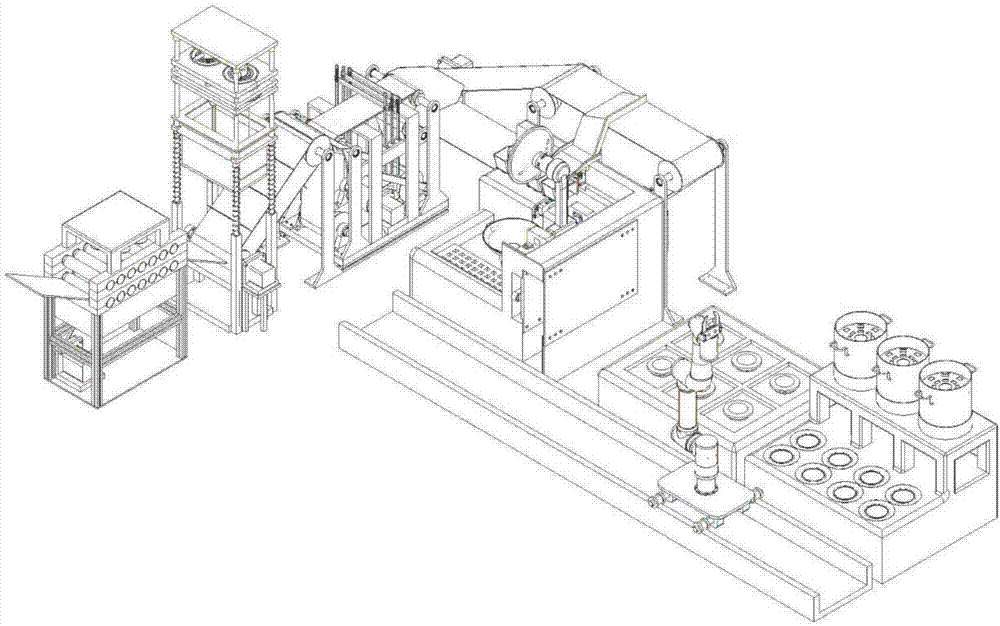

Multifunctional integral cooking machine

A cooking machine and multi-functional technology, which is applied to the structure of cooking utensils, cooking utensils, metal processing, etc., can solve problems such as the lack of a quantitative standard for cost control, the low work efficiency of chefs, and the limited work ability of back kitchens.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

