A mechanized harvesting method and equipment for longline cultured oysters

A harvesting method and oyster technology, applied in fish farming, application, animal husbandry, etc., can solve the problems of high labor consumption, low degree of mechanization, low efficiency, etc., to reduce labor intensity, improve the degree of automation, and simplify the process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

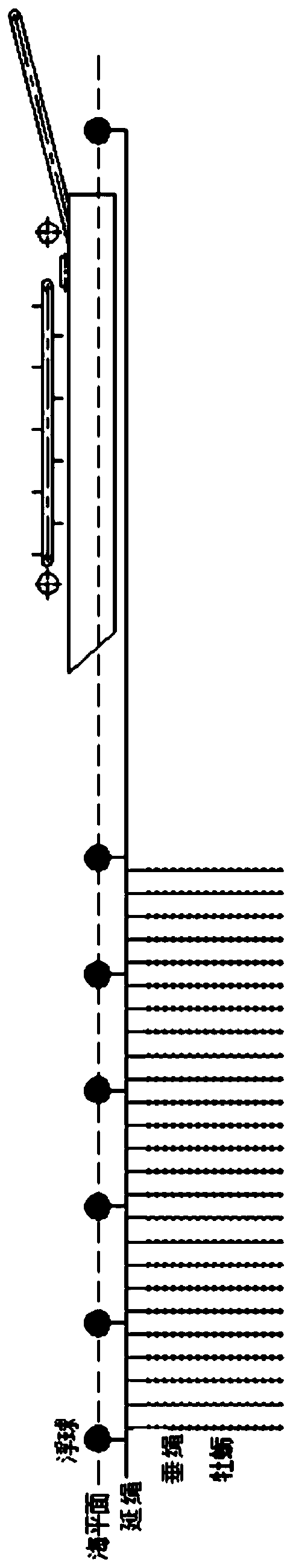

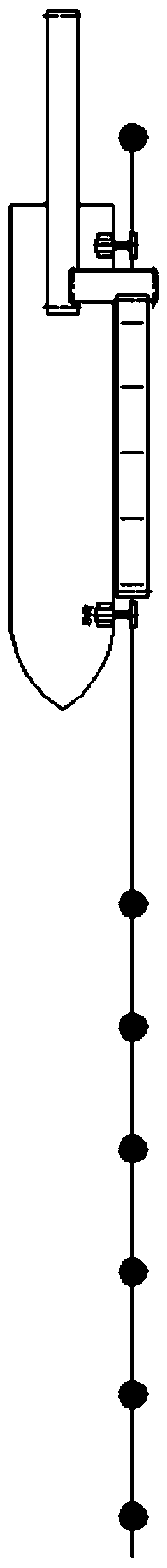

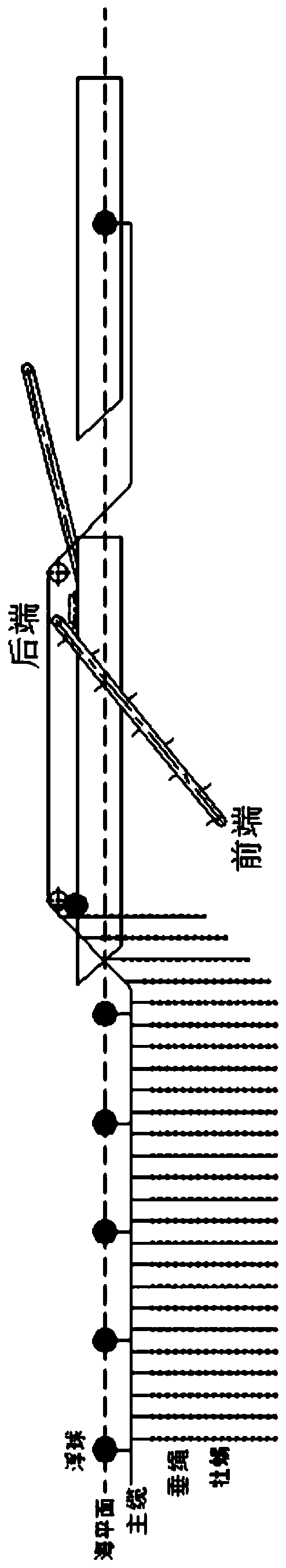

[0043] see Figure 1-6 , a mechanized harvesting device for longline cultured oysters, the harvesting device is fixedly arranged on a floating boat, and includes a first rocker conveyor, a second rocker conveyor, a transfer conveyor, a lifting device, and a guide wheel device; The first rocker conveyor is fixed on the side of the pontoon, and the front end can swing around the rear elevation; the second rocker conveyor is fixed behind the first rocker conveyor, and the rear end can swing around the front end. The facade swings; the first and second rocker conveyors are connected by a transfer conveyor; the lifting device is used to hook the longline to the low-position guide wheel device or the high-position guide wheel device; the first The rocker conveyor swings to an appropriate angle to accept the vertical rope. The guide wheel device drives the long rope to move slowly. The vertical rope is separated from the longline; the surface of the conveyor belt of the first convey...

Embodiment 2

[0050] see Figure 7 , 9 , 11. The difference between this embodiment and Embodiment 1 is that the guide wheel device also includes a high-position guide wheel device, and the lifting device hangs the longline on the high-position guide wheel device, so that the longline not only breaks away from the water surface, but also Make the vertical rope completely out of the water. When the shells are loosely attached and easy to fall off, harvest at a high position, which is convenient for the crew to monitor and improve the ability to respond to emergencies;

Embodiment 3

[0052] The difference between this embodiment and Embodiments 1 and 2 is that it also includes a lifting device, the guide wheel device is arranged on the lifting device, and the lifting device can raise the guide wheel device to an appropriate height, Thereby, the height of the guide wheel device can be adjusted freely, which is convenient for the crew to observe or operate.

[0053] In this embodiment, the mechanized harvesting equipment for longline cultured oysters is used for salvaging artificially cultured scallops.

[0054] During specific implementation, the following steps are included:

[0055] A) The pontoon travels to the side of the longline so that the position of the longline corresponds to the side;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com