High-lighting-effect and high-stability alpha-SiAlON:Eu<2+> yellow fluorescent powder and preparation method thereof

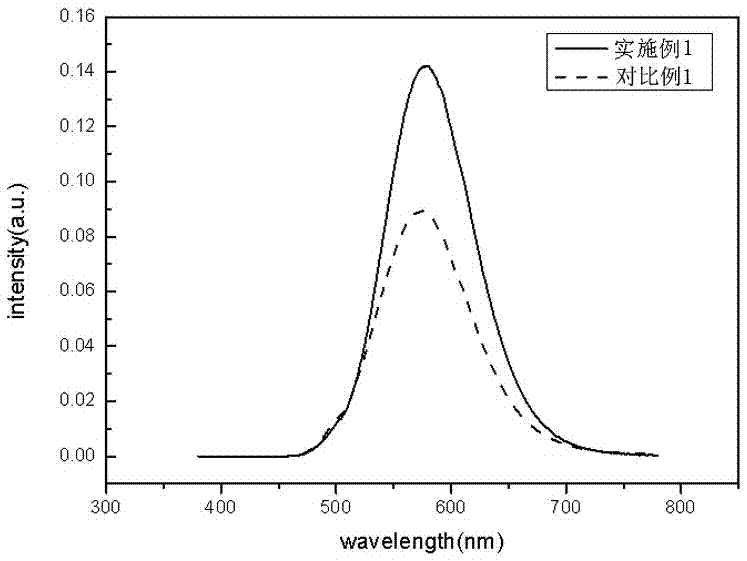

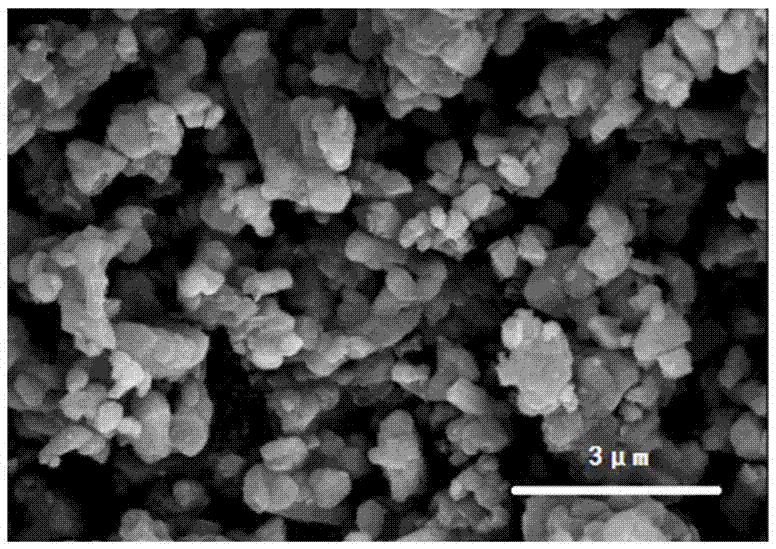

A technology of yellow phosphor and high stability, which is applied in the field of yellow phosphor and its preparation, which can solve the problems of poor stability and insufficient brightness of yellow phosphor, and achieve increased crystallinity, thermal quenching and high temperature and high humidity resistance The effect of stability improvement and size increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Si 9.6 (Ca 0.15 Ti 0.85 ) 1.2 (Al 0.35 In 0.65 ) 2.4 o 0.2 N 15.8 : 0.06Eu 2+ Preparation of yellow phosphor powder:

[0030] (1) According to Si 3 N 4 : Ca 3 N 2 :AlN:TiO 2 : In 2 o 3 :Eu 2 o 3 = 3.20: 0.06: 0.84: 1.02: 0.78: 0.03 molar ratio respectively weighs the corresponding amount of Si 3 N 4 , Ca 3 N 2 , AlN, TiO 2 、In 2 o 3 and Eu 2 o 3 As raw material; weigh CaCl 2 As a sintering aid, its dosage is 1% of the total mass of raw materials.

[0031] Note: All the above raw materials and additives need to be weighed in the glove box N 2 Under the atmosphere (water content 3 N 2 ) absorbs water and oxygen severely, resulting in changes in its chemical properties.

[0032] (2) Put the weighed raw materials and auxiliary agents into a corundum mortar and make them fully mix, then pass through a 50-mesh sieve, and put them into a W crucible (the melting point of the W crucible is higher than 3000°C, which can meet the requirements of use, ...

Embodiment 2~10、 comparative example 2

[0041] According to the process conditions and steps in Example 1, the types and doping amounts of M1 and M2 were changed to prepare different phosphors. The prepared fluorescent powder was tested with a HASS2000 high-precision fast spectroradiometer, and the results are shown in Table 1.

[0042] Table 1:

[0043]

[0044]

Embodiment 11~17

[0046] According to the process conditions and steps in Example 1, the types of additives used were changed to prepare phosphors. Adopt HASS2000 high-precision fast spectroradiometer to test the prepared fluorescent powder, the obtained results are shown in Table 2, in the table, D50 is the central particle diameter of the obtained fluorescent powder, K is the particle size distribution coefficient, and its calculation method is K=( D90-D10) / D50.

[0047] Table 2:

[0048] Example number Additive type relative brightness wxya peak wavelength D50(μm) K Example 11 NaF 175.2 90.1 573.4 0.82 1.23 Example 12 KF 173.2 90.2 573.4 0.95 1.20 Example 13 AlF 3

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap