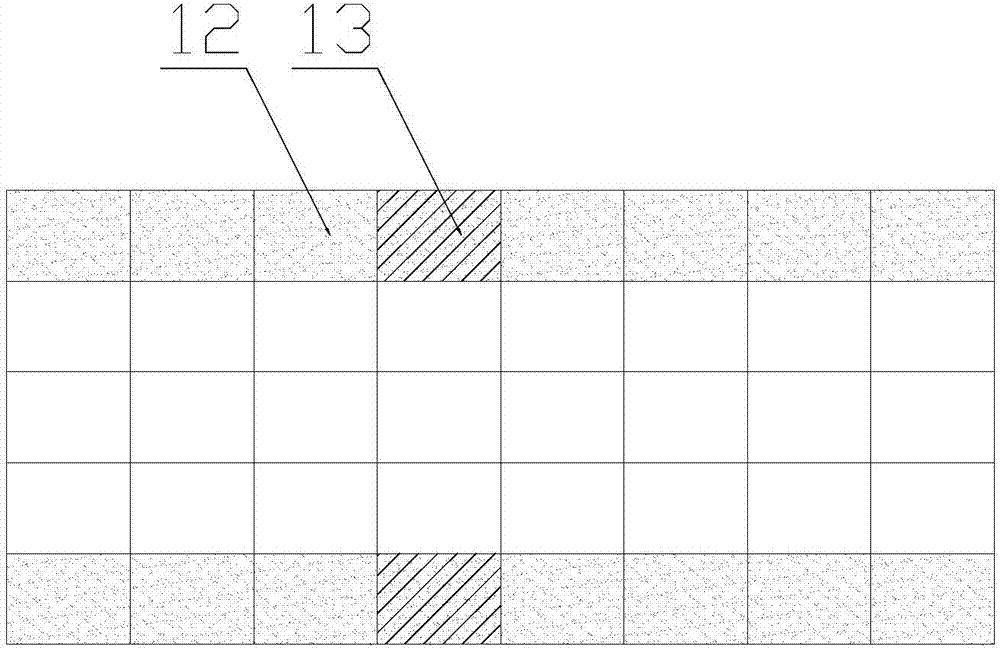

[0029] The target 1 is the monitoring object in the present invention. It is located inside the sputtering film forming device and is a very important part in the sputtering film forming process. The reasonable use of the target 1 can ensure the quality of the film forming. In order to avoid the breakdown of the target 1 in the present invention, it is necessary to ensure that every position of the target 1 will not b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com