Skylight structure convenient to install and skylight installation method

A technology that is convenient for installation and installation method, applied in the direction of skylight/dome, building structure, roof, etc., to achieve the effect of quick installation and good anti-seepage and water sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

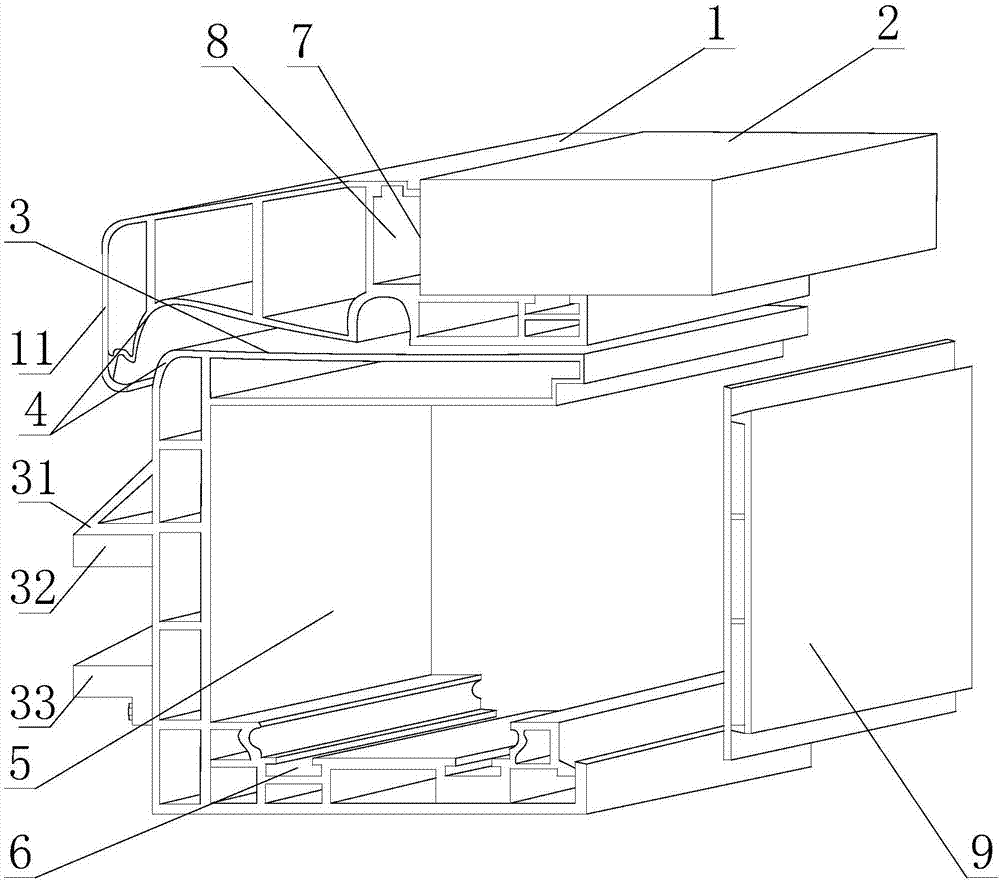

[0029] Such as figure 1 As shown, the easy-to-install skylight structure and the installation method of the skylight include a window frame 3, a sash frame 1 and a sash glass 2 installed on the sash frame 1, and the sash frame 1 is installed on the top of the sash frame 3, and the window An overlapping edge 31 is also provided on the outer surface of the frame 3, the overlapping edge 31 protrudes outward relative to the outer surface of the window frame 3, and the overlapping edge 31 forms a closed ring around the circumference of the window frame 3, All points on the bottom surface of the overlapping edge 31 are located on the same plane;

[0030] A sealing strip 32 is also fixed on the bottom surface of the overlapping edge 31 , and the sealing strip 32 forms a closed ring around the circumference of the window frame 3 .

[0031] Specifically, the overlapping edge 31 set above is equivalent to the flange on the outside of the window frame 3, and is used to provide support f...

Embodiment 2

[0033] Such as figure 1 As shown, this embodiment is further limited on the basis of Embodiment 1: the projection of the outer edge of the upper end of the window frame 3 to the sash frame 1 falls within the outer edge of the lower end of the sash frame 1, and the outer edge of the sash frame 1 A frame edge 11 protruding to one side of the window frame 3 is also provided on the side of the window frame 3, and the frame edge 11 is located on the outside of the upper outer side of the sash frame 1, and at the corner outside the upper end of the window frame 3, the frame edge 11 The junctions with the lower surface of the sash frame 1 are arc-shaped chamfers 4 .

[0034] In this solution, by limiting the positional relationship between the outer side of the upper end of the window frame 3 and the sash frame 1, the window frame 3 can be completely covered below the sash frame 1, thus, to a certain extent, the direction of the edge of the sash frame 1 to the window can be solved. ...

Embodiment 3

[0043] This embodiment provides a method for installing a skylight structure that can be used in any one of the technical solutions provided by any of the above embodiments: a method for installing a skylight, which is used to install the skylight on the top floor of a building In the reserved skylight installation hole, the installation method is to place the window frame 3 in any one of the above-mentioned conveniently installed skylight structures in the way of overall hoisting, and place the window frame 3 from above the installation hole In the skylight installation hole, the shape and size of the closed ring surrounded by the overlapping edge 31 need to meet the following relationship: the projection of the edge of the upper side of the skylight installation hole to the plane where the bottom surface of the overlapping edge 31 falls on On the bottom surface of the overlapping edge 31, the sealing strip 32 is located between the outer edge of the overlapping edge 31 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com