Central cooler back-washing device for dredger

A central cooler and backwashing technology, applied in the field of dredging engineering, can solve the problems of dirty and blocked central central cooler filter, damaged titanium plate sealing rubber ring, many pollutants and microorganisms, etc., to reduce workload, easy to operate, Simple operation procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

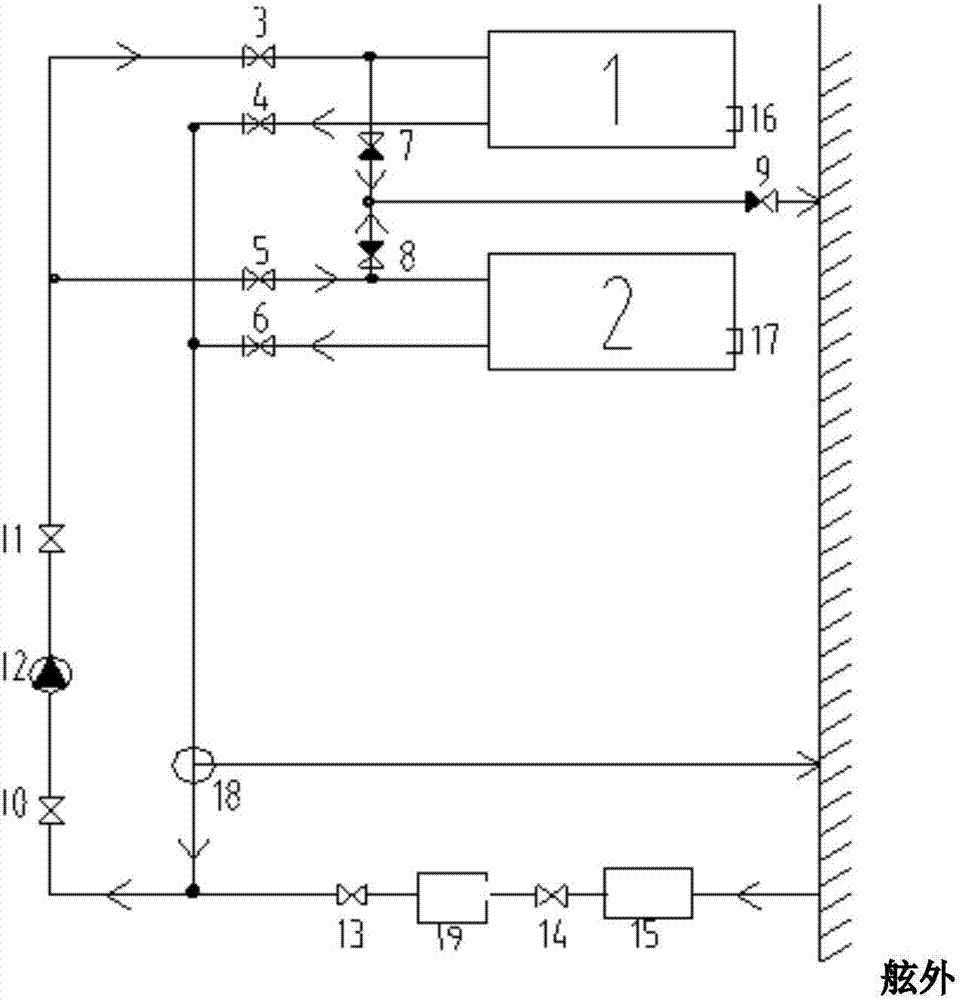

[0027] A central cooler backwashing device for a dredger, which is composed of a seawater pump, a valve and a pipeline. The inlet of the seawater pump is connected to the outboard through a valve and a seawater filter. The seawater outlet of one set of central cooler is connected to the seawater pump inlet pipeline and the outboard through the valve, and the pipeline between the seawater inlet of the two sets of central coolers and the valve is connected to the backwash stop check valve, and the backwash stop check valve passes through the pipeline through The sea valve is connected to the outboard.

[0028] The backwash stop check valve adopts DN100 stop check valve with a pipe diameter of 100mm. The sea valve uses DN100 cut-off check valve. The backwash stop check valve is made of copper, the pipeline is made of stainless steel or galvanized pipe, and the pressure level is greater than 0.3Mpa. The pipeline and the backwash stop check valve are connected by flanges, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com