V-shaped double-cylinder type general engine fuel supply device

A technology for a fuel supply device and a general-purpose engine, which is applied to fuel injection devices, engine components, engine control, etc., can solve problems such as narrow engine covers, insufficient number of components, and differences in air-fuel ratios, achieving easy design and simple sharing. , the effect of eliminating exhaust gas restriction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the drawings.

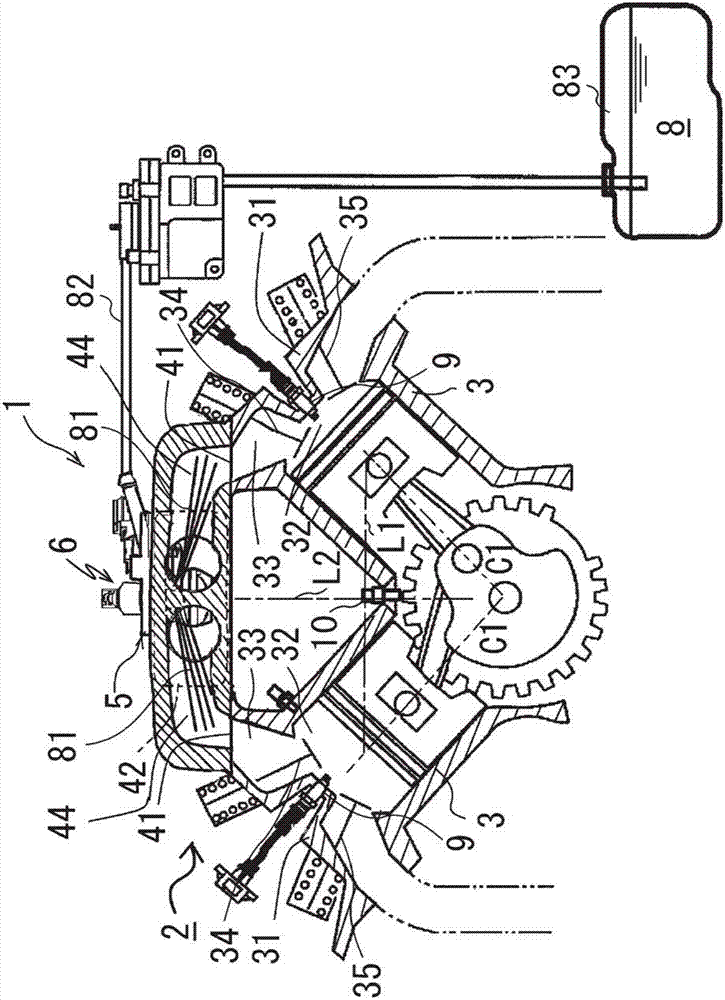

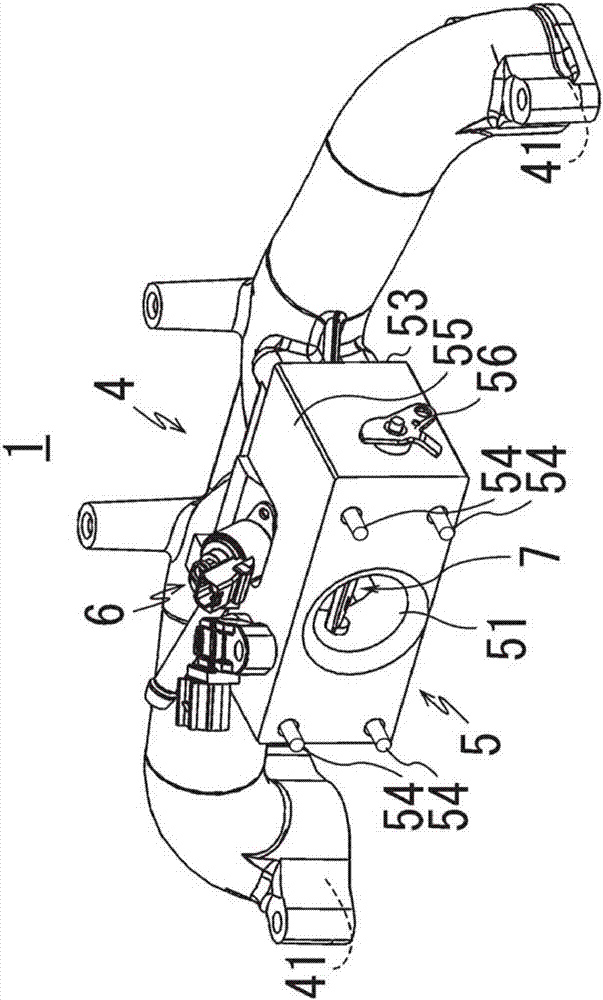

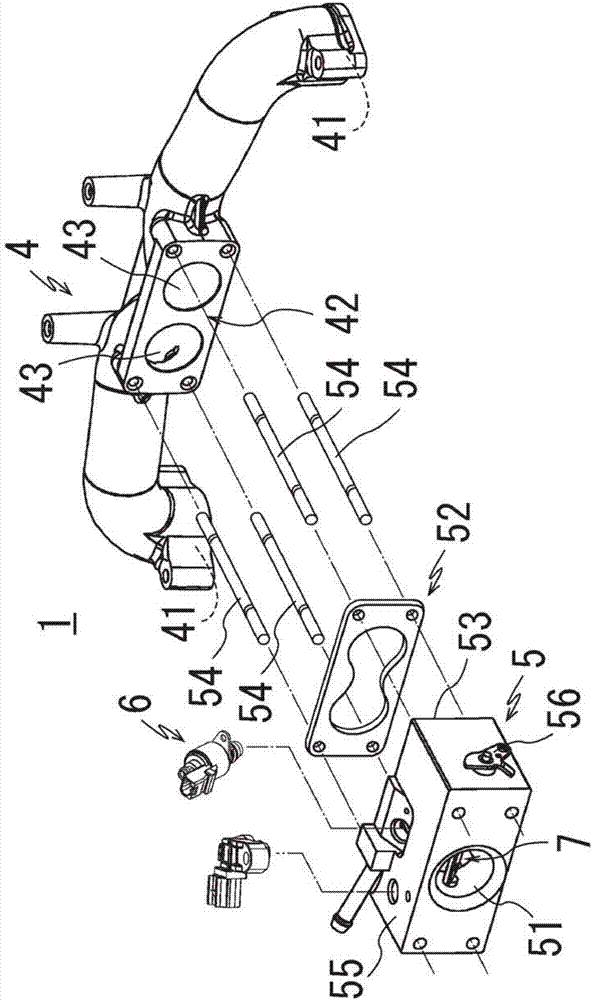

[0077] Figure 1 to Figure 6 It is a diagram showing a preferred embodiment when the present invention is implemented in a vertical output shaft type V-type general-purpose engine used in, for example, a passenger lawn mower, and the fuel supply device 1 is provided on a V-type two-cylinder general-purpose engine 2 For example, in an air-cooled general-purpose engine having a cylinder hole angle (Japanese: boa angle) of 90 degrees with cylinders 3 and 3, the fuel supply device 1 is mainly formed by an intake manifold 4 and a throttle body 5, wherein, The openings 41, 41 at both ends of the intake manifold 4 are connected to the intake ports 32, 32 of the cylinder heads 31, 31 of the cylinders 3, 3, and the throttle body 5 is connected to the intake ports formed on the intake manifold. 4 at the middle position of the planar connecting portion 42 conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com