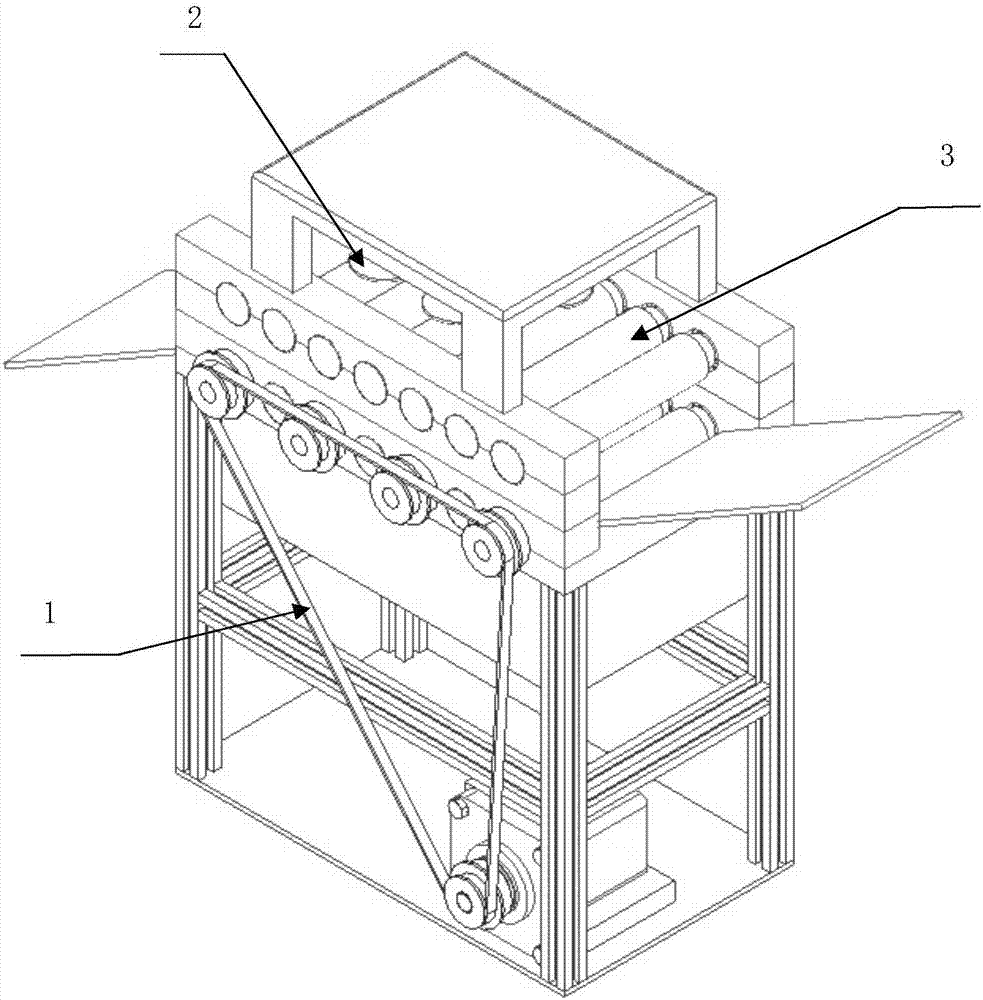

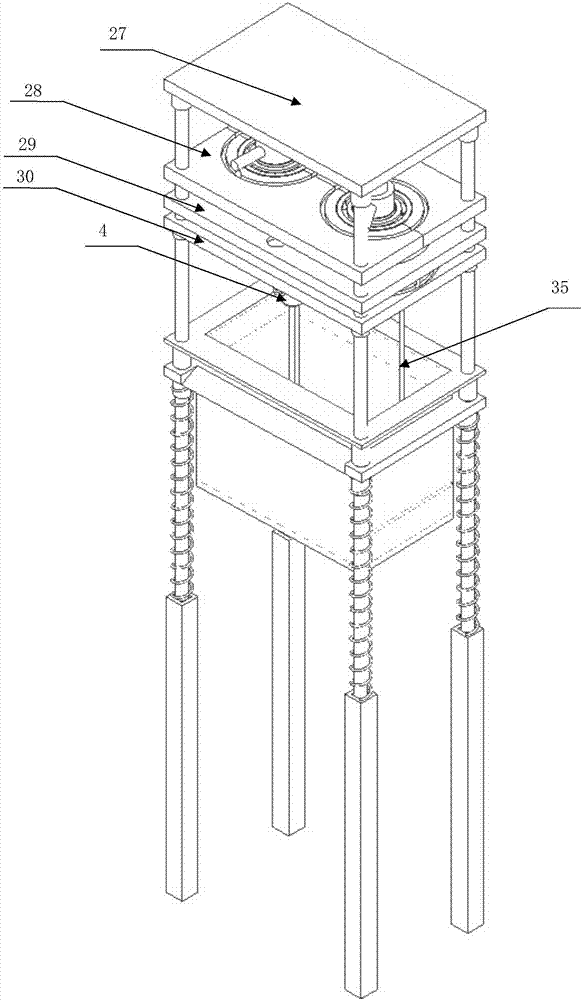

[0034]The function of the assembly line cooking food equipment is mainly realized by the mutual cooperation between the various machines. The roller brush cleaning machine cleans the rhizome food. Put the vegetables from the input port of the washing machine and roll them under the nozzle of the washing machine. Through the rotation of the motor, the belt (1) is driven to rotate, thereby causing the drum (3) of the cleaning mechanism to roll and carry vegetables to move forward. A fine hair brush is installed on the surface of the drum, and a pressure nozzle (2) is installed above the drum. When the vegetables are moving, the nozzle sprays water to cooperate with the rotation of the hair brush to remove the surface dirt of the root vegetables and achieve the purpose of washing vegetables. Finally, the washed vegetables slide down to the conveyor belt through the descending plate, and are transported to the vegetable cutter. The barrel washing machine cleans the root material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com