Automatic correction device for grinding wheels of glass edge grinding machine

An automatic correction and glass edging technology, which is used in grinding drive devices, machine tools suitable for grinding workpiece edges, and parts of grinding machine tools, etc. Low efficiency and other problems, to achieve the effect of improving reliability, simple and reliable operation principle, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

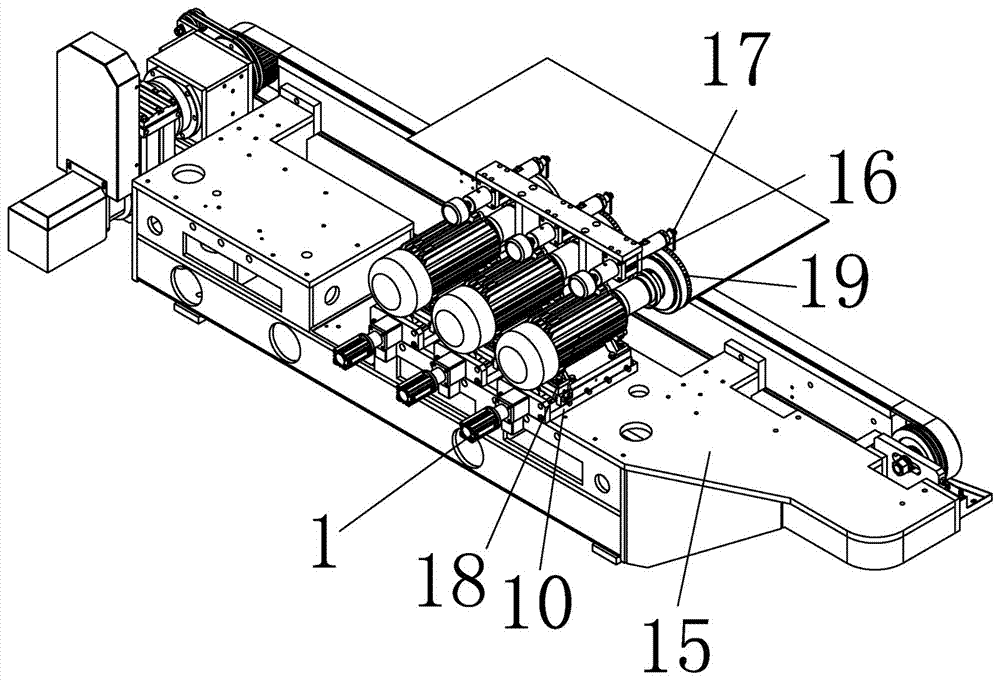

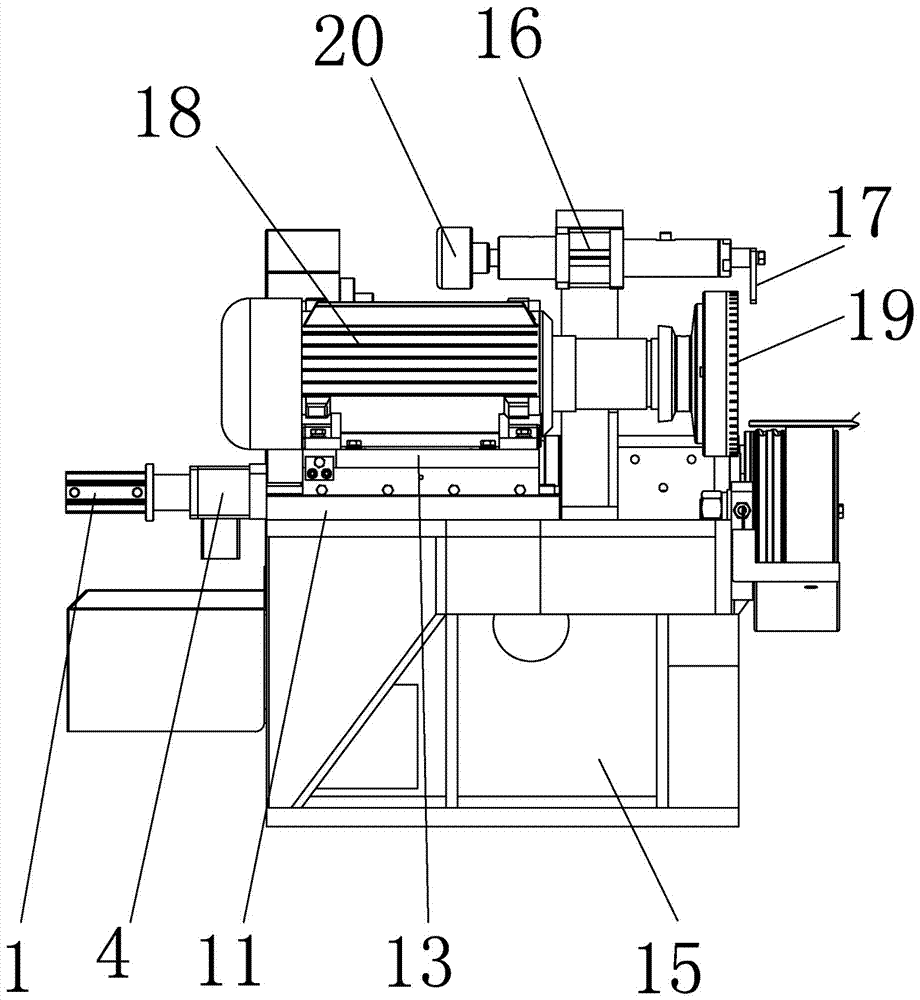

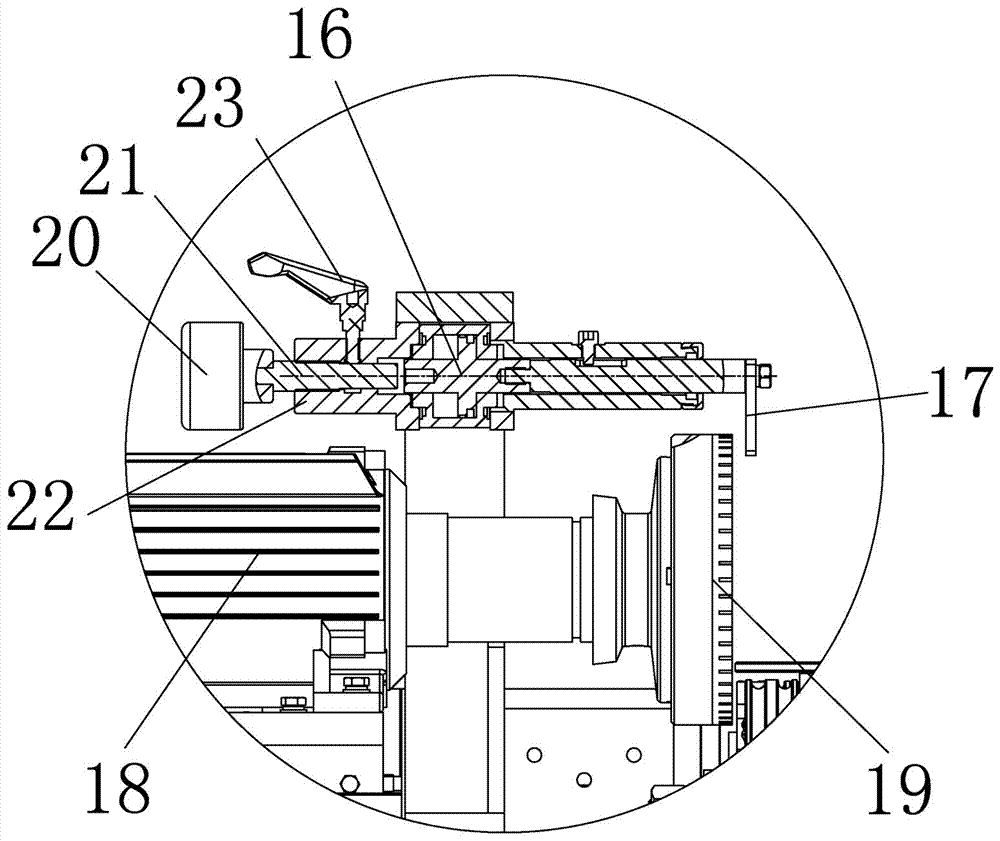

[0023] The present invention will be specifically and further described below in conjunction with the accompanying drawings. A glass edging machine grinding wheel automatic correction device is characterized in that it includes a motor drive device and a grinding wheel positioning device installed on the machine tool body 15, wherein the motor drive device includes a base 11 and a guide rail arranged on it 12. A sliding plate 13 is installed above the guide rail 12, the base 11 is fixedly connected with the machine tool, the motor is installed on the sliding plate 13, the main cylinder 1 is installed on the base 11, and the piston rod 3 of the main cylinder 1 is fixed to the sliding plate 13 Installation, the master cylinder 1 drives the sliding plate 13 to slide back and forth on the base 11 through the piston rod 3, the master cylinder 1 is provided with a cylinder locking device, when the master cylinder 1 moves in place, the piston rod 3 is locked to limit the sliding plate...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap