Full-automatic chain saw timber-sawing equipment

An automatic sawing device and fully automatic technology, applied in the direction of sawing equipment, chain saws, sawing components, etc., can solve the problems of time-consuming and laborious manual sawing, difficulty in grasping the state of the chain saw, etc., to reduce labor intensity and manpower cost, ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

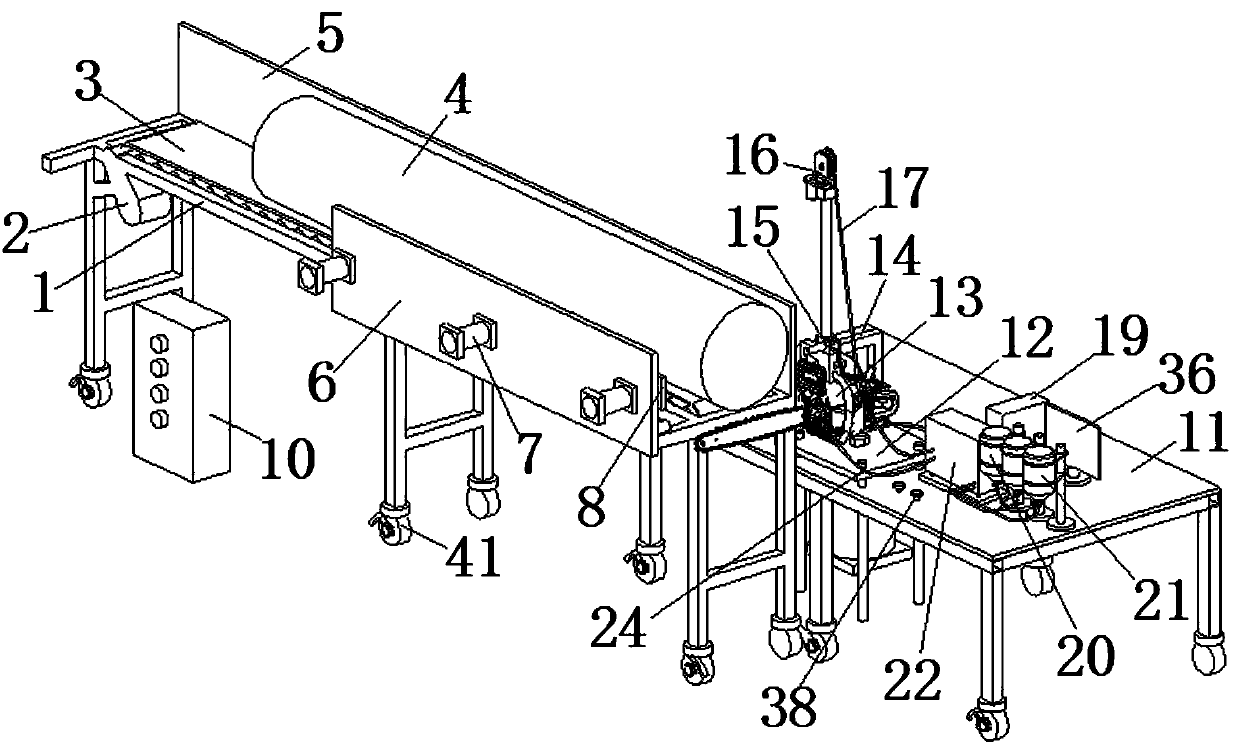

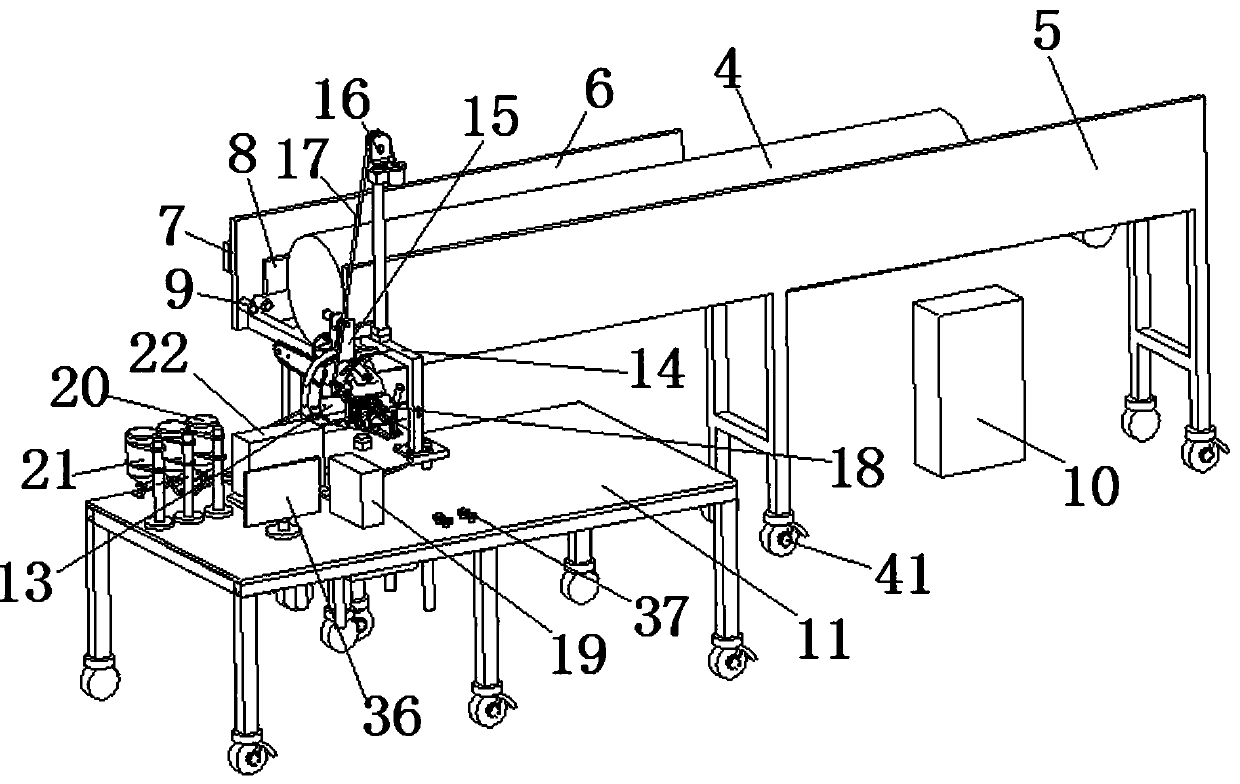

[0025] Such as Figure 1-Figure 6 As shown, a fully automatic chainsaw sawing equipment, including a wood feeding device, a chainsaw automatic sawing device, wherein:

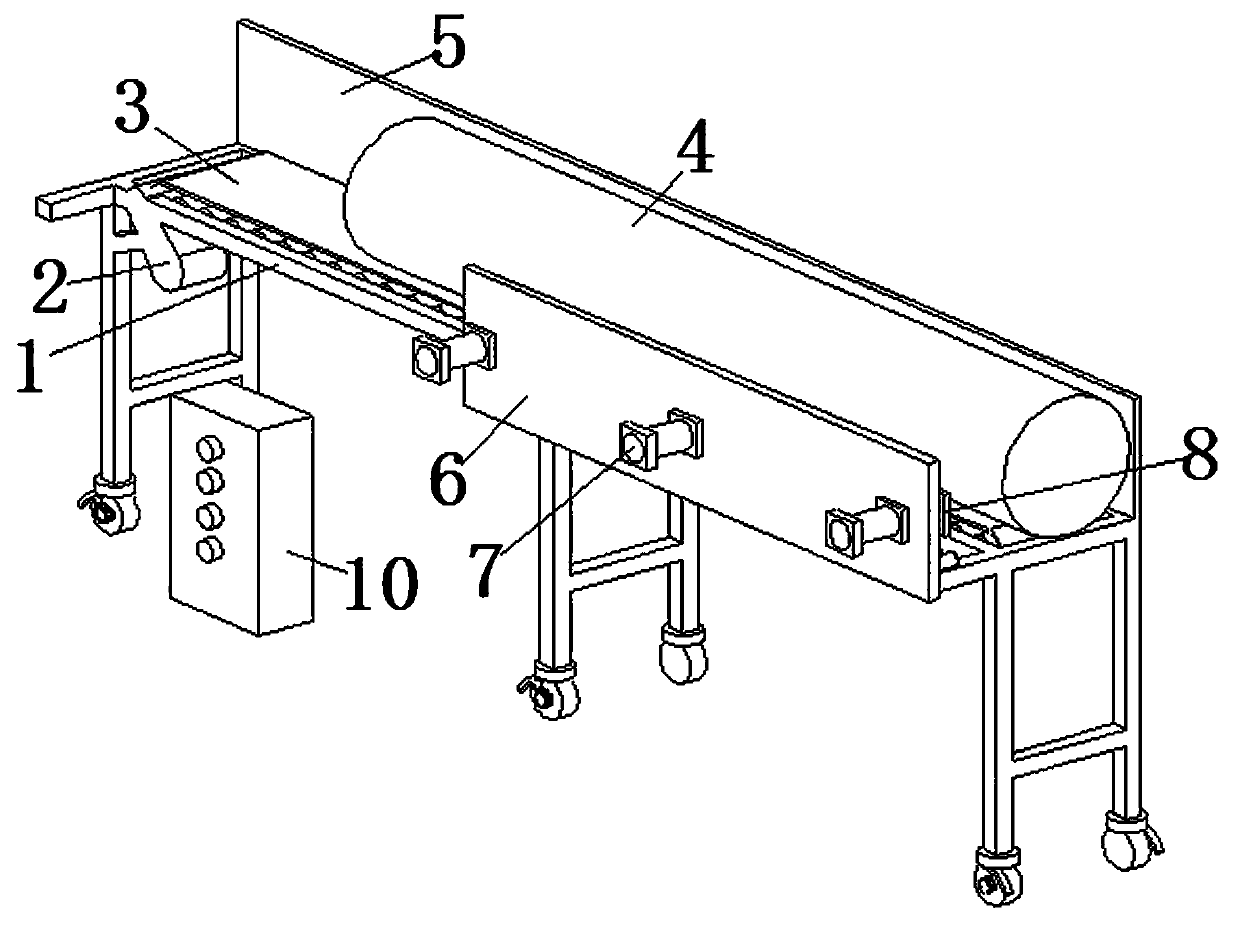

[0026] The wood feeding device includes a horizontal transmission frame 1. A transmission belt 3 driven by a motor 2 is installed in the transmission frame 1. The transmission belt 3 supports and transports wood 4. The transmission frame 1 is connected upwards on one side corresponding to the transmission direction. There is a limit plate 5, and the other side of the transmission frame 1 corresponding to the transmission direction is upwardly connected with a mounting plate 6. The mounting plate 6 is opposite to the limit plate 5, and the mounting plate 6 is fixed on the outer surface corresponding to the rear position of the transmission direction. There are multiple groups of clamping...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com