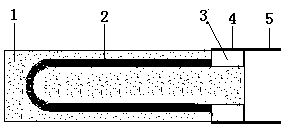

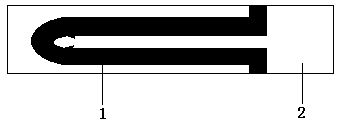

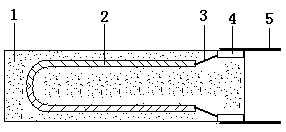

High-power silicon nitride ceramic heating sheet and its manufacturing method with hard inside and soft outside

A silicon nitride ceramic, high-power technology, applied in the field of silicon nitride ceramics, can solve problems such as difficult welding of lead wires, unstable power, uneven heating, etc., and achieve the effects of accurate resistance, firm outlet, and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Embodiment 1, cigarette lighter, specification 90X5X4mm, 500 watts, 1100°C, processed to 1100°C within 10 seconds.

[0053] 1. Insulating ceramic material: silicon nitride Si 3 N 4 , 94%; Ytterbium oxide Y 2 o 3 , 1-3%; aluminum oxide Al 2 o 3 , 0.5-1.5%; magnesium oxide MgO, 0.2-0.5%; lanthanum trioxide La 2 o 3 , 0.5-1%; hafnium oxide HfO 2 , 0.2-0.5%, aluminum nitride AlN, 0.5-2%, the weight of all components is 100%.

[0054] 2. Heating ceramic material: silicon nitride Si 3 N 4 , 45%, solid solution of titanium carbide and titanium nitride, Ti (C, N), 26-35%; the weight ratio of titanium carbide and titanium nitride in the solid solution is 4:6; molybdenum powder Mo, 0.5-3%; Nano nickel Ni, 0.5-1.0%; Niobium carbide CHNb, 0.2%; Whisker silicon carbide SiC, 0.2-0.5%; Molybdenum silicide MoSi 2 , 0.1-0.2%; silicon oxide SiO 2 , 0.1-0.2%; alumina Al 2 o 3 , 5-10%, the weight of all components is 100%.

[0055] 3. Welding ceramic materials: titanium ...

Embodiment 2

[0064] Embodiment 2. Drying sheet, specification 1200X12X4mm, 600 watts, processed to 258°C in 2 seconds, durability for 2 years. Among the weight ratios of the three ceramic materials,

[0065] 1. Insulating ceramic material: silicon nitride Si 3 N 4 , 93%; Ytterbium oxide Y 2 o 3 , 1-3%; aluminum oxide Al 2 o 3 , 0.5-1.5%; magnesium oxide MgO, 0.2-0.5%; lanthanum trioxide La 2 o 3 , 0.5-1%; hafnium oxide HfO 2 , 0.2-0.5%, aluminum nitride AlN, 0.5-2%, the weight of all components is 100%.

[0066] 2. Heating ceramic material: silicon nitride Si 3 N 4 , 45%, solid solution of titanium carbide and titanium nitride, Ti (C, N), 26-35%; the weight ratio of titanium carbide and titanium nitride in the solid solution is 4:6; molybdenum powder Mo, 0.5-3%; Nano nickel Ni, 0.5-1.0%; Niobium carbide CHNb, 0.2%; Whisker silicon carbide SiC, 0.2-0.5%; Molybdenum silicide MoSi 2 , 0.1-0.2%; silicon oxide SiO 2 , 0.1-0.2%; alumina Al 2 o 3 , 5-10%, the weight of all comp...

Embodiment 3

[0069] Embodiment 3, a heating chip, the specification is 150X25X4mm, 800 watts, heated to 1000° C. in 10 seconds.

[0070] Among the weight ratios of the three ceramic materials,

[0071] 1. Insulating ceramic material: silicon nitride Si 3 N 4 , 91.5%; Ytterbium oxide Y 2 o 3 , 1-3%; aluminum oxide Al 2 o 3 , 0.5-1.5%; magnesium oxide MgO, 0.2-0.5%; lanthanum trioxide La 2 o 3 , 0.5-1%; hafnium oxide HfO 2 , 0.2-0.5%, aluminum nitride AlN, 0.5-2%, the weight of all components is 100%.

[0072] 2. Heating ceramic material: silicon nitride Si 3 N 4 , 45%, solid solution of titanium carbide and titanium nitride, Ti (C, N), 26-35%; the weight ratio of titanium carbide and titanium nitride in the solid solution is 4:6; molybdenum powder Mo, 0.5-3%; Nano nickel Ni, 0.5-1.0%; Niobium carbide CHNb, 0.2%; Whisker silicon carbide SiC, 0.2-0.5%; Molybdenum silicide MoSi 2 , 0.1-0.2%; silicon oxide SiO 2 , 0.1-0.2%; alumina Al 2 o 3 , 5-10%, the weight of all componen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com