Data integration method of intelligent industrial control network based on mirror port parsing

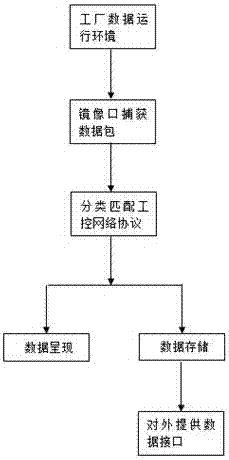

A technology of industrial control network and data integration, applied in bus network, comprehensive factory control, data exchange network, etc., can solve the problems of basic industrial facilities safety hazards, no hidden dangers, etc., and achieve the effect of strong feasibility and reduction of communication links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

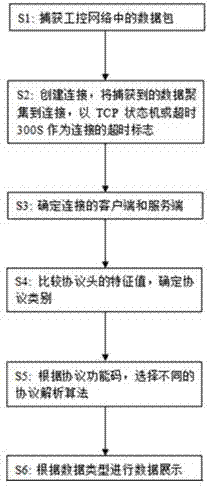

Method used

Image

Examples

example 1

[0041] Example 1, a data frame in the FINS protocol:

[0042] First, write 39 to the DW100 data on the host computer page, and at the same time capture the data through the mirror port, you can get the following data packets:

[0043] FINS protocol header: 46 49 4e 53 00 00 00 1e 00 00 00 02 00 00 00 00

[0044] FINS data segment: 80 00 02 00 01 00 00 ef 00 00 01 02 82 00 64 00 00 02 00 0042 1c

[0045] The most important part of it is as follows:

[0046] Memory write command: 01 02

[0047] Area Code: 82

[0048] Starting address: 00 64

[0049] Corresponding value: 00 00 42 1C

[0050] Parsing result: 00 64 converted to decimal is 100, the data type corresponding to the area code is Dword, 00 00 42 1C is 39 through the float hexadecimal parsing algorithm. The instrument corresponding to this value in the PLC is temperature, so the temperature data of a certain environment on site can be obtained through analysis of the mirror port.

example 2

[0051] Example 2: A data frame in the S7 protocol:

[0052]First, write 13 to the data of DB2.DBD0 on the host computer page, and at the same time capture the data packets through the mirror port, and the following data packets can be obtained:

[0053] S7 protocol header: 32 01 00 0c 00 00 0e 00 08 05 01 12 0a 10

[0054] S7 data segment: 02 00 04 00 02 84 00 00 00 00 04 00 20 41 50 00 00

[0055] The most important part of it is as follows:

[0056] Function code type: 02

[0057] Data block address: 00 02

[0058] Area code: 84 00

[0059] Data offset address: 00 00

[0060] Corresponding value: 41 50 00 00

[0061] Analysis result: 00 02 is resolved to DB2, the offset address is resolved to 0, and the corresponding value is resolved to 13. The instrument corresponding to this value in the PLC is the liquid level height, so the liquid level data of a certain environment on site can be obtained through the analysis of the mirror port .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com