Large-load rope climbing mechanism based on special-shaped chain wheel transmission

A sprocket drive, large load technology, applied in the direction of transmission chain, transmission device, belt/chain/gear, etc., can solve the problems of small lifting heavy load, easy to be worn by rope bending, poor safety and reliability, etc. Operation lift and drop effect, light weight, smooth motion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

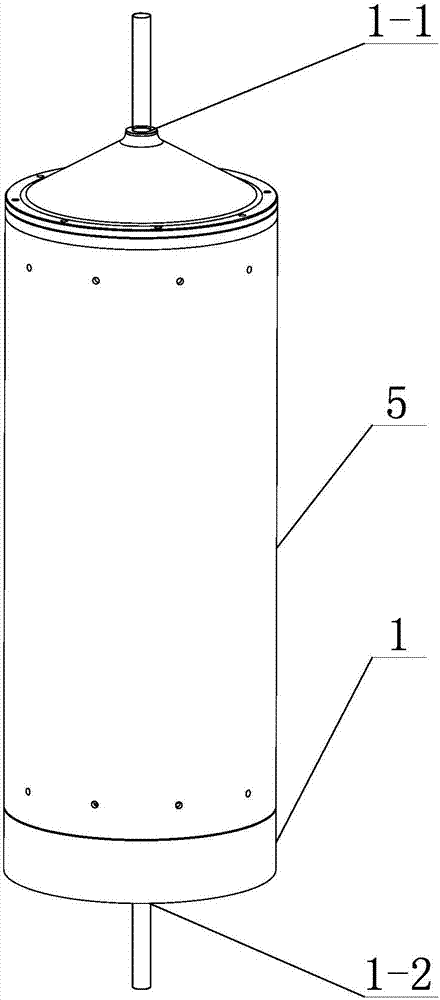

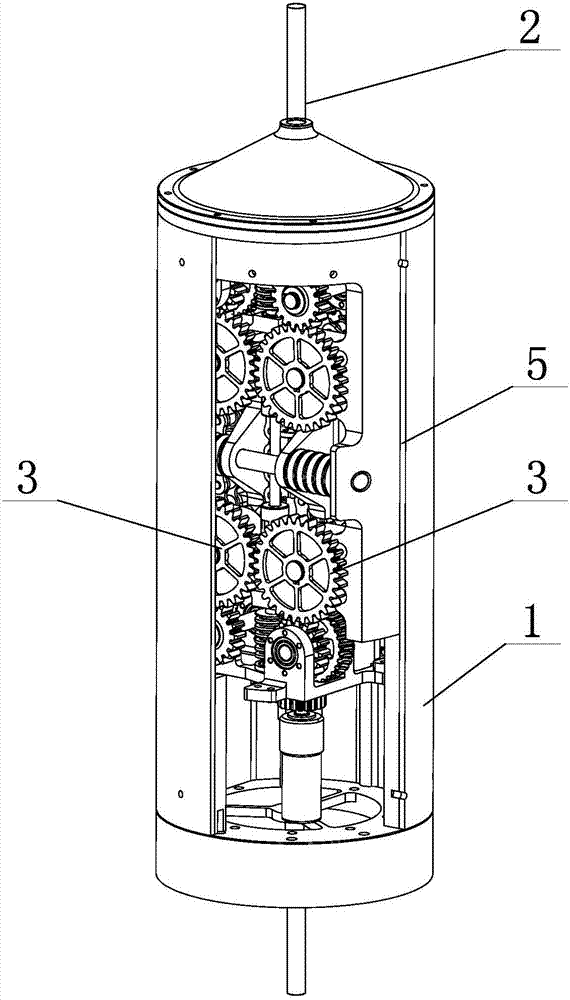

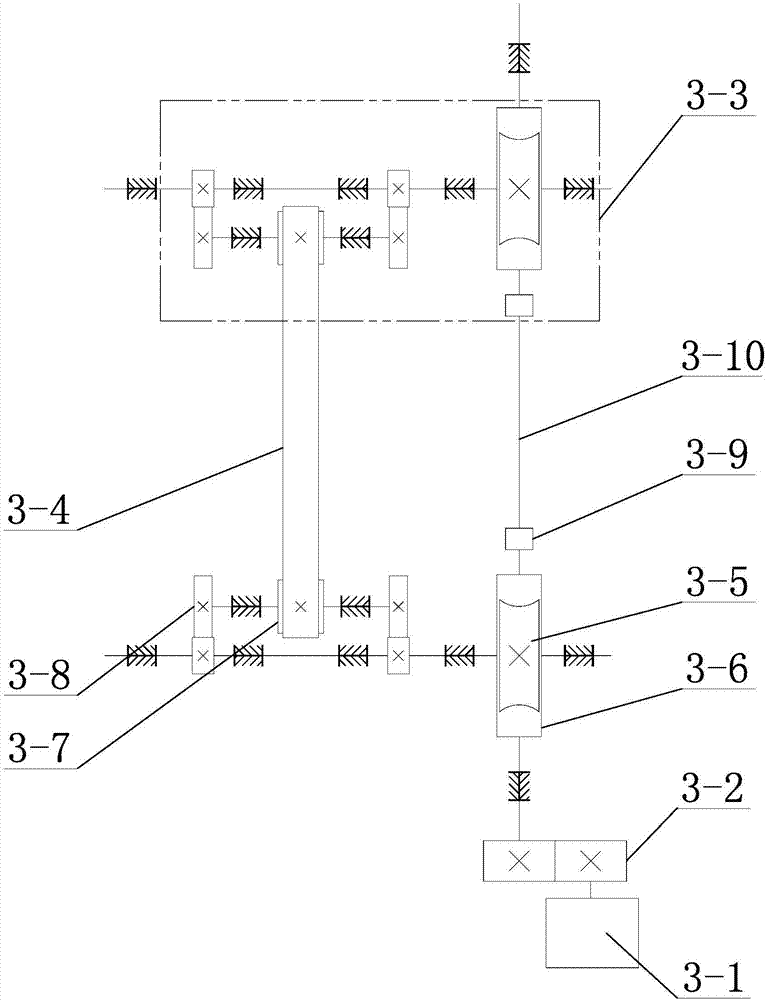

[0025] Specific implementation mode one: combine figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 with Figure 10 Describe this embodiment. This embodiment includes a main body support 1, a rope 2 and two sets of transmission systems 3. The two sets of transmission systems 3 are arranged side by side inside the main body support 1. The two sets of transmission systems 3 have the same structure. The transmission system 3 includes a motor 3-1, a first gear adjustment assembly 3-2, a special-shaped chain 3-4 and two sprocket assemblies 3-3, and the two sprocket assemblies 3-3 are along the sides of the main body support 1. The length direction is juxtaposed, and each sprocket assembly 3-3 includes a worm gear 3-5, a worm screw 3-6, a special-shaped sprocket 3-7 and two second gear adjustment assemblies 3-8, and the worm gear 3-5 and The worms 3-6 are meshed, the two second gear adjustment assemblies 3-8 are coaxially ...

specific Embodiment approach 2

