Heating water tank special for water-based spraying workshop in cold region

A technology for heating water tanks and cold areas, which is used in household heating, heating methods, and household heating. , The effect of reducing power consumption and uniform and continuous hot water temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

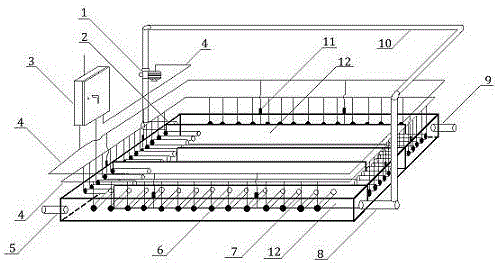

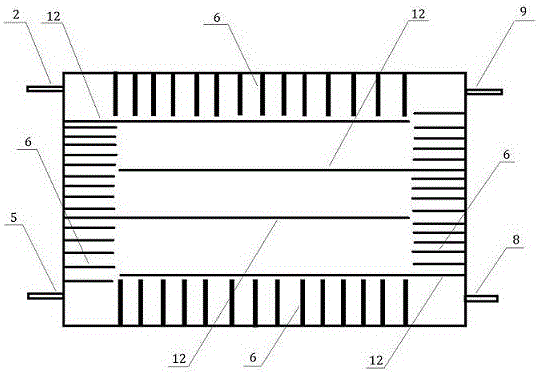

[0027] The heating water tank is specially used for the water-based spraying workshop in cold areas. It is made of steel plate and is located under the water-based spraying workshop as a whole. The lower steel plate is at the same level as the ground outside the water-based spraying workshop, and there are a number of staggered and juxtaposed vertical steel plates between the upper and lower steel plates as support plates 12, and there are evenly distributed resistance heating rods 6 on the surrounding walls of the box, which are connected in parallel to each other in the circuit , the water storage in the heating water tank is heated by converting electric energy into heat energy, wherein there are circulating water outlet 2, circulating wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com