Power supply structure

A technology of electrical components and plugs, applied in the direction of circuits, electrical components, conductive connections, etc., can solve the problems of poor installation performance and difficulty of motor 104, and achieve the effects of low manufacturing cost, restraining inclination, and improving installation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0079] Embodiments of the present invention will be described below based on the drawings.

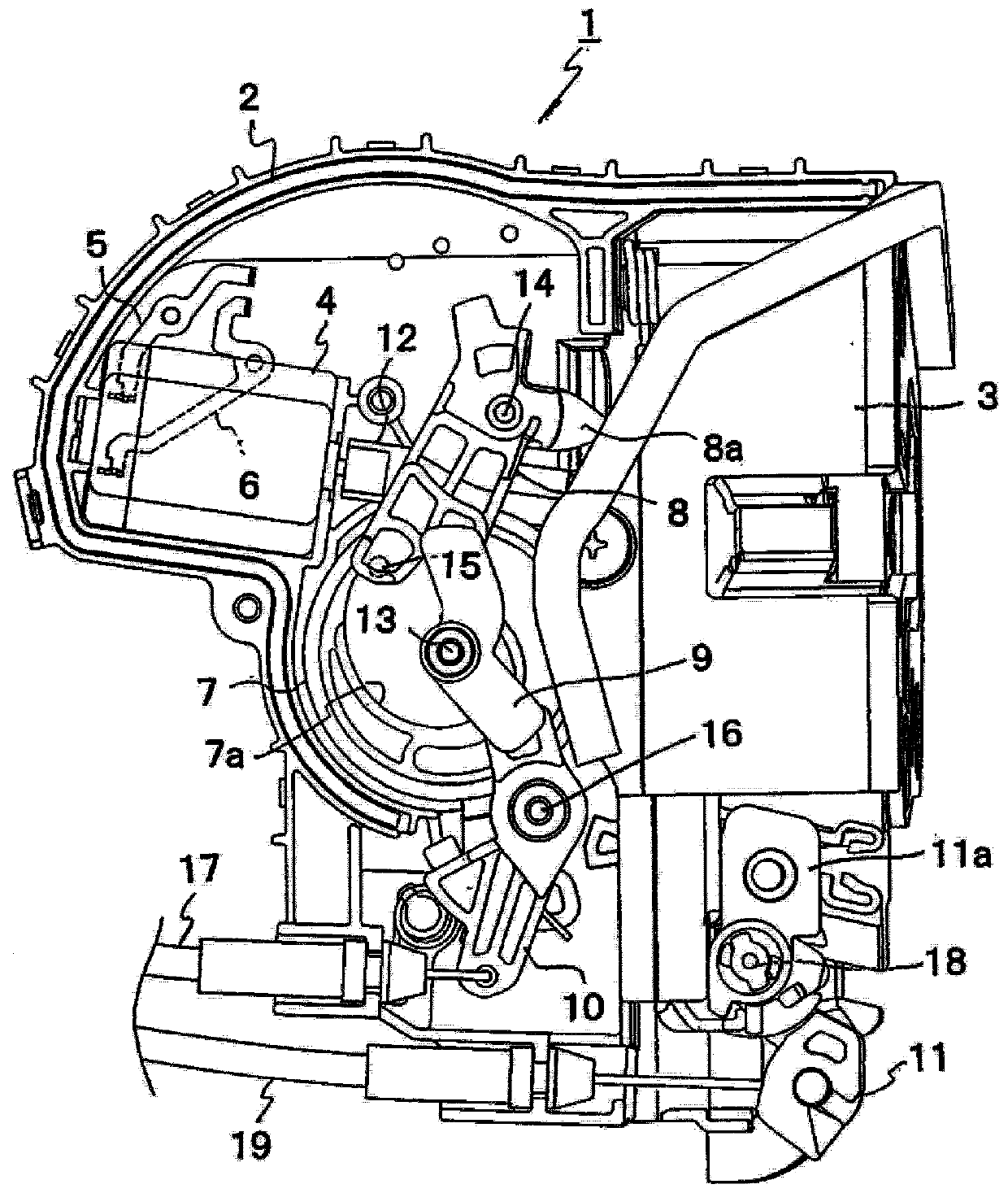