[0029] Specific implementation mode two: combination figure 2 Describe this embodiment. In this embodiment, the main body support 1 is arranged vertically. The top of the main body support 1 is processed with an upper opening 1-1, and the bottom of the main body support 1 is processed with a lower opening 1-2. One end of the rope 2 passes through the upper opening 1-1, and the other end of the rope 2 passes through the gap between the two special-shaped chains 3-4 and the lower opening 1-2 at the bottom of the main body support 1 in turn, so Said rope 2 reciprocates between the upper port 1-1 and the lower port 1-2 driven by two special-shaped chains 3-4. Other unmentioned structures and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0030] Specific implementation mode three: combination Figure 2 to Figure 9Describe this embodiment, in this embodiment, each special-shaped chain 3-4 is made up of a plurality of chain links 3-4-1 and a plurality of connecting pieces 3-4-2, and each chain link 3-4-1 is provided with Two connecting shafts 3-4-3, the outer end surface of each chain link 3-4-1 is processed with a placement groove 3-4-4 matched with the rope 2, a plurality of chain links 3-4-1 A rope clamping channel is formed between the placement grooves 3-4-4, and each chain link 3-4-1 is connected to the two adjacent chain links 3-4-1 through four connecting pieces 3-4-2. connection, the ends of the two connecting shafts 3-4-3 on each chain link 3-4-1 are respectively provided with a connecting piece 3-4-2, and the ends of each connecting shaft 3-4-3 It is hinged to the connecting shaft 3-4-3 on the adjacent chain link 3-4-1 through its corresponding connecting piece 3-4-2.

[0031] In this embodiment, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com