On-site dynamic detection method for surface mine

A dynamic detection and on-the-spot technology, applied in the field of mine exploration, can solve problems such as low precision, poor diversity of information results, and less measurement information, and achieve high precision and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

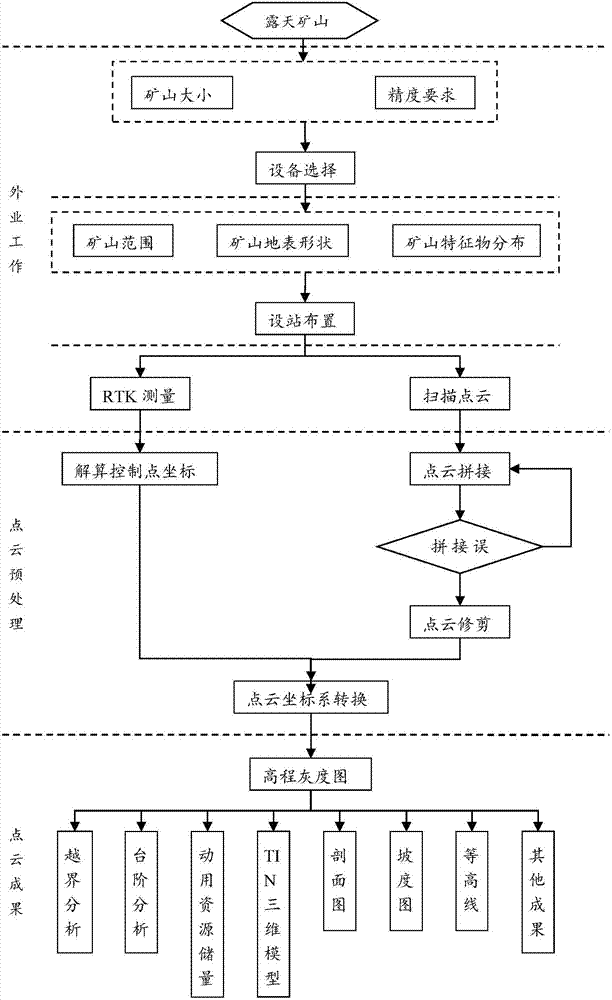

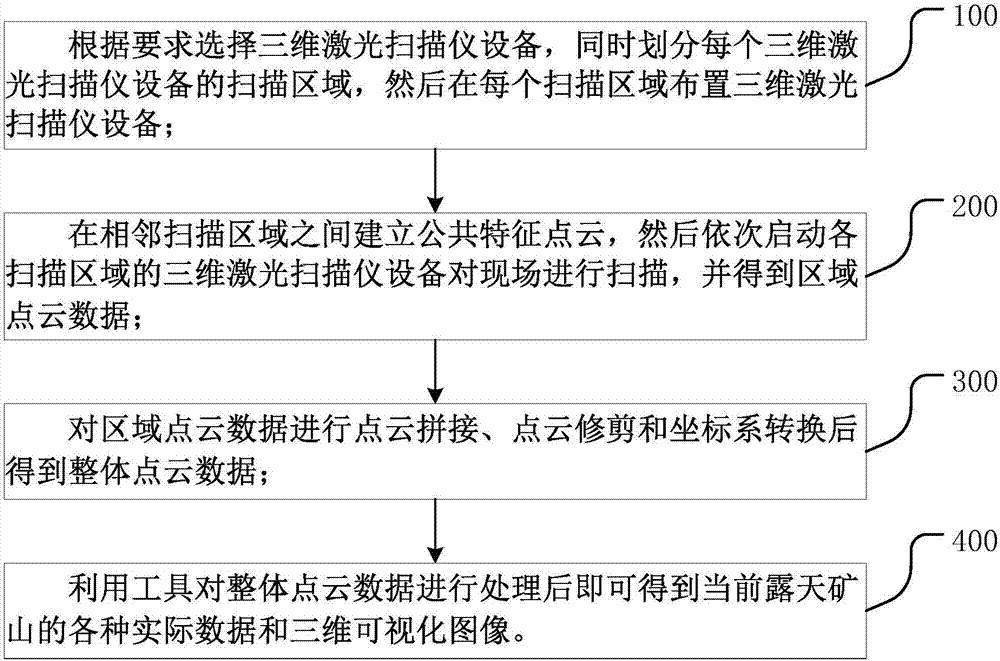

[0023] Such as figure 1 , 2 As shown, the on-the-spot dynamic detection method of the open-pit mine of an embodiment of the present invention generally comprises the following steps:

[0024] Step 100, select a 3D laser scanner device according to requirements, divide the scanning area of each 3D laser scanner device at the same time, and then arrange the 3D laser scanner device in each scanning area.

[0025] When selecting 3D laser scanner equipment, it is necessary to consider the size, accuracy and environmental suitability requirements of the current open-pit mine.

[0026] When dividing the scanning area, it is necessary to consider the overall scope of the open-pit mine, the stripping surface, the geomorphic shape of the on-site mining, the distribution of features, the on-site construction status equipment and the range that the 3D laser scanner equipment can cover, and then determine the 3D laser scanning. On-site station layout of instrumentation equipment.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com