Injection molding excess material removing device

A technology of residual material and material column, which is applied in the field of injection molding equipment to remove residual material, can solve the problems of reducing production efficiency, low safety of manual cutting of residual material, and taking a long time, so as to prevent injury, increase safety, and improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

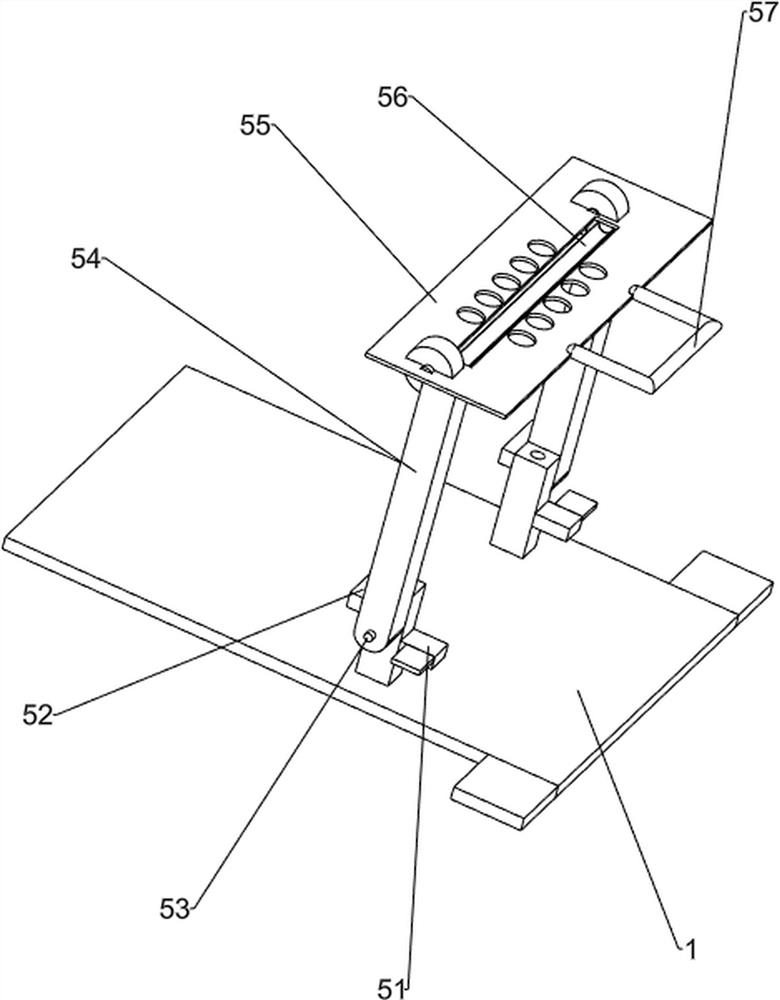

[0021] An injection molding removal device, such as figure 1 As shown, it includes a bottom frame 1, an upper plate 2, a support platform 3 and a cutting mechanism 4. The top of the bottom frame 1 is provided with an upper plate 2, and the left side of the bottom of the upper plate 2 is provided with a support platform 3. The top of the bottom frame 1 and the upper plate A cutting mechanism 4 is provided between the 2 bottoms.

[0022] When people want to use this device to cut off the finished product after injection molding, the finished product is manually put between a certain part of the cutting mechanism 4, and then a certain part of the cutting mechanism 4 is opened, and the cutting mechanism 4 cuts the finished product, and then A certain part of the cutting mechanism 4 is closed, and the finished product after cutting is collected.

