Method for preparing concrete with alumina industrial waste

A technology of industrial waste and concrete, applied in the direction of solid waste management, sustainable waste treatment, climate sustainability, etc., can solve the problems of easy floating of fly ash particles, large concrete porosity, increased internal bonding, etc., to achieve effective Conducive to industrial production and promotion, good corrosion resistance and high replacement rate

Inactive Publication Date: 2017-08-18

辽宁坚峰实业有限公司

View PDF4 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0008] 1. When the concrete slumps too much, the fly ash particles are easy to float up and cause slurry bleeding

[0009] 2. The early strength of concrete is low, and at low temperature, a large amount may cause slow setting

[0010] 3. The porosity of concret

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

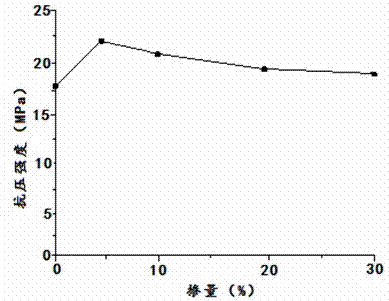

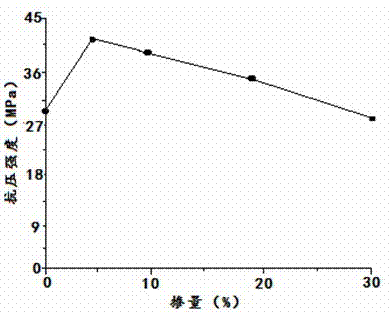

The invention provides a method for preparing concrete with alumina industrial waste. The method is characterized in that 0-40% of cement is equivalently replaced with an activated red mud mixture at a mass ratio based on reference mixing ratios of common concrete, wherein the red mud mixture comprises red mud and magnesite powder; an addition ratio of the magnesite powder accounts for 0-10% of the red mud mixture; and the method comprises the following steps of drying, raw material weighing, grinding, mixing, roasting, red mud concrete preparation and the like. The concrete prepared with the method has high strength, high replacement rate, good durability, and no toxic or side effect; the preparation method is simple; industrial production and popularization are facilitated; raw materials are low in cost; the applicability is wide; and the method has obvious economic benefits, environmental benefits and social benefits.

Description

technical field [0001] The invention relates to the technical field of post-processing of industrial waste, in particular to a method for preparing concrete from alumina industrial waste. Background technique [0002] As we all know, the polluting solid waste discharged from the aluminum industry after extracting alumina is red mud. For every ton of alumina produced, 1 to 2 tons of red mud will be produced. With the development of the aluminum industry, more than 70 million tons of red mud are produced every year in the world. my country is a big country in the aluminum industry, and more than 30 million tons of red mud are produced every year. Red mud is divided into Bayer process red mud, sintering process red mud, and combined process red mud according to the different production processes of alumina. The chemical composition is shown in Table 1. [0003] Table 1 Chemical composition of red mud in different processes (%) [0004] red mud name SiO2 Al2O3 F...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C04B28/00C04B18/04

CPCY02W30/91C04B28/00C04B18/0409C04B40/0046C04B2201/50C04B14/06C04B18/12C04B2103/0068C04B14/26

Inventor 武斌

Owner 辽宁坚峰实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com