Fabricated steel-concrete structure light composite external wall plate

A technology of composite exterior wall panels and steel-concrete structures, which is applied in the direction of walls, building components, and building structures, can solve problems affecting the overall quality of prefabricated buildings and inconvenience for users, so as to increase the effect of thermal insulation and sound insulation, reduce The effect of sheet thickness and strong ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the structure described below.

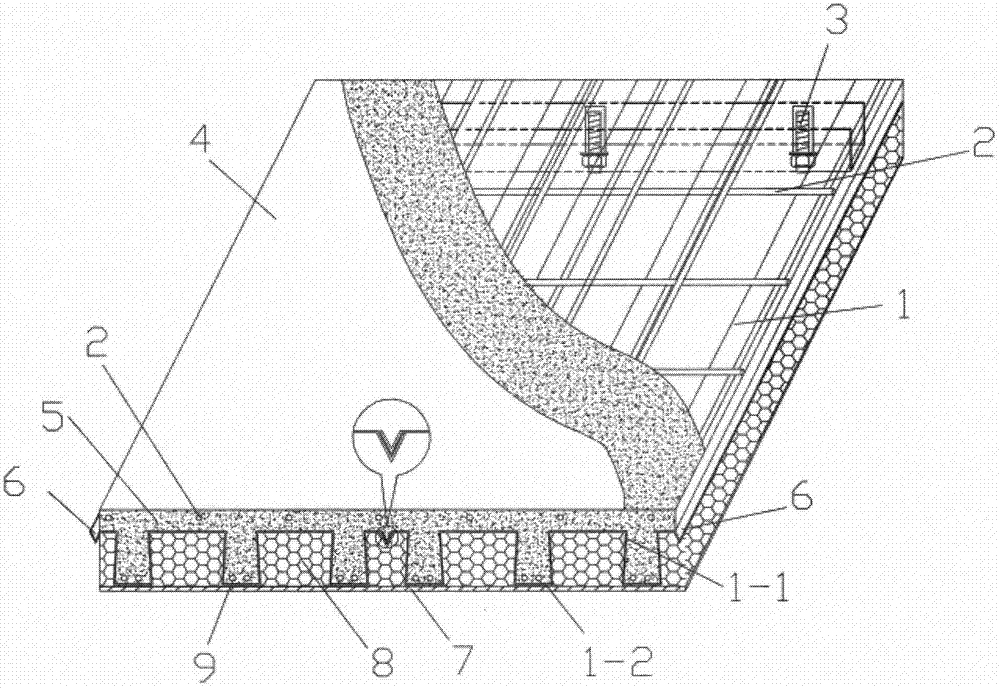

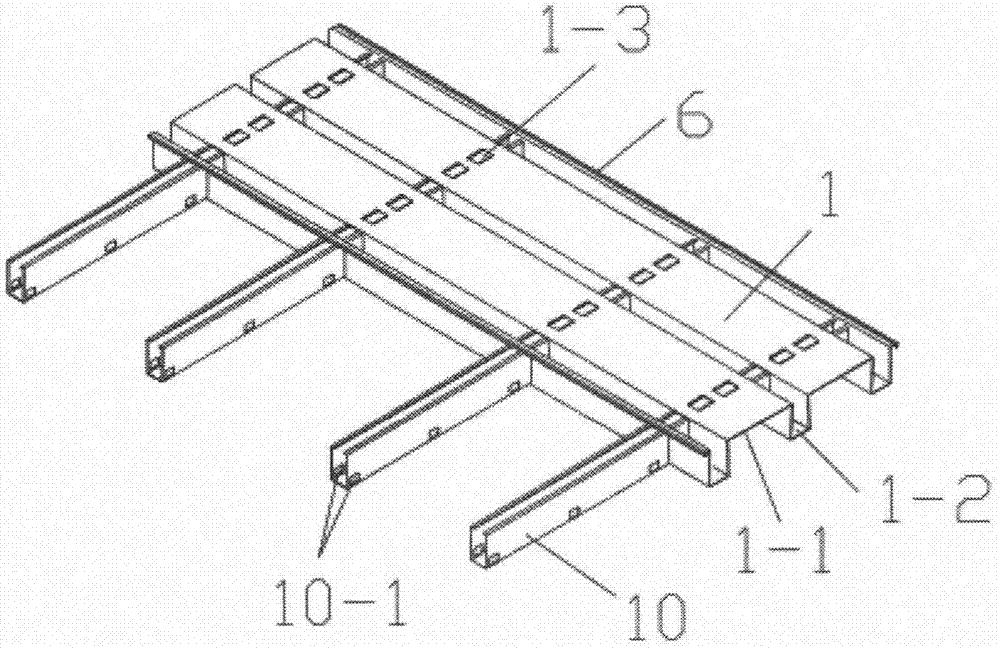

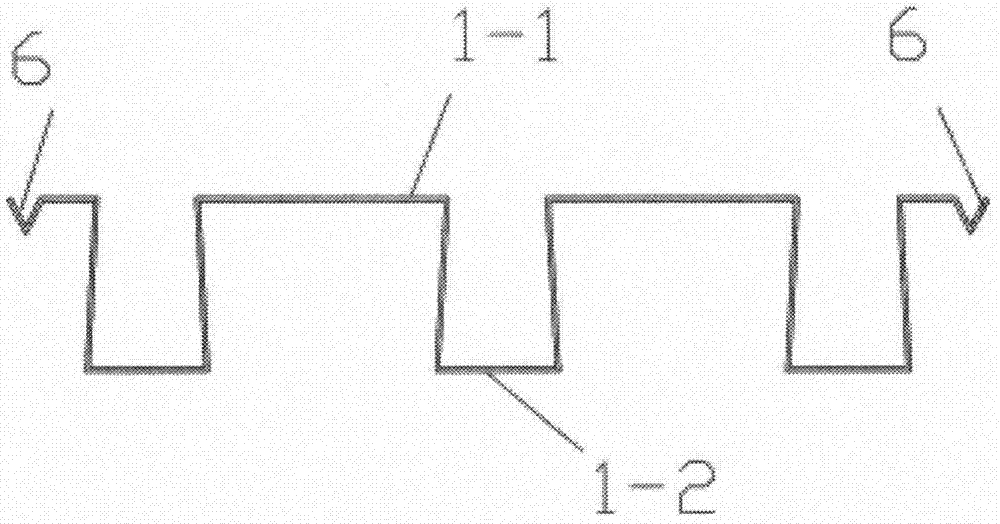

[0027] like Figure 1 to Figure 3 As shown, a light-weight composite exterior wall panel of fabricated steel-concrete structure, which includes a wavy steel plate with crests and troughs along the lateral pressure (width direction) of the exterior wall panel 1, light bone poured on the outer surface of the steel plate Material concrete layer 5, foam concrete layer 8 poured on the inner surface of the steel plate, decorative surface layer 4 covering the surface of the lightweight aggregate concrete layer, glass fiber grid sheet 7 laid on the surface of the foam concrete layer, and the two sides of the steel plate are respectively There are V-shaped grooves 6 extending longitudinally. When two exterior wall panels are overlapped, the V-shaped grooves on one side can accommodate the V-shaped groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com