Domestic tableware 8006 alloy thin foil and preparing method thereof

A double-zero foil and alloy technology, which is applied in the field of household tableware 8006 alloy double-zero foil and its preparation, can solve the problems of large pollution, high cost and unattainable surface quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

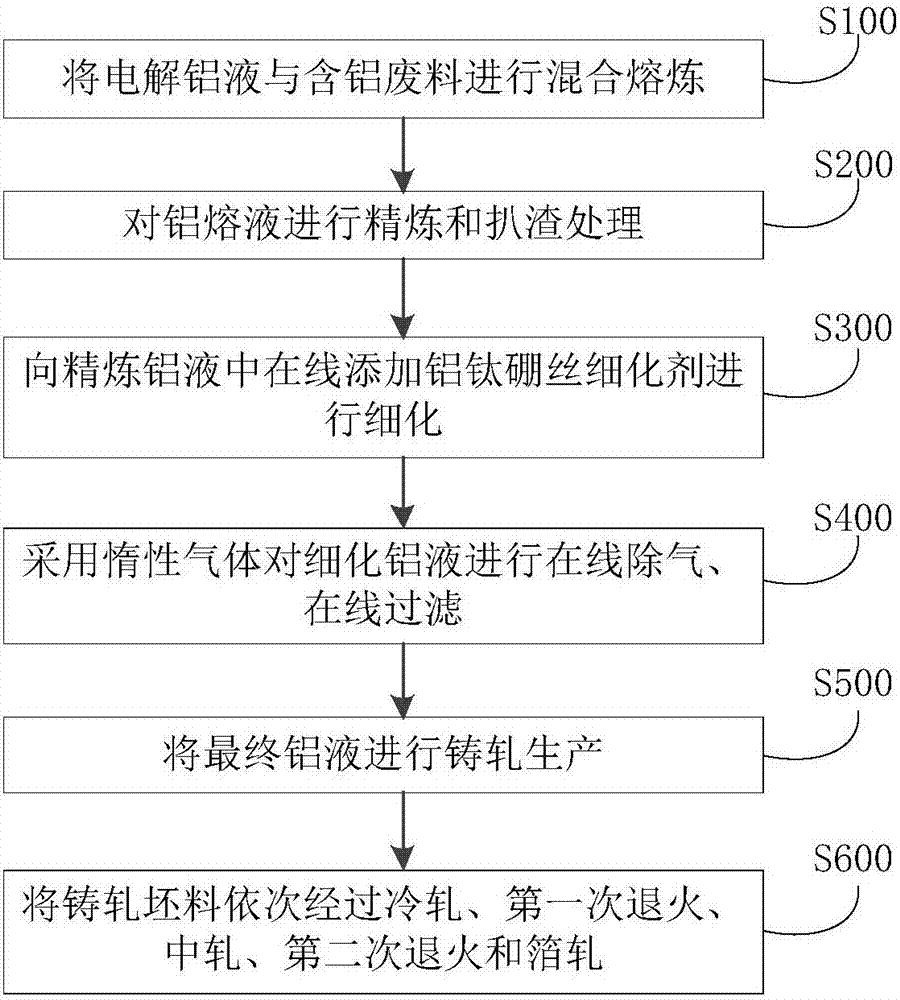

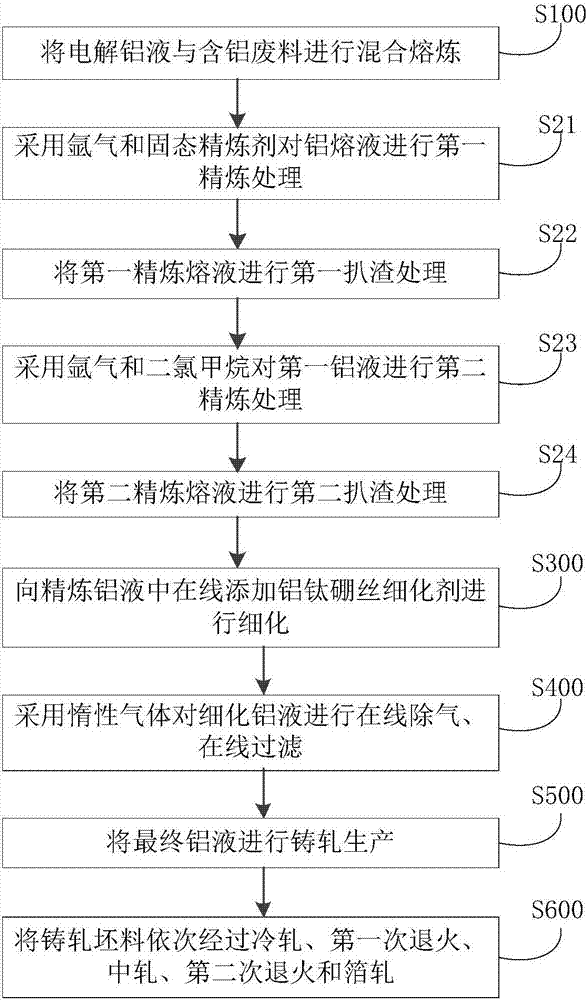

Method used

Image

Examples

Embodiment 1

[0069] The chemical composition and weight percentage of 8006 alloy are shown in Table 1.

[0070] Table 1 Chemical composition and weight percentage of 8006 alloy

[0071] alloy Fe(wt%) Si(wt%) Cu(wt%) Zn(wt%) Mn(wt%) Ti(wt%) Al(wt%) 8006 1.42 0.20 0.10 0.01 0.33 0.035 margin

[0072] The chemical composition of the aluminum melt is strictly in accordance with the 8006 alloy, using 70wt% electrolytic aluminum liquid mixed with 30wt% aluminum-containing scrap. During the smelting process of the aluminum melt, when the temperature of the aluminum melt reaches 710 degrees Celsius, remove the surface scum and use Electromagnetic stirring is used to stir the molten aluminum. When the temperature of the molten aluminum reaches 735 degrees Celsius, sampling and analysis are carried out to configure the chemical composition.

[0073] In the refining process of molten aluminum, multi-pass refining technology is adopted. When the temperature of...

Embodiment 2

[0080] The chemical composition and weight percentage of 8006 alloy are shown in Table 2.

[0081] Table 2 Chemical composition and weight percentage of 8006 alloy

[0082] alloy Fe(wt%) Si(wt%) Cu(wt%) Zn(wt%) Mn(wt%) Ti(wt%) Al(wt%) 8006 1.5 0.23 0.09 0.03 0.31 0.035 margin

[0083] The chemical composition of the molten aluminum is strictly in accordance with the 8006 alloy, using 65wt% electrolytic aluminum liquid mixed with 35wt% aluminum-containing scrap. During the smelting process of the molten aluminum, when the temperature of the molten aluminum reaches 705 degrees Celsius, remove the surface scum and use Electromagnetic stirring is used to stir the aluminum, and when the temperature of the molten aluminum reaches 740 degrees Celsius, sampling and analysis are carried out to configure the chemical composition.

[0084] In the refining process of molten aluminum, multi-pass refining technology is adopted. When the temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap