Back packing system and back packing method

A packaging system and packaging method technology, applied in the field of packaging, can solve the problems of low efficiency, high labor intensity, and prone to leaks, and achieve the effects of improving packaging efficiency, increasing economic benefits, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

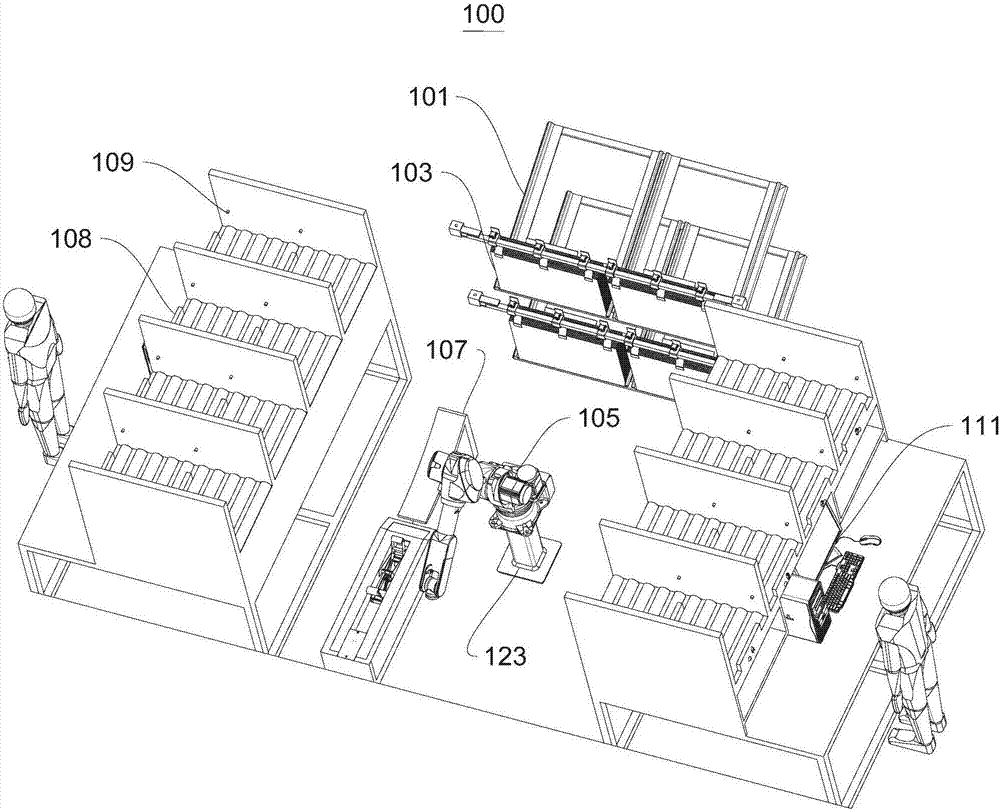

[0049] refer to figure 1 , the present embodiment provides a downstream packaging system 100, including a storage device 101, a robot 105, a bottom sealing mechanism 107, a storage mechanism 108, a detection device 109 and a control system 111 arranged in sequence.

