Bottom heated baking pan and light wave electric oven using the baking pan

A technology for bottom heating and baking trays, which is applied in the direction of baking special containers, applications, roasters/barbecue grids, etc., which can solve the problems of difficult heating pipes, slow heat conduction heating efficiency, and affecting food insulation in baking trays, etc., to achieve faster speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

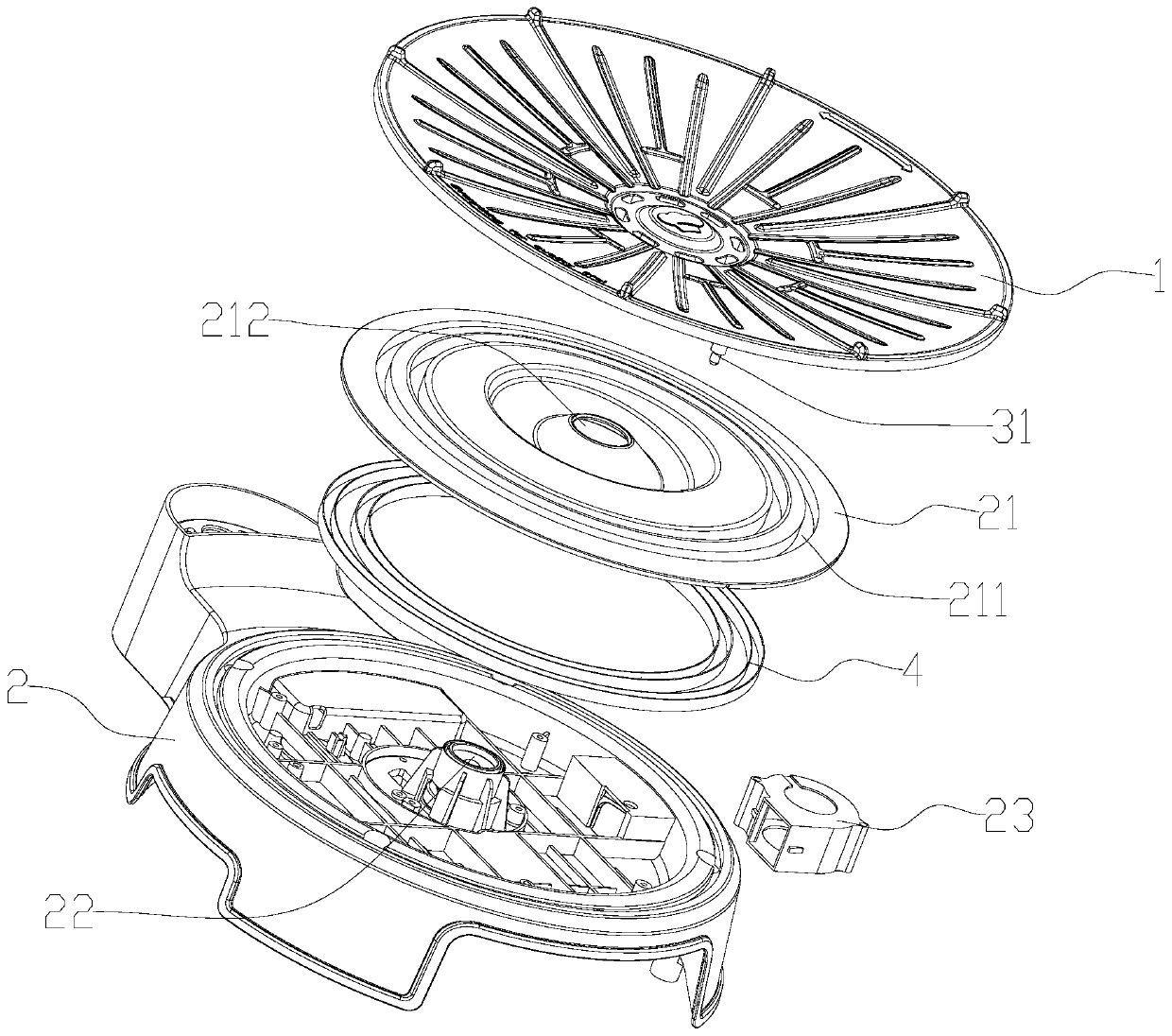

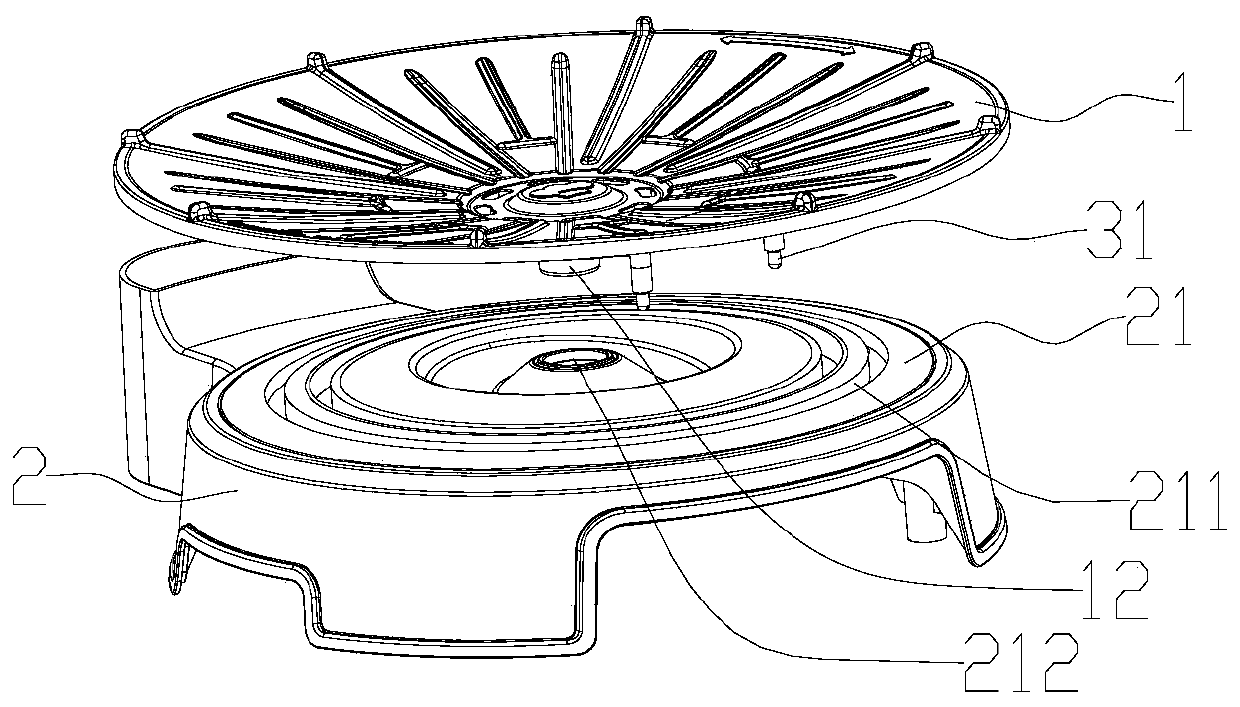

[0022] A bottom heating pan and a light-wave electric oven using the pan are described in conjunction with the accompanying drawings.

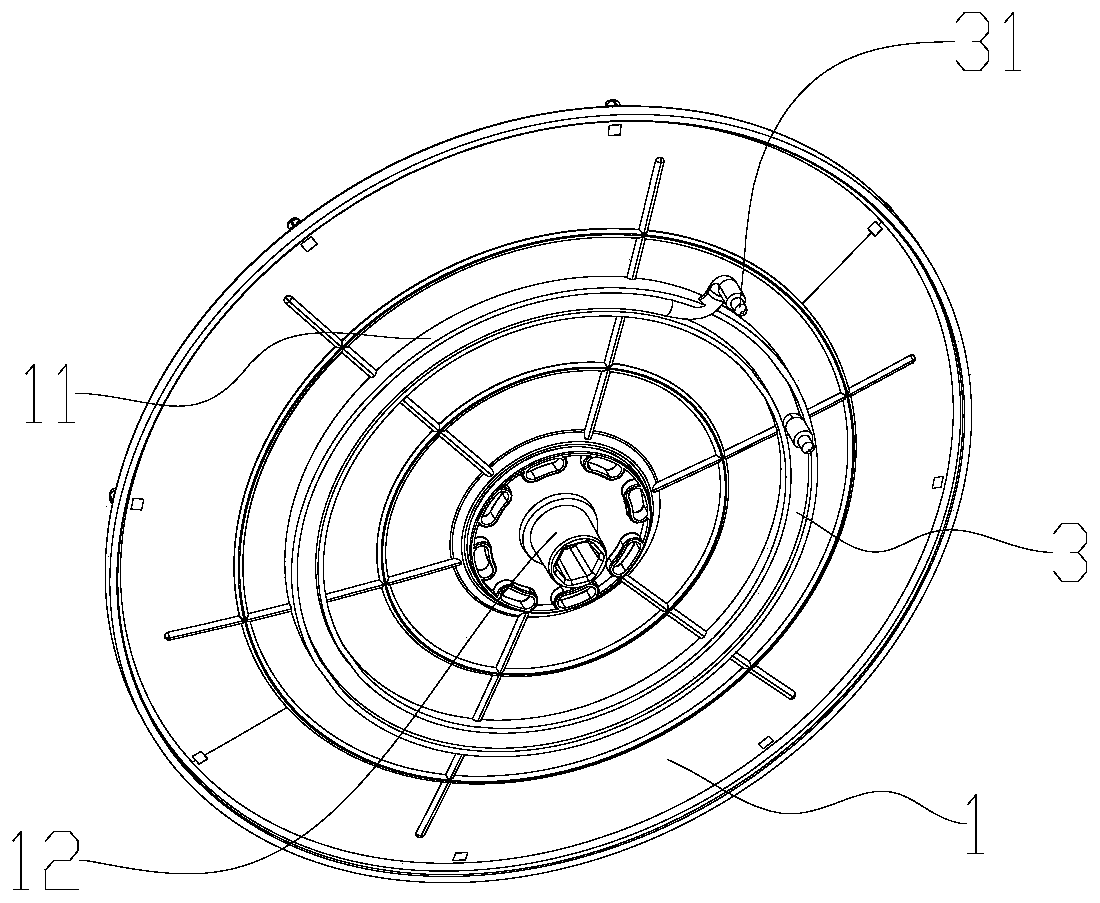

[0023] A bottom heating baking pan and a light-wave electric oven using the baking pan, such as Figures 1 to 4 As shown, it includes a baking pan 1, a base 2 for installing the baking pan 1, and a light-wave heat source 5. The light-wave heat source 5 is fixed on the base 2 through a support structure 6 and is set overhead on the top of the baking pan 1. The baking pan 1 can be It is installed in rotation on the base 2; it also includes a heating tube 3, the heating tube 3 is arranged on the bottom surface of the baking pan 1, and an electrode 31 extends to the base 2 of the baking pan 1, and the base 2 is provided with a power supply structure, The power supply structure connects the electrodes 31 to supply power to the heating tube 3 .

[0024] further, Figures 2 to 3 As shown, the bottom surface of the baking pan 1 is provided with a ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com