Fluidity tester

A tester and fluidity technology, applied in the direction of flow characteristics, instruments, measuring devices, etc., can solve the problems of inaccuracy, inability to display, and affect the adhesive bonding performance of the adhesive, so as to achieve simple structure of the device, ensure fluidity, and make low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

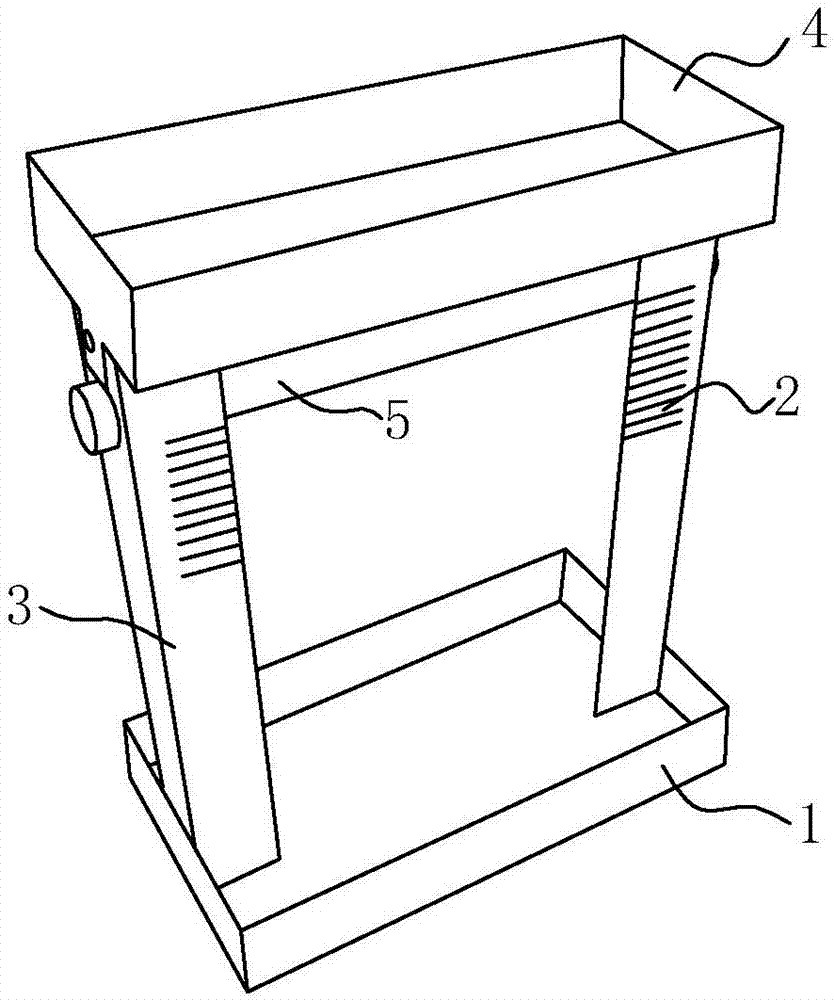

[0017] refer to Figure 1 to Figure 4 , a fluidity tester of the present invention, comprising a base 1, the base 1 is provided with a first pillar 2 and a second pillar 3, and a feed tank 4 is installed on the first pillar 2 and the second pillar 3 , the bottom of the feed tank 4 is provided with a discharge port 4-1, and the first pillar 2 and the second pillar 3 are horizontally equipped with a roller 5, and the roller 5 is adjacently arranged on the front of the discharge port 4-1. Below, the front of the first pillar 2 and the second pillar 3 is also provided with a scale, and the starting line of the scale is at the same level as the lowest point of the drum 5 .

[0018] refer to figure 1 , the first pillar 2 and the second pillar 3 are provided with a through hole for installing a roller 5, the roller 5 is inserted in the through hole, and the roller 5 can rotate freely in the through hole.

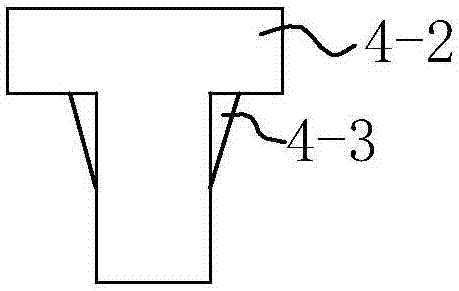

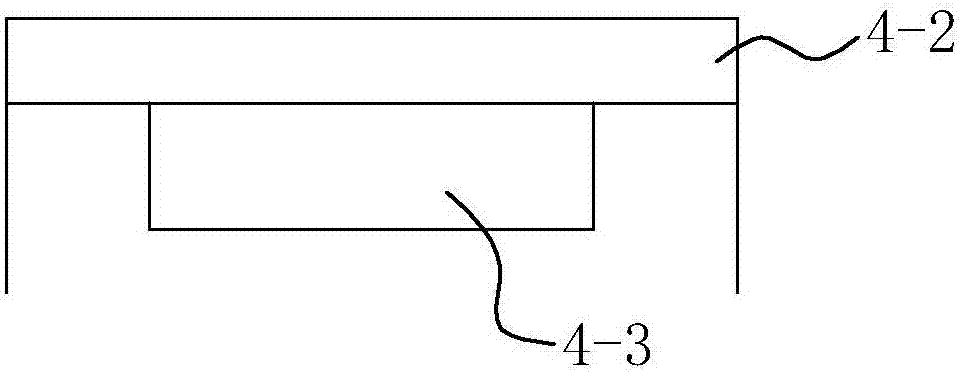

[0019] refer to Figure 2 to Figure 4 , the feed chute 4 is set in a funnel...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap