Machined-mounted hydraulic anchor rod drilling equipment

A hydraulic and bolt technology, which is applied in mining equipment, bolt installation, earth-moving drilling, etc., can solve problems such as difficult adaptation, impact on cutting performance of roadheader, inconvenient operation of roadheader, etc., and achieves convenient fixation and good promotion prospects. , easy to move and disassemble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the objectives, technical solutions and advantages of the present invention more clearly understood, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

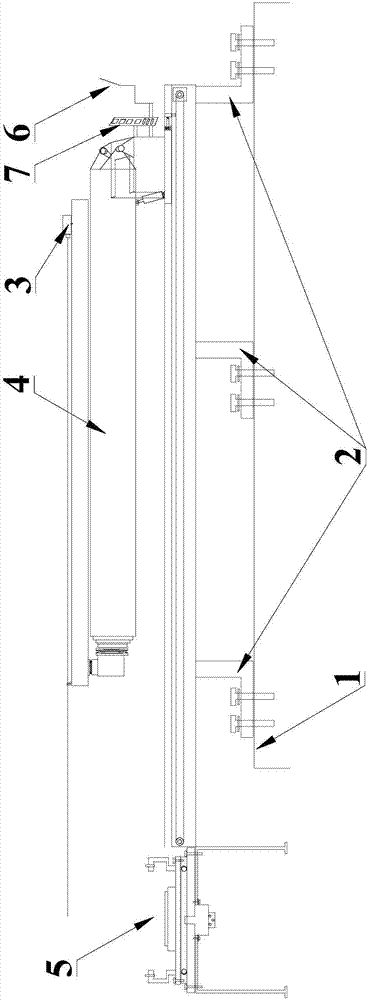

[0036] An airborne hydraulic bolt drilling equipment, such as figure 1 As shown, the rock bolt drilling equipment is fixed on the roadheader 1 through the fixing unit 2, and the hydraulic system of the roadheader 1 provides power to the rock bolt drilling equipment, so there is no need to provide additional power to the rock bolt drilling equipment. Equipped with a power unit, the structure is simplified; the rock bolt drilling equipment includes a hydraulic bolt machine 3 and a moving unit 4 ; the moving unit 4 includes a movable seat 41 , a longitudinal moving mechanism 42 and a lateral moving mechanism 43 .

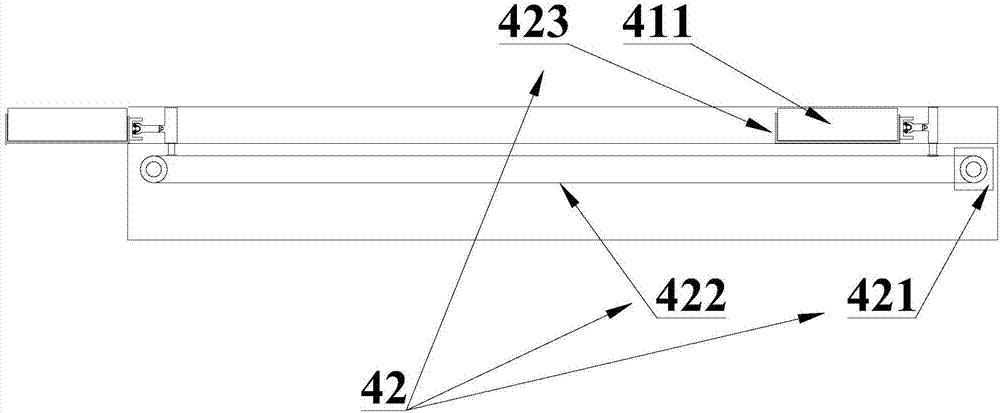

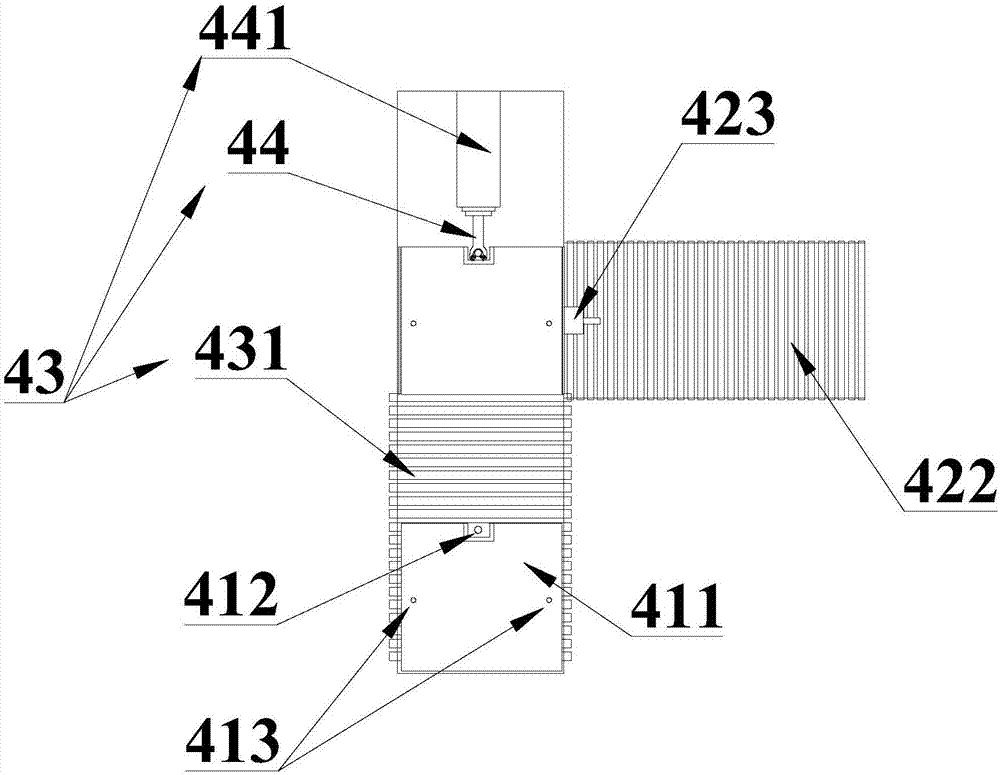

[0037] refer to figure 2 , the bottom of the movable seat 41 is provided with a card pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com