Embodiment 2

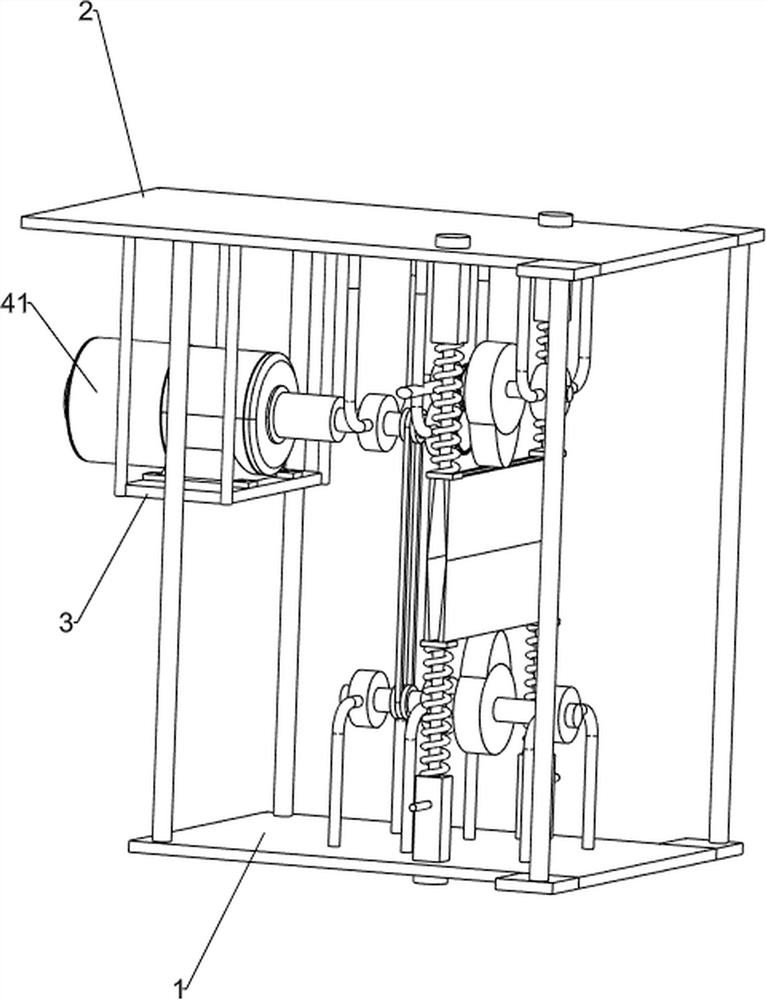

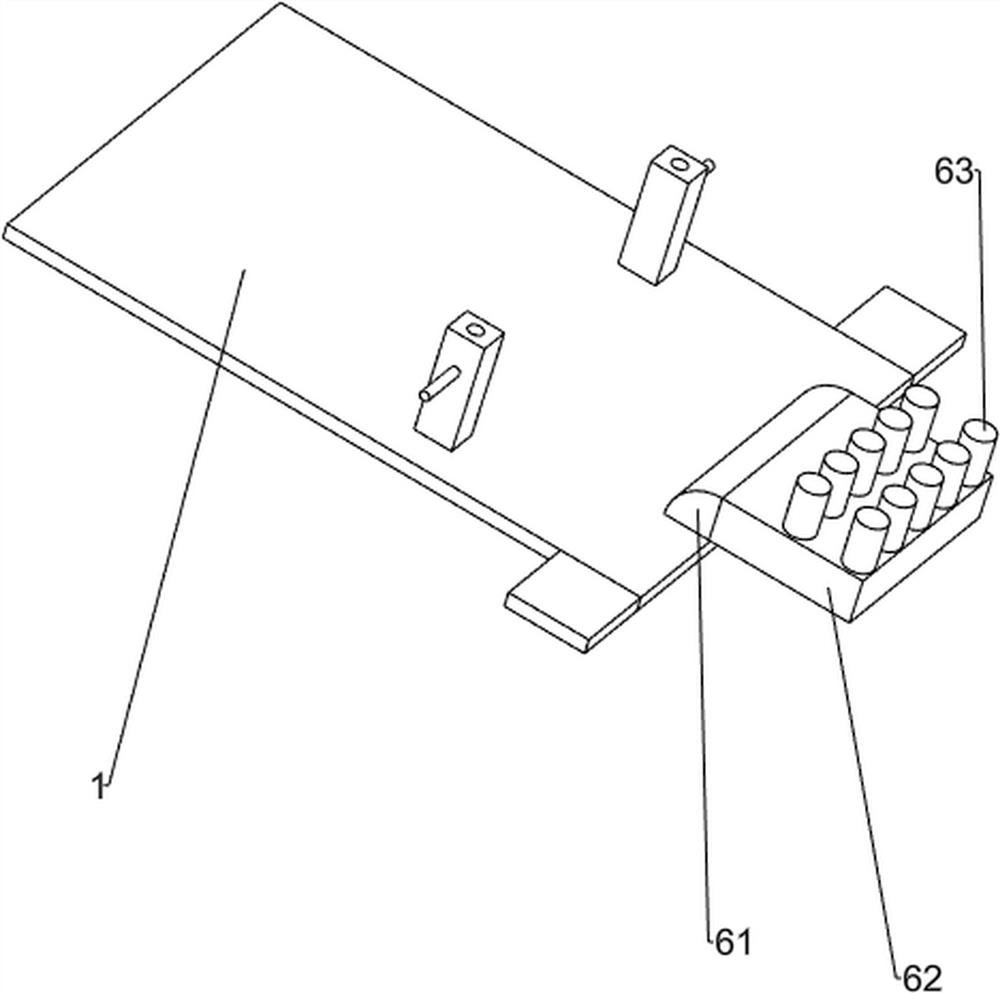

[0024] On the basis of Example 1, such as figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 As shown, the cutting mechanism 4 includes a motor 41, a first transmission shaft 42, a second transmission shaft 43, a third transmission shaft 44, a transmission gear set 45, a pulley assembly 46, an upper cam 47, a lower cam 48, an upper cutting knife group 49. Lower cutting knife group 410, spring 411 and long rod 412, motor 41 is provided on the support table 3, the output shaft of motor 41 is provided with a first transmission shaft 42, and the first transmission shaft 42 rotates with the left side of the bottom of the upper plate 2 Type connection, the bottom right side of the upper plate 2 is provided with a third transmission shaft 44, the middle of the third transmission shaft 44 is provided with an upper cam 47, and a transmission is provided between the right end of the first transmission shaft 42 and the left part of the third transmission shaft 44. Gear set 45...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com