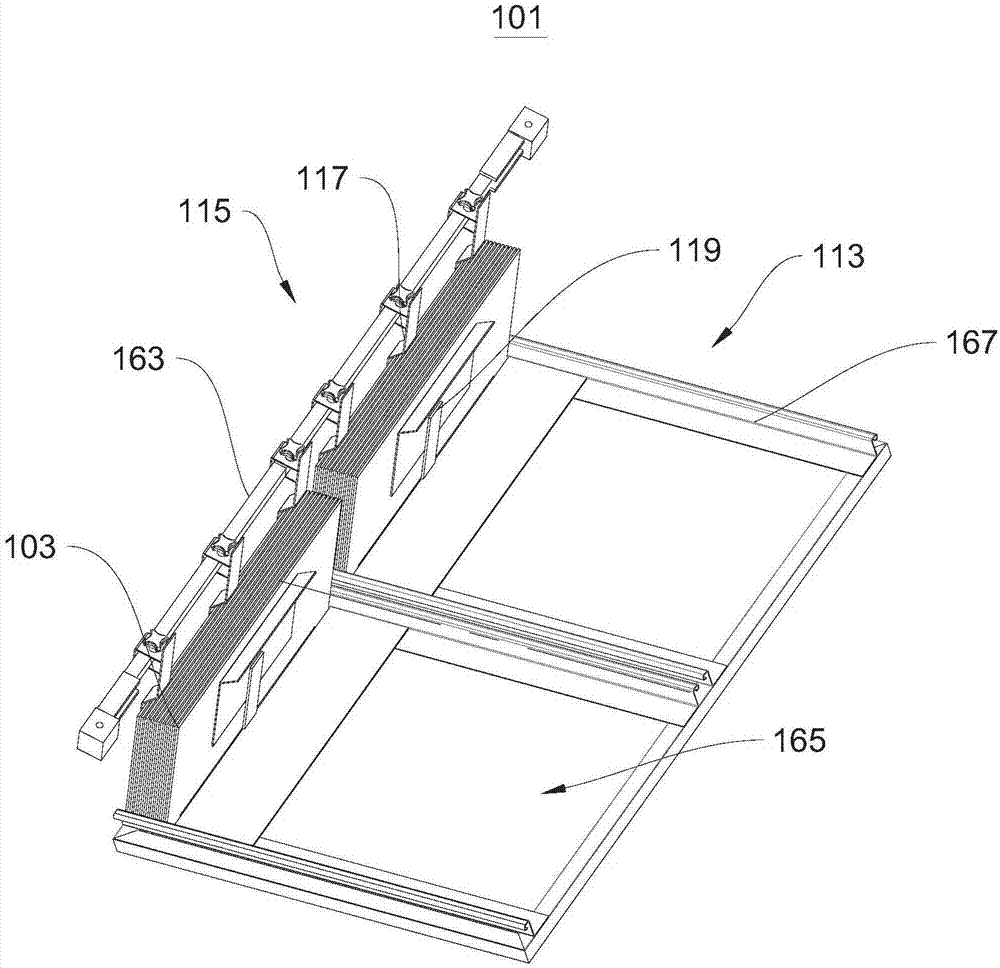

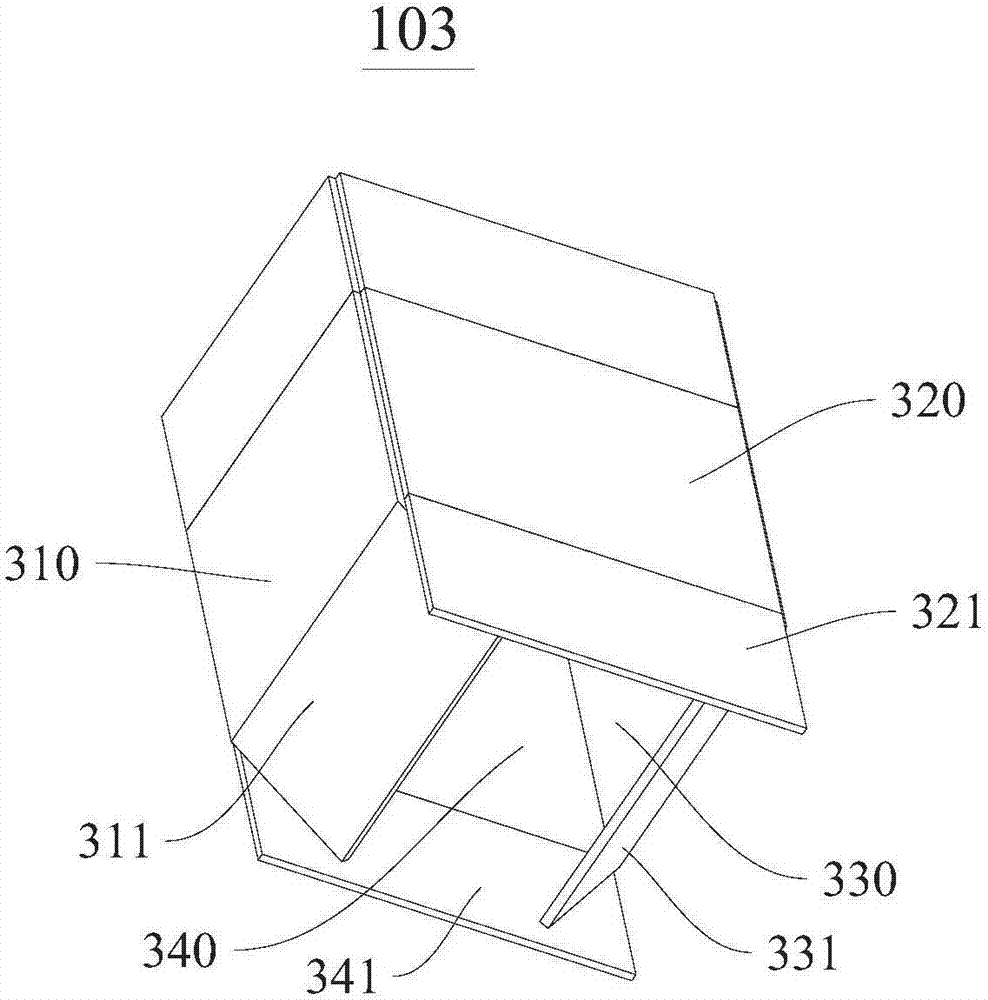

[0050] In this example, see figure 1 and figure 2 The storage device 101 is used to store cartons 103 of different sizes. The storage device 101 can be any device that can be selected to provide a storage function. For example, it can be a storage rack. The size is divided into storage spaces. As a preferred option, see figure 1 and figure 2 The material storage device 101 includes a material storage rack 113 and a limiting mechanism 115 arranged on the material storage rack 113 and used to fix and limit the position of the carton 103 .

[0051] Specifically, see figure 2 , the storage rack 113 includes a plurality of beams 163 and a plurality of support plates 165 . Each crossbeam 163 can be fixed by a ...

Embodiment 2

[0083] refer to Figure 9 and Figure 10 The difference between the downstream packaging system 200 provided in this embodiment and the downstream packaging system 100 is that the downstream packaging system 200 further includes a capping mechanism 151 for capping the cartons 103 after packing.

[0084] In this example, see again Figure 10 The capping mechanism 151 includes a guide mechanism 153 connected to each other, a capping device 155 and a second transmission system 209 for transferring the carton 103, the guide mechanism 153 includes a guide rod 157, and is used to drive the guide rod 157 to fold the first top plate assembly of the carton 103 The driver 159 of 201 and the third guide 158 of the second top plate assembly 203 for folding the carton 103. The top capping device 155 is used for connecting the folded first top panel assembly 201 and the second top panel assembly 203 .

[0085] Specifically, the guide mechanism 153 is installed above the work frame 207, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com