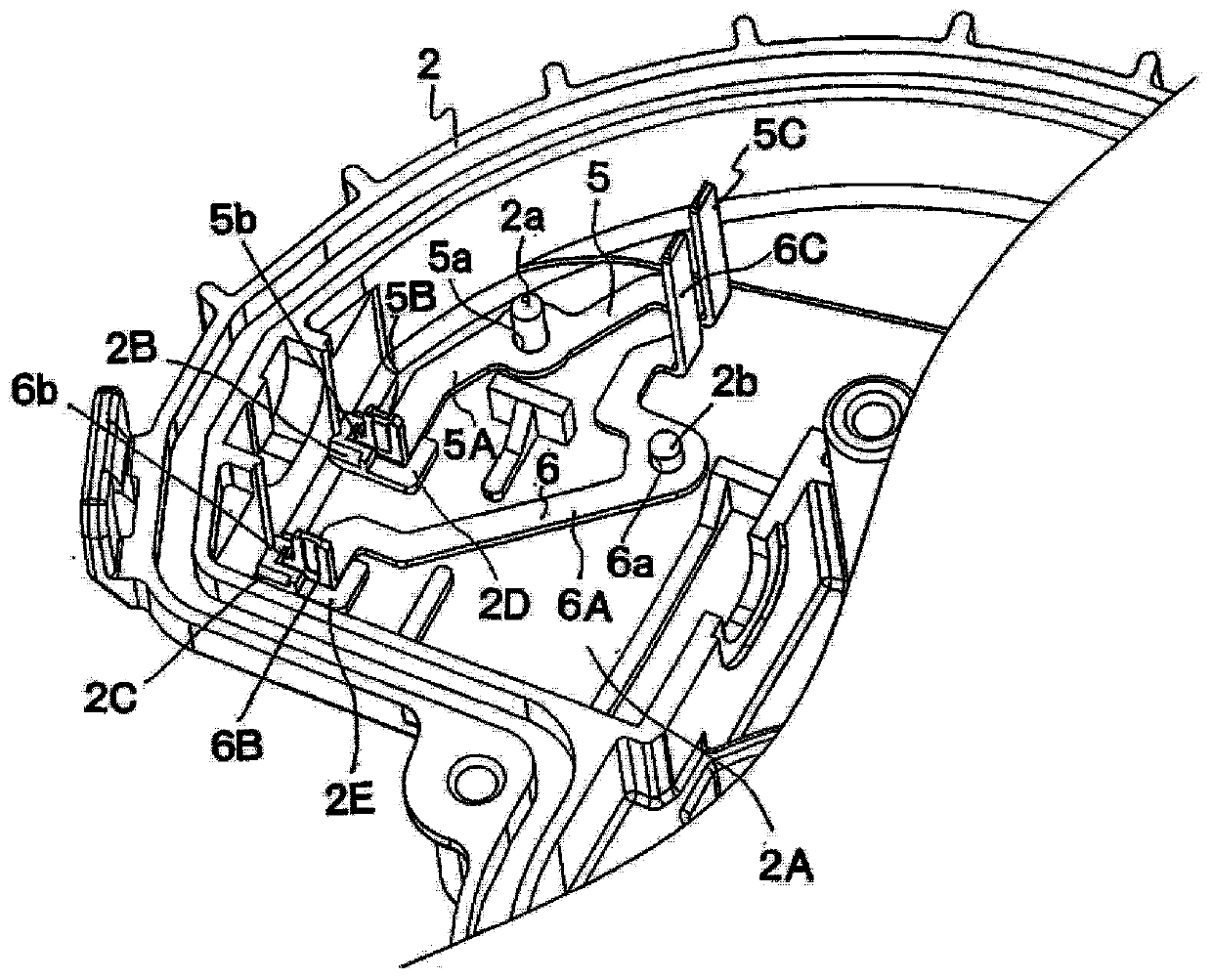

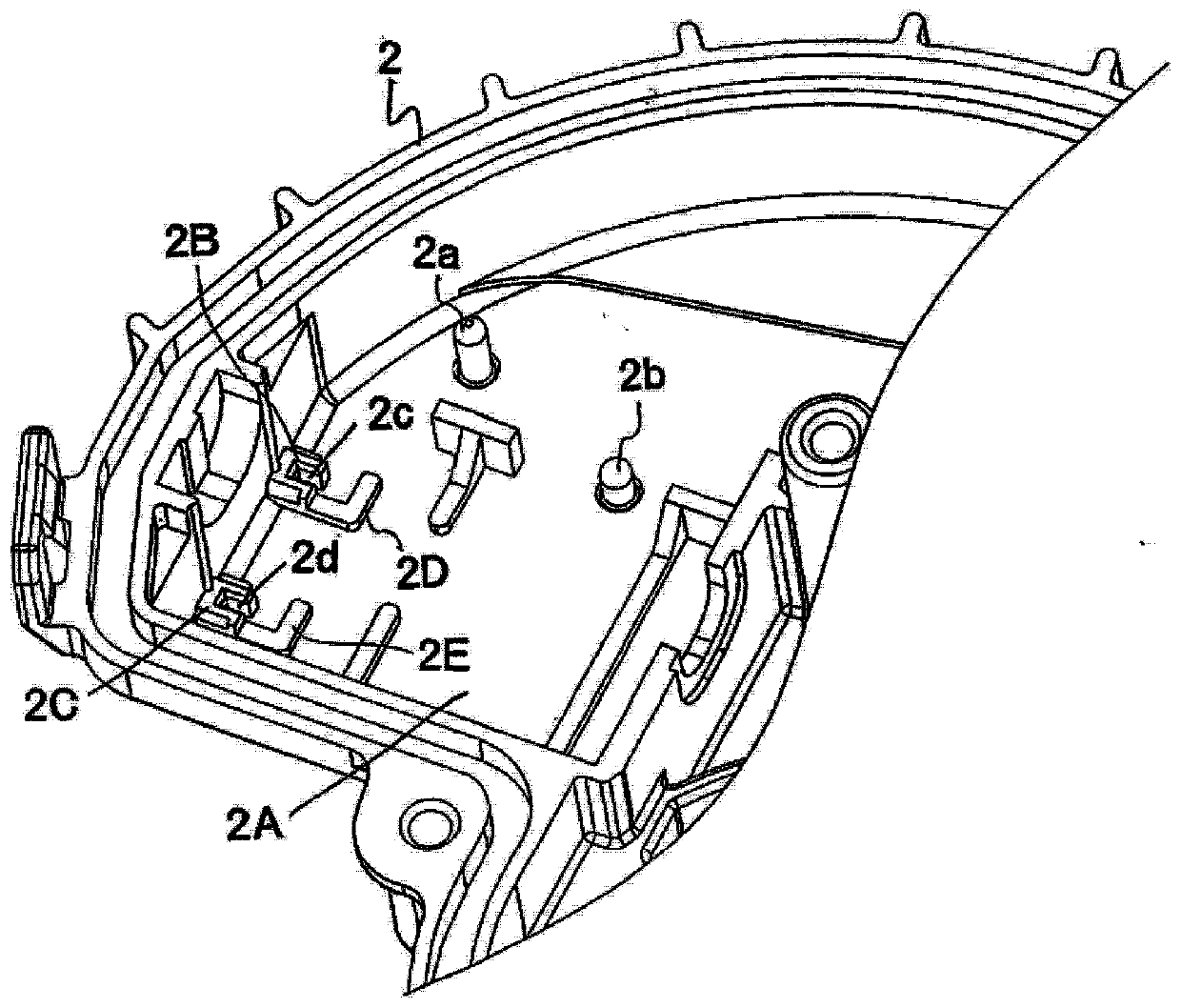

[0080] figure 1 It is a plan view showing the internal structure of a door lock device provided with a power supply structure for supplying power to a motor according to the present invention, figure 2 It is a partial perspective view showing the state before the motor is installed in the door lock device having the power supply structure, image 3 It is a partial perspective view of the lower case showing the state before the bus bar and the motor of the door lock device having the power supply structure are attached, Figure 4 is a plan view of the plug convex portion of the bus bar, Figure 5 is the front view of the plug protrusion of the bus bar, Image 6 is a partial plan view showing a state in which the plug protrusion of the bus bar is engaged with the support portion of the lower case, Figure 7 It is a partial sectional view showing the mounted state of the motor.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com