Micro-sized small-power impeller-type aerator

A low-power, impeller-type technology, applied in fish farming, application, animal husbandry, etc., can solve the problems that the aerator cannot meet the needs of small farmers, insufficient oxygenation capacity, and small water volume, and can improve the dissolved oxygen and Breeding effect, spray evenly distributed, spray far away

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing, the present invention will be further described as follows:

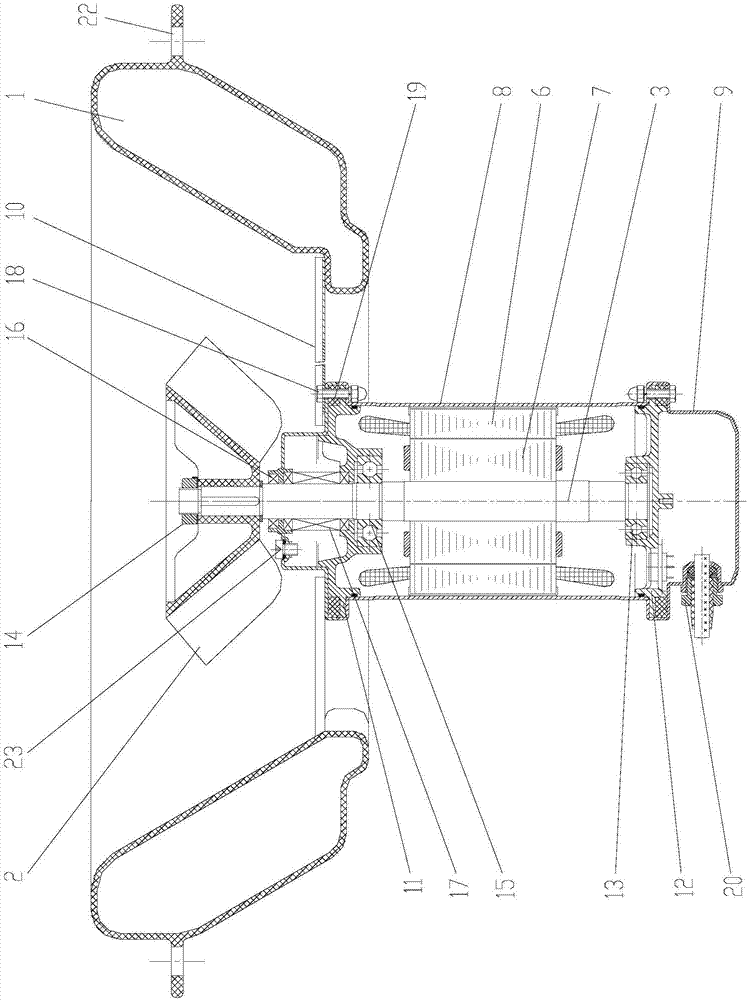

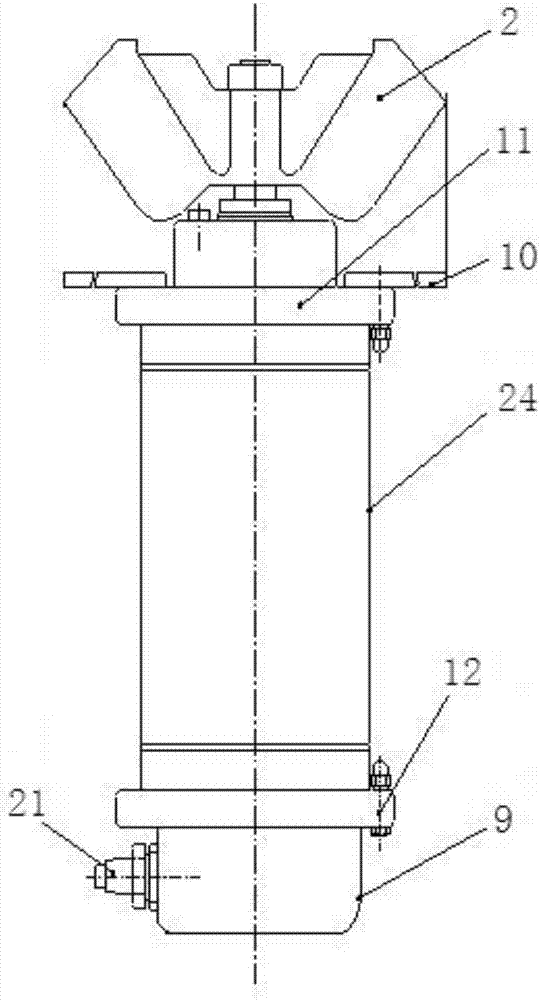

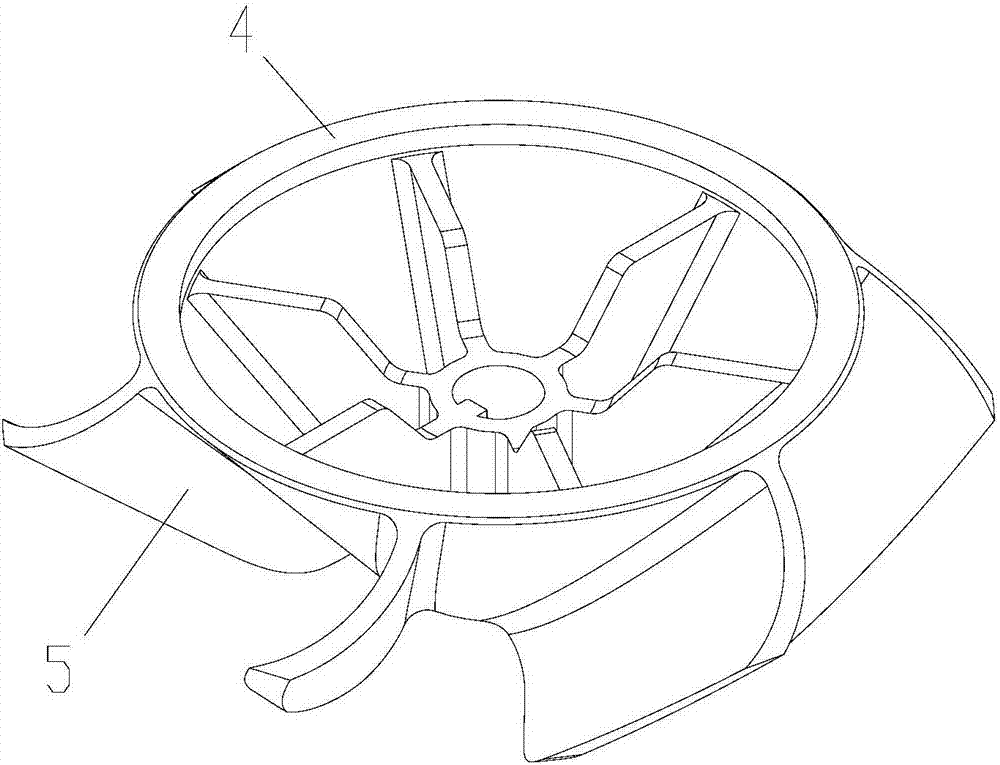

[0030] As shown in the accompanying drawings, the present invention includes: a floating body 1, a motor 24, and an impeller 2. The motor 24 is a three-phase 380V or single-phase 220V capacitor-starting capacitor-operated motor, and the floating body 1 is made of polyethylene plastic. It has a hollow ring-shaped structure with edges and a concave center. The impeller 2 is set at the center of the floating body 1. A motor 24 is installed under the floating body 1. The impeller 2 is connected to the rotating shaft 3 of the motor 24. The impeller 2 is driven by the rotor body 4. and a plurality of blades 5, the rotor body 4 is arranged in the middle, and the blades 5 are evenly distributed around the rotor body 4 along the circumferential direction. 2. Under the drive of the motor 24, the water flow is sprayed into the air from the bottom to the oblique top